Oxidation resisting dipeptide medicament intercalated houghite and preparation method thereof

A technology for oxidizing dipeptide and hydrotalcite, which is applied in the direction of pharmaceutical formulations, drug combinations, dipeptide components, etc., to achieve good thermal stability and shorten crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

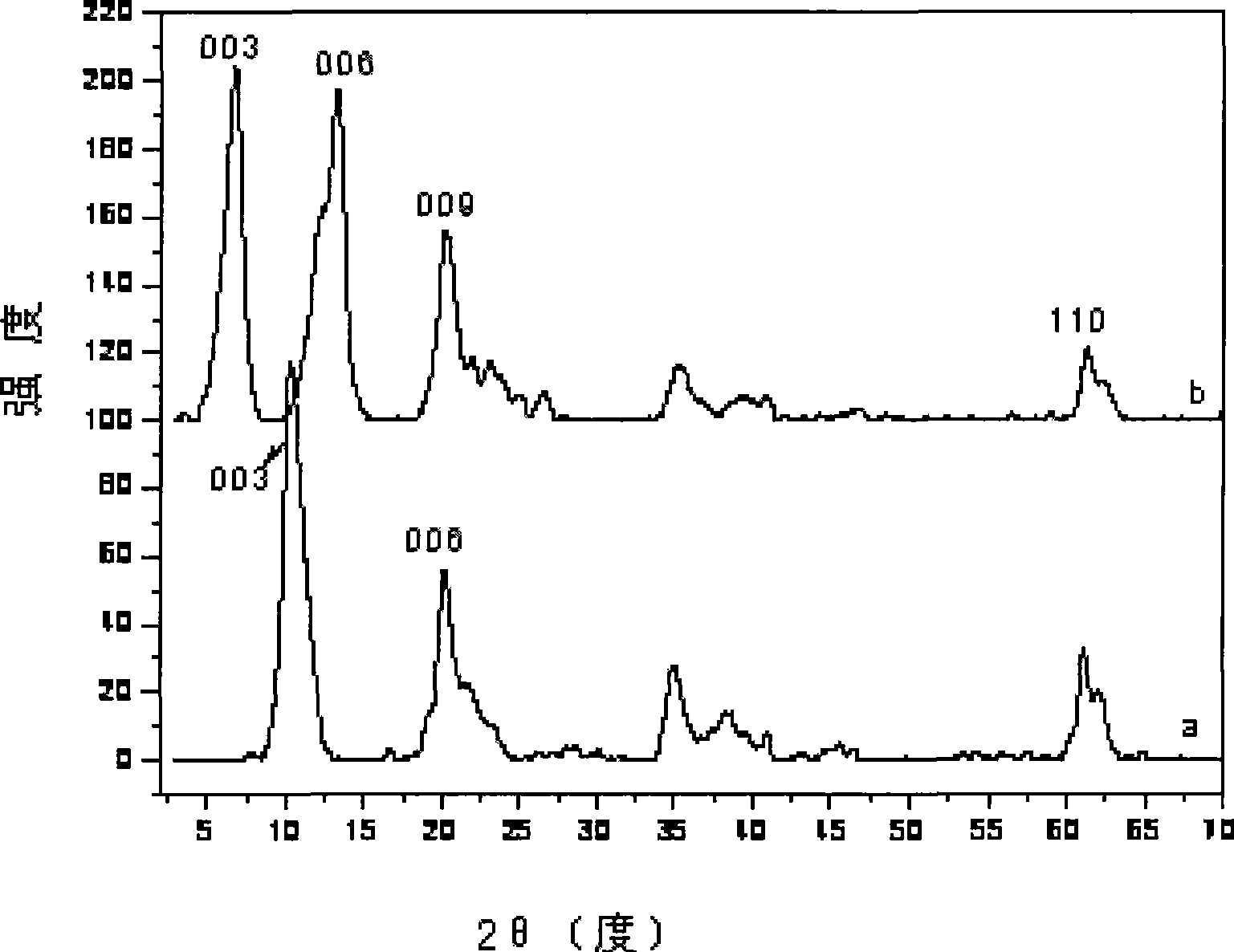

Image

Examples

Embodiment 1

[0027] A. Add 0.015mol of solid Mg(NO 3 ) 2 ·6H 2 O and 0.0075mol of solid Al(NO 3 ) 3 9H 2 O dissolved in 50mL to remove CO 2 Prepare a mixed salt solution of magnesium nitrate and aluminum nitrate in deionized water;

[0028] B. Dissolve 0.018mol carnosine and 0.0625mol NaOH in 50mL to remove CO 2 Prepare the mixed solution of carnosine and NaOH in deionized water;

[0029] C. Mix the nitrate solution prepared in step A under N 2 Slowly added dropwise to the mixed solution prepared in step B under protected conditions, stirred, and adjusted the pH range of the solution to 9 with 3mol / L NaOH;

[0030] D. Crystallizing the slurry obtained in step C at 60° C. for 24 hours;

[0031] E. The product is removed by CO 2 The deionized hot water was centrifuged and washed to neutrality, and dried at 70°C for 20 hours to obtain carnosine-intercalated hydrotalcite.

Embodiment 2

[0033] The slurry obtained in step C in Example 1 was transferred to a microwave rapid digestion tank, heated by microwave at 100° C. for 0.5 h, and the obtained product was used to remove CO 2 The deionized hot water was centrifuged and washed to neutral, and dried at 70°C for 24 hours to obtain carnosine-intercalated hydrotalcite.

Embodiment 3

[0035] Step A: take by weighing 15.384g Mg(NO 3 ) 2 ·6H 2 O and 11.2539g Al(NO 3 ) 3 9H 2 O dissolved in 100ml to remove CO 2 1. Prepare mixed salt solution with deionized water;

[0036] Step B: Dissolve another 7.2g NaOH in 100ml to remove CO 2 , deionized water;

[0037] Step C: Mix the nitrate solution prepared in step A under N 2 Slowly add dropwise to the lye prepared in step B under protected conditions, stir, adjust the pH range of the solution to 10 with 3mol / L NaOH, crystallize at 70°C for 40 hours, and remove CO 2 The deionized hot water is centrifugally washed to neutrality to obtain the nitrate hydrotalcite precursor;

[0038] Step D: dissolving carnosine in water, adding undried nitrate hydrotalcite precursor, the molar ratio of carnosine to aluminum ion is 1-3, and adjusting the pH to 8;

[0039] Step E: In 60 °C water bath and N 2 Ion exchange under protected conditions for 24 hours, the obtained product was used to remove CO 2 1. Centrifugal washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com