Multichannel high speed special metal cover gluing mechanism

A special-shaped metal, cover coating technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem of uneven instantaneous line speed of the glue injection head, unsuitable for high-speed operation, and uneven thickness of glue injection. Good uniformity of glue thickness, good sealing performance and uniform contact stress

Inactive Publication Date: 2011-01-05

黄锐龙

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main purpose of the present invention is to provide an improved multi-channel high-speed special-shaped metal can lid gluing mechanism, which can overcome the existing similar special-shaped metal can lid gluing device, which can only be applied to one special-shaped metal can lid at a time. Gluing, the defect of low work efficiency

Another purpose of the present invention is to provide a further improvement on this basis, which can overcome the vibration and offset of components existing in the existing similar special-shaped metal can lid gluing device when encountering a small corner of the can lid special-shaped curve However, it affects the accuracy of the injection trajectory, and the instantaneous line speed of the injection head is uneven, resulting in uneven thickness of the injection, and is not suitable for high-speed operations.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

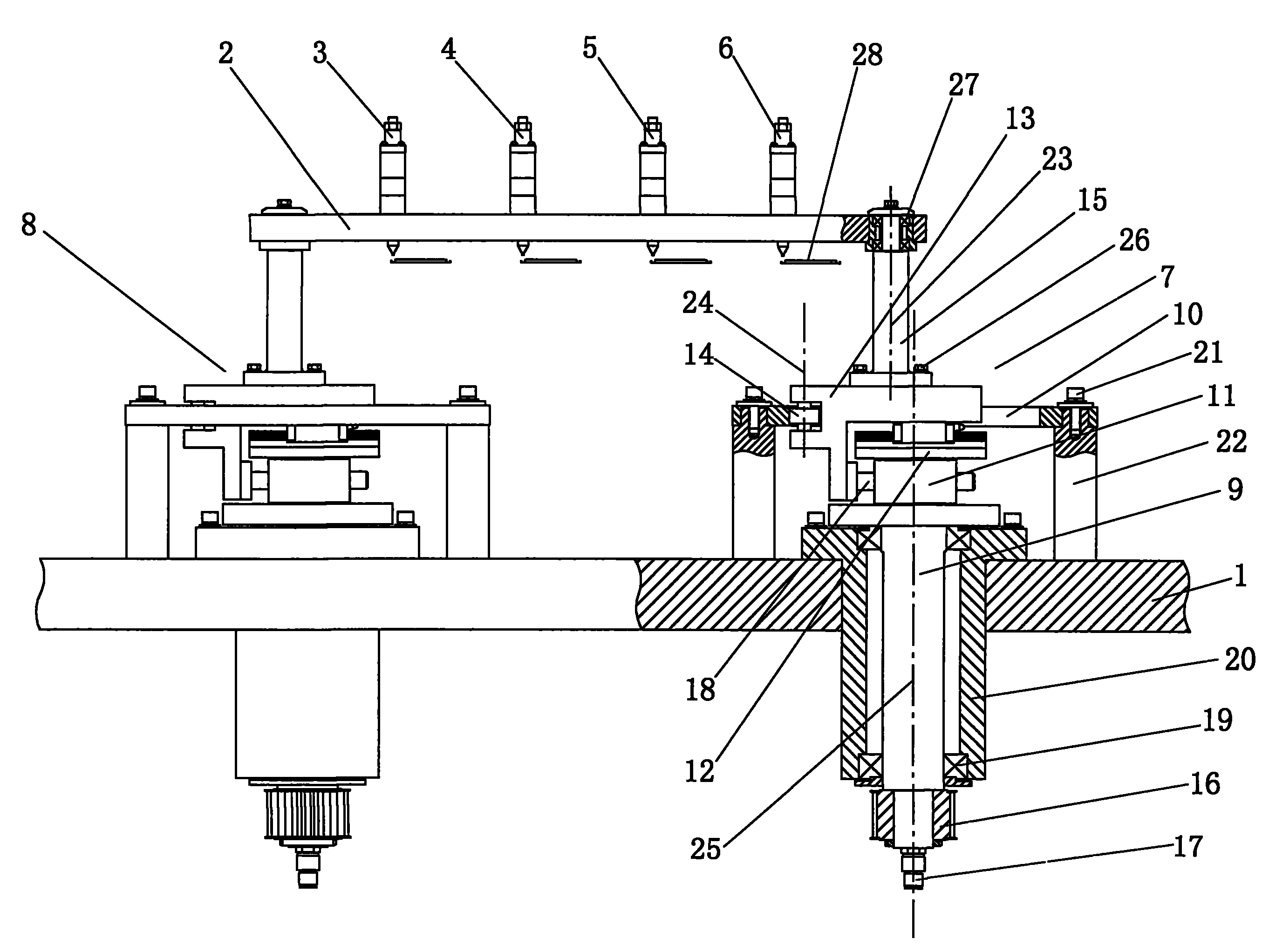

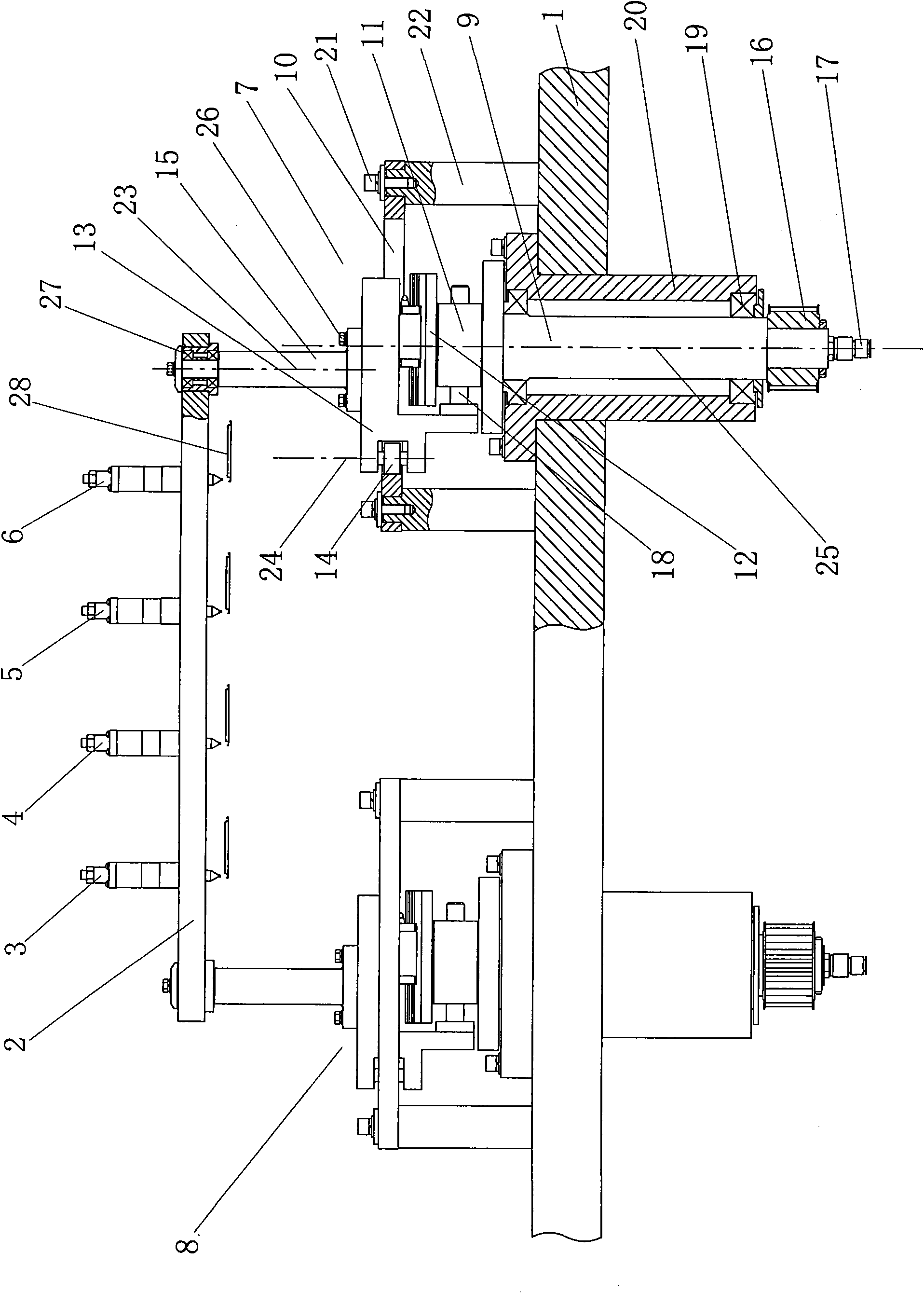

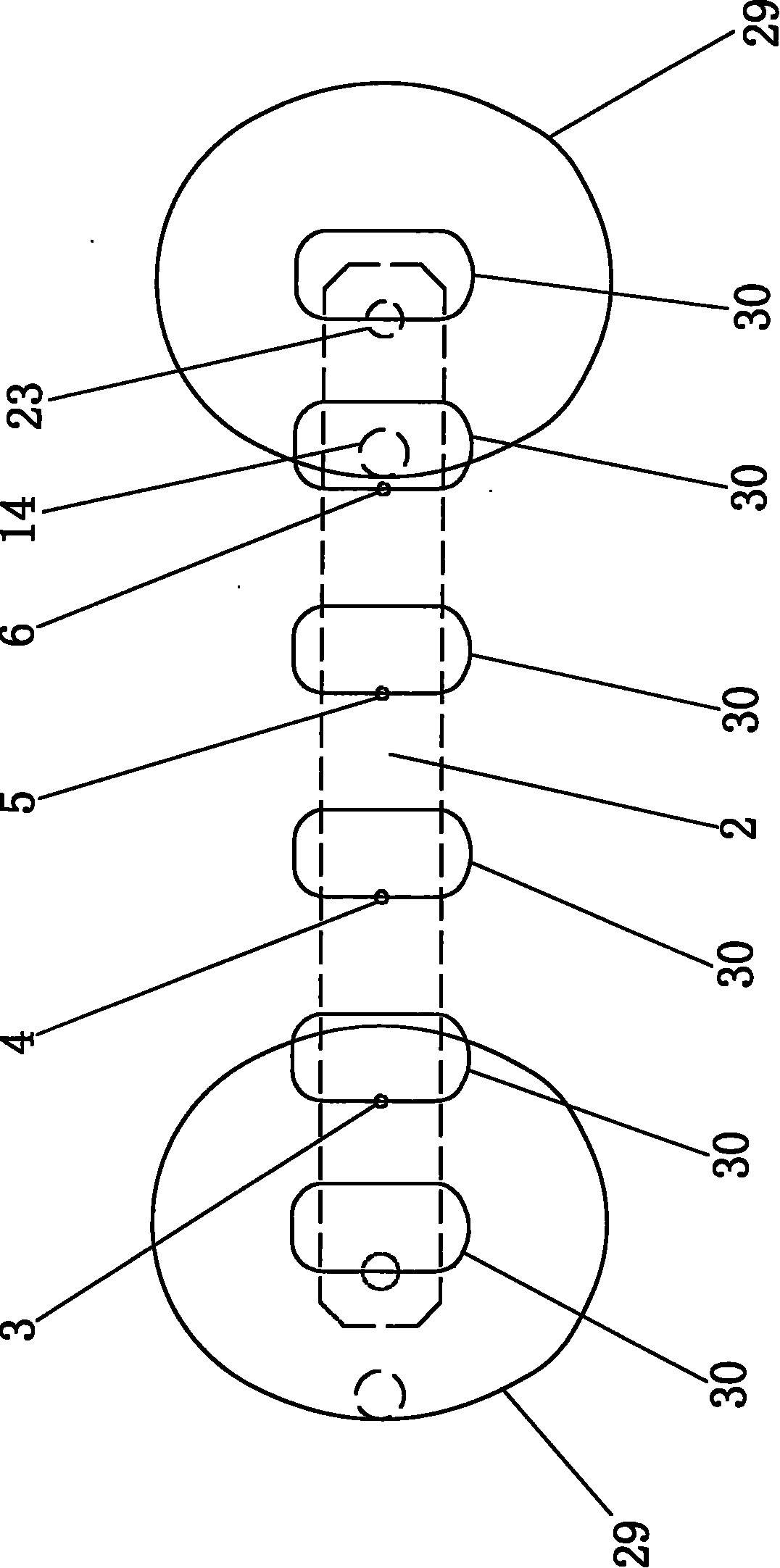

The invention discloses a multichannel high speed special metal cover gluing mechanism. The gluing mechanism is to solve the problems that in the prior art, one gluing device can only glue one special metal can cover once and has low working efficiency, components vibrate and shift so as to influence the precision of a glue injecting track, and uneven momentary linear speed of glue injecting headoperation causes uneven glue injecting thickness and unsuitability for high-speed operation. The technical proposal is characterized by comprising a stander, a translational plate on the stander, a plurality of gluing guns and a pair of translational plate track controlling mechanisms, wherein the plurality of the gluing guns are fixed on the translational plate respectively; each translational plate track controlling mechanism consists of a rotating shaft, an inner curve template, a cylinder, a sliding rail, a roller frame, a roller, a control rod, a transmission wheel, and an airpipe revolving joint; the cylinder, the sliding rail, the roller frame and the roller are positioned in the middle of the inner curve template; the roller is contacted with the inner curve template; the cylinderprovides the contact pressure for the roller and is communicated with an external pressure airpipe; the gluing guns are communicated with an external glue feeding pipe; and the transmission wheel is connected with a power driving wheel.

Description

A multi-channel high-speed special-shaped metal cover glue coating mechanism technical field The invention relates to a working mechanism on a sealant coating equipment for metal packaging cans, in particular to a multi-channel high-speed glue coating mechanism that can simultaneously inject glue or spray a layer of sealant on a plurality of special-shaped metal can lids at one time. Background technique Metal cans for packaging made of thin metal sheets are a category of packaging containers commonly used at present. Such metal cans are usually composed of a can body and a can lid joined to its upper and lower openings. The can body is bent from a thin metal sheet Afterwards, high-frequency resistance seam welding machine is used to weld the connecting seam to form, and the tank cover is formed by punching and bending the metal sheet. In order to ensure a good seal between the can lid and the can body after sealing, a layer of sealant is generally injected on the joint ed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05C9/00B05C11/00B05C13/02B05C21/00

Inventor 高泽毅李蓝翎

Owner 黄锐龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com