Hydrostatic drive with braking energy recovery feature

A kind of transmission device and hydrostatic technology, which is applied in the direction of transmission device control, power device, pneumatic power device, etc., and can solve the problem that the device cannot be converted to a driving transmission device with an open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

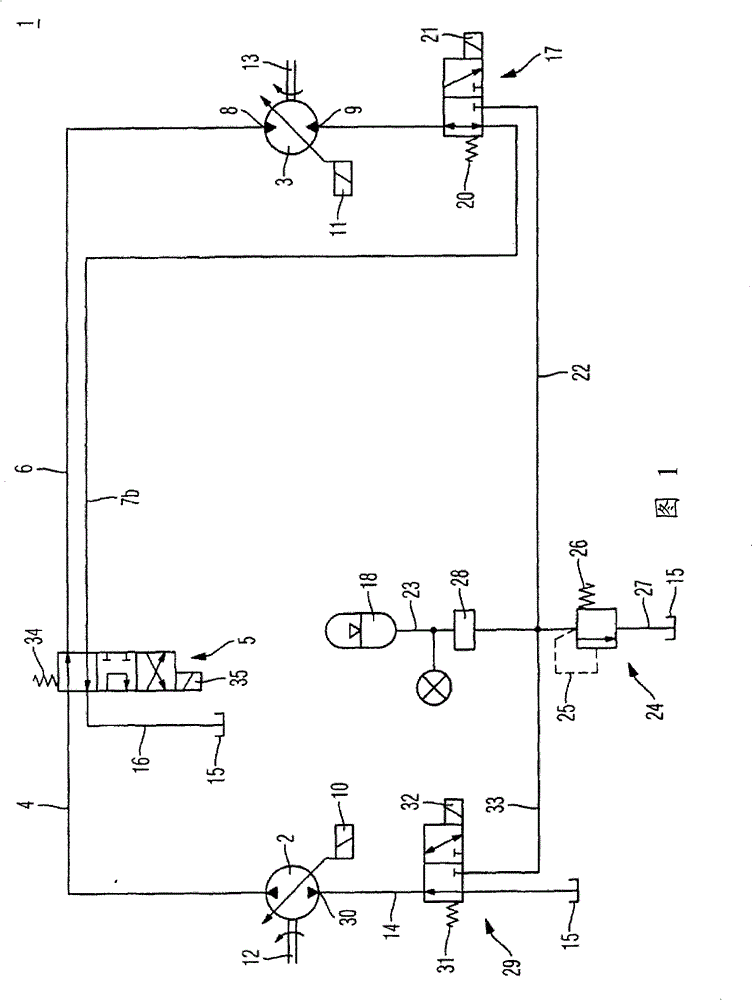

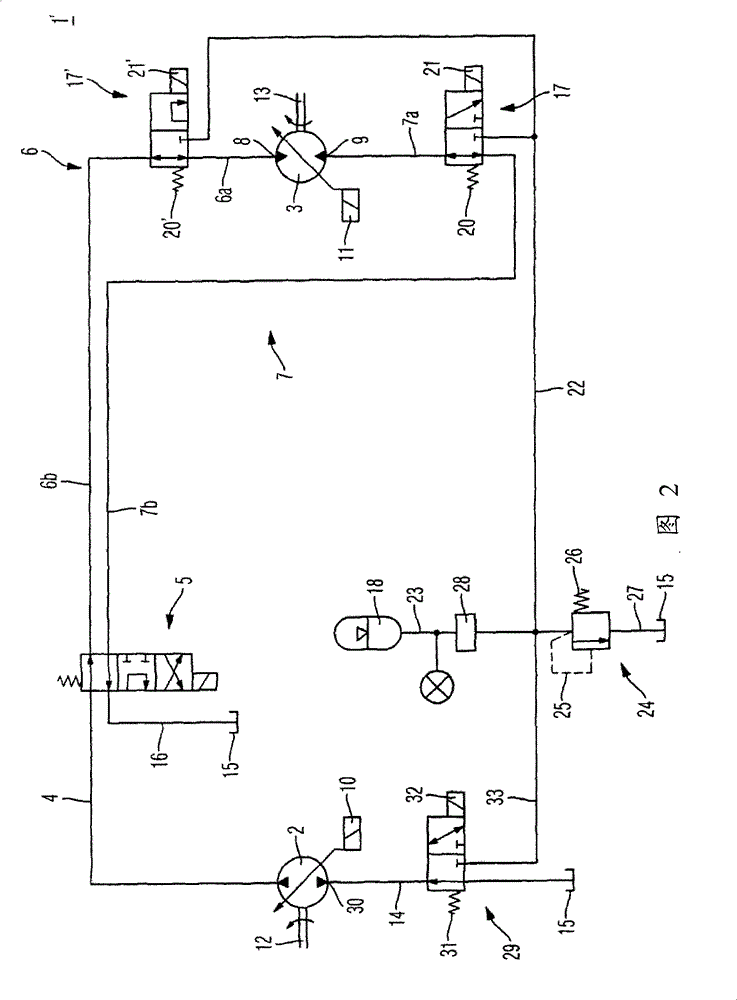

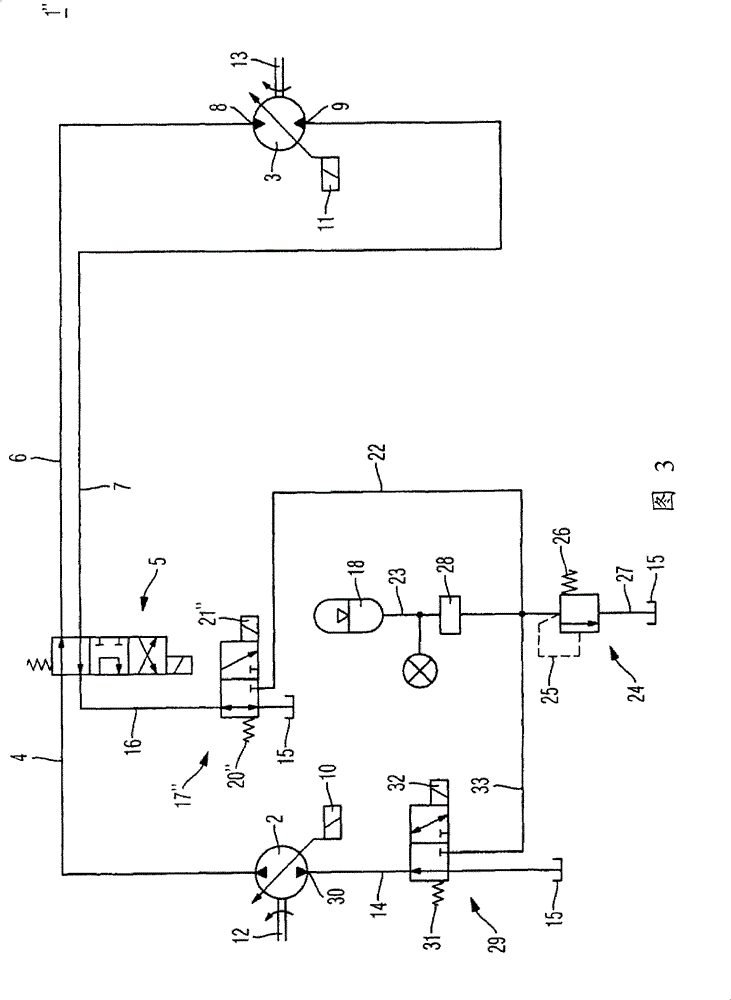

[0021] figure 1 A hydraulic circuit diagram of a first exemplary embodiment of a hydrostatic transmission according to the invention is shown. A hydrostatic transmission is a vehicle-driven traction transmission 1 by means of a hydrostatic transmission. Such a vehicle could be, for example, a wheel loader, stacker or refuse truck. Such vehicles are subject to particularly intensive drive cycles, in which acceleration and braking are repeated frequently, often one after the other. Therefore, the recovery of energy released during the braking process is of particular concern for these three types of vehicles.

[0022] The travel transmission 1 includes a hydraulic pump 2 and a hydraulic motor 3 . The hydraulic pump 2 and the hydraulic motor 3 are arranged in an open hydraulic circuit. The hydraulic pump 2 delivers pressure medium to a transfer line 4 which is connected at its transfer-side connection to the hydraulic motor 3 . The transfer line 4 is connected to a first hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com