Integral type water cooling bottom part ring of combination holder of closed submerged arc furnace and process for producing same

An integral, submerged arc furnace technology, applied in the direction of electric heating devices, heating by discharge, electrical components, etc., can solve the negative impact of production cost, output and quality, operation control of submerged arc furnace and adverse effects of furnace conditions, electrode cylinder To improve the comprehensive efficiency and output rate, avoid the phenomenon of water leakage and stinging, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

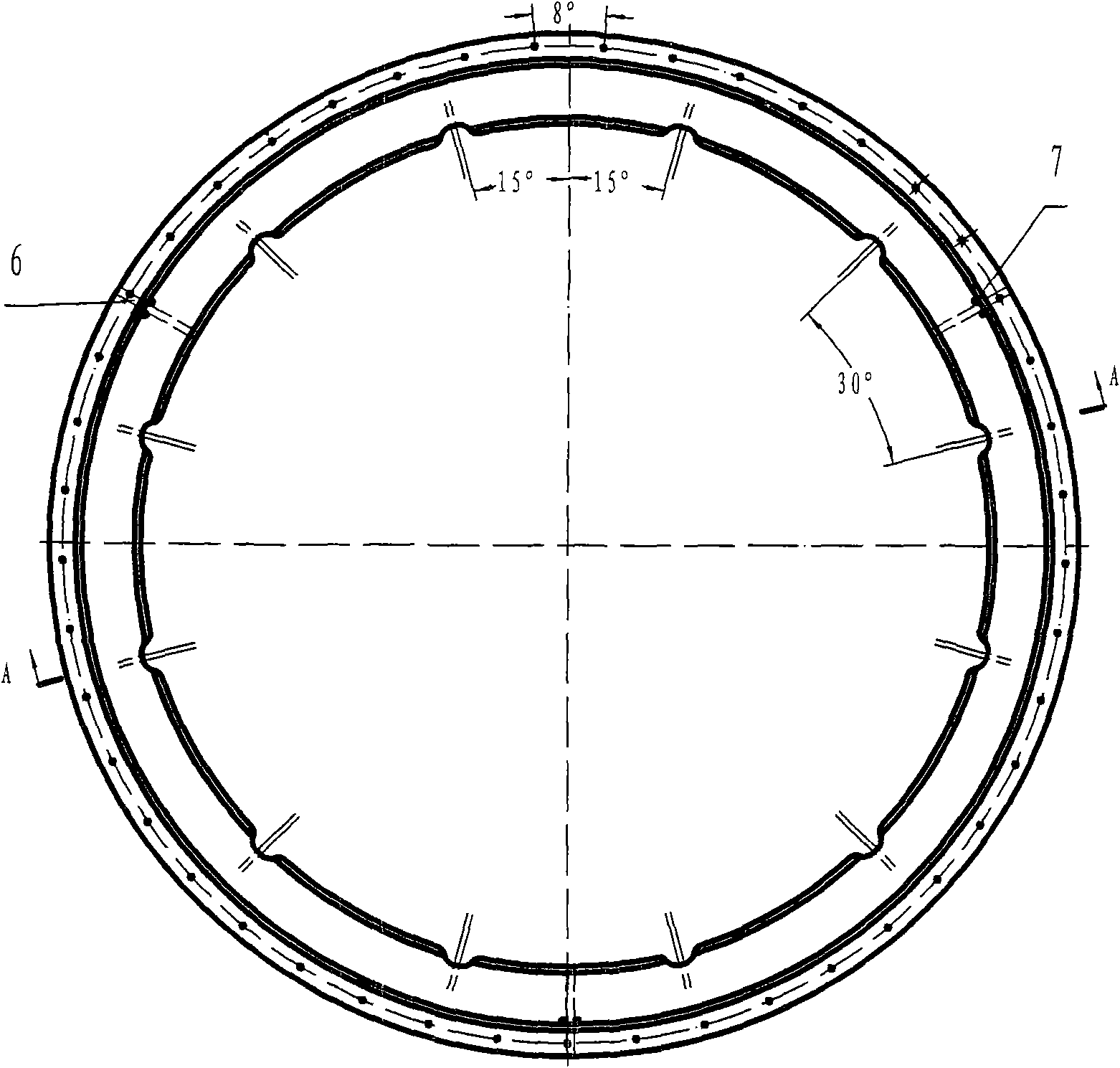

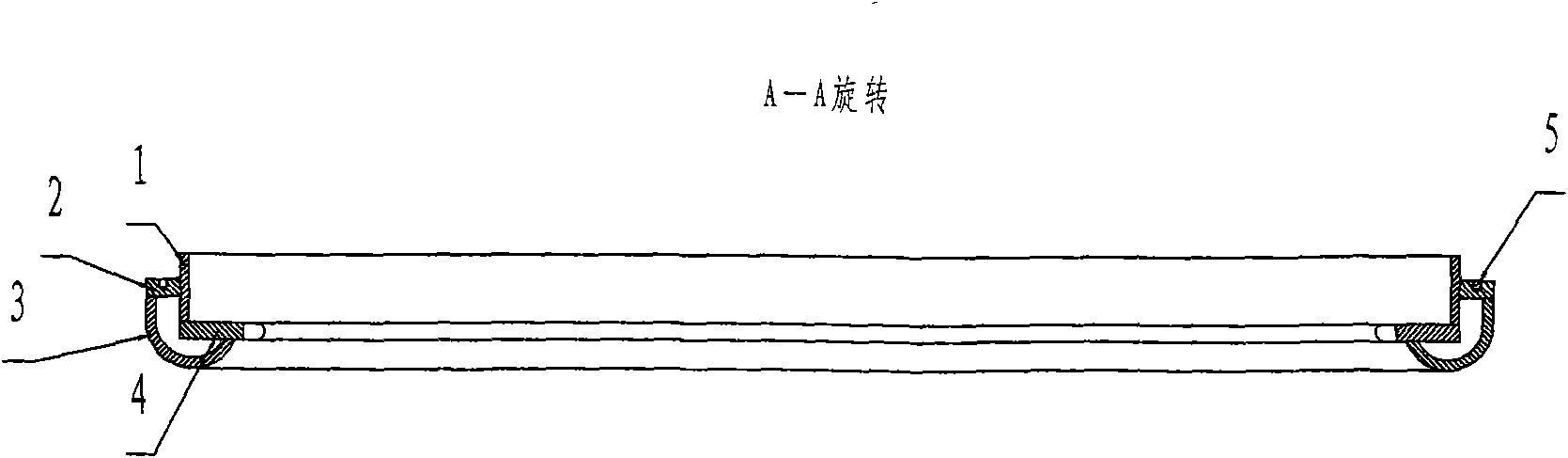

[0013] Such as figure 1 , 2 As shown, the integral water-cooled bottom ring of the present invention is made of stainless steel, which is mainly composed of an inner stainless steel ring plate 1, a water-cooling protective cover insulation plate is installed with a stainless steel ring plate 2, and a thick-walled stainless steel pipe is rolled into a ring and cut into pieces. Formed semi-circular body 3, contact element protection support stainless steel ring plate 4, stainless steel partition 6 welded and fabricated.

[0014] The production process is to first make the semi-circular body 3 formed by rolling thick-walled stainless steel pipe into a ring and cut it into shape, and then install the insulating plate of the water-cooling protective sleeve with the stainless steel ring plate 2 and the semi-circular body 3 in multiple points. Welding, and the welding is firm, then the contact element protection support stainless steel ring plate 4 is welded to the semi-circular bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com