BOPP thin film for shallow reticulated printing

A kind of shallow screen printing and film technology, applied in the field of biaxially oriented polypropylene film and BOPP film, it can solve the problems of poor ink adhesion and antistatic performance, affecting color printing effect, mesh hole blocking and other problems, achieving low static electricity and excellent Antistatic properties, precise rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

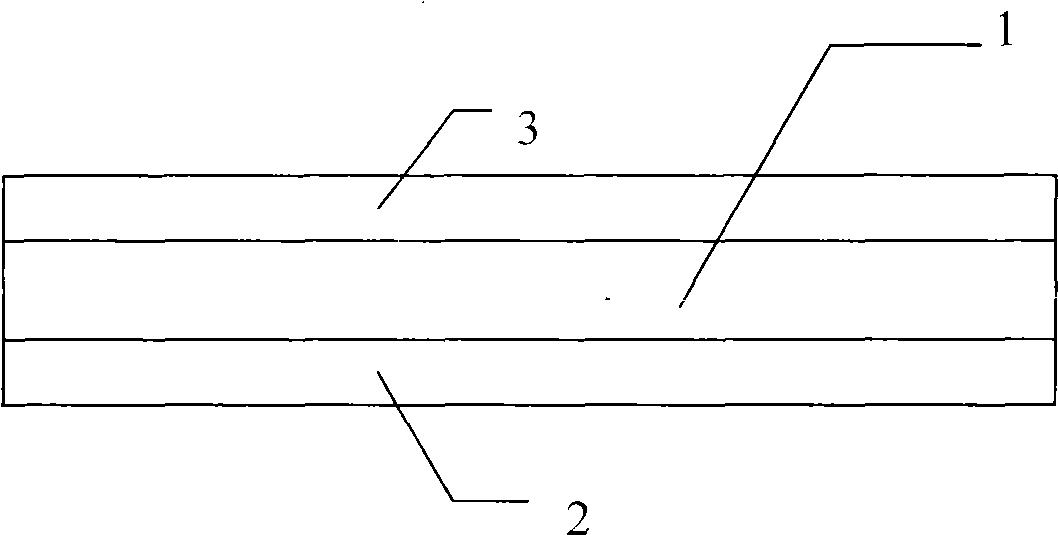

[0018] Use biaxially stretched polypropylene resin to form a film with a three-layer structure after co-extrusion and biaxial stretching, anti-blocking layer 3, core layer 1 and shallow screen printing layer 2, such as figure 1 As shown, the shallow screen printing layer 2 is a corona treated surface.

[0019] The shallow screen printing layer contains 2% of synthetic silica by weight, and the rest is polypropylene resin. The particle size ranges of synthetic silica are: 1-2 μm and 2-4 μm, and the ratio of the two is 0.5:3.5. The thickness of the shallow screen printing layer is 0.8-1.0 μm.

[0020] The anti-adhesion layer contains 5% of synthetic silica by weight, and the rest is polypropylene resin; the particle size of the synthetic silica is 3-5 μm. The thickness of the anti-adhesion surface layer is 0.8-1.0 μm,

[0021] The core layer contains 0.8% of antistatic agent by weight, and the rest is polypropylene resin. The thickness of core layer is 14~40μm

[0022] Both...

Embodiment 2

[0024] Use biaxially stretched polypropylene resin to form a film with a three-layer structure after co-extrusion and biaxial stretching, anti-blocking layer 3, core layer 1 and shallow screen printing layer 2, such as figure 1 As shown, the shallow screen printing layer 2 is a corona treated surface.

[0025] The shallow screen printing layer contains 4% of synthetic silica by weight, and the rest is polypropylene resin. The particle size ranges of synthetic silica are 1-2 μm and 2-4 μm respectively, and the ratio of the two is 1.5:4.5. The thickness of the shallow screen printing layer is 0.8-1.0 μm.

[0026] The anti-adhesion layer contains 3% of synthetic silica by weight, and the rest is polypropylene resin; the particle size of the synthetic silica is 3-5 μm. The thickness of the anti-adhesion surface layer is 0.8-1.0 μm,

[0027] The core layer contains 1% antistatic agent by weight, and the rest is polypropylene resin. The thickness of the core layer is 14-40 μm. ...

Embodiment 3

[0029] Use biaxially stretched polypropylene resin to form a film with a three-layer structure after co-extrusion and biaxial stretching, anti-blocking layer 3, core layer 1 and shallow screen printing layer 2, such as figure 1 As shown, the shallow screen printing layer 2 is a corona treated surface.

[0030] The shallow screen printing layer contains 3% of synthetic silica by weight, and the rest is polypropylene resin. The particle size ranges of synthetic silica are: 1-2μm and 2-4μm, and the ratio of the two is 1:4. The thickness of the shallow screen printing layer is 0.8-1.0 μm.

[0031] The anti-adhesion layer contains 4% of synthetic silica by weight, and the rest is polypropylene resin; the particle size of the synthetic silica is 3-5 μm. The thickness of the anti-adhesion surface layer is 0.8-1.0 μm,

[0032] The core layer contains 0.9% of antistatic agent by weight, and the rest is polypropylene resin. The thickness of the core layer is 14-40 μm.

[0033] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com