Method for preparing transparent nano imprinting template based on X-ray exposure technology

A nano-imprinting and X-ray technology, applied in optics, opto-mechanical equipment, photosensitive material processing, etc., can solve the problem of engraving high-resolution graphics, etc., and achieve the effect of convenient alignment means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

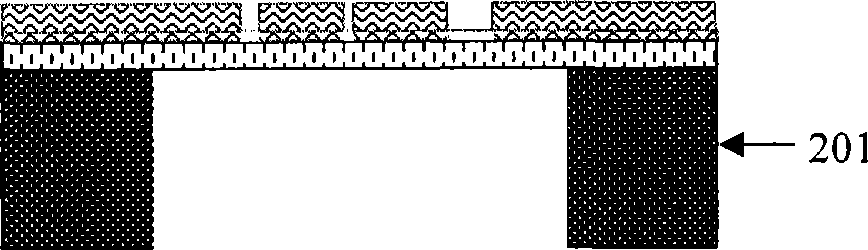

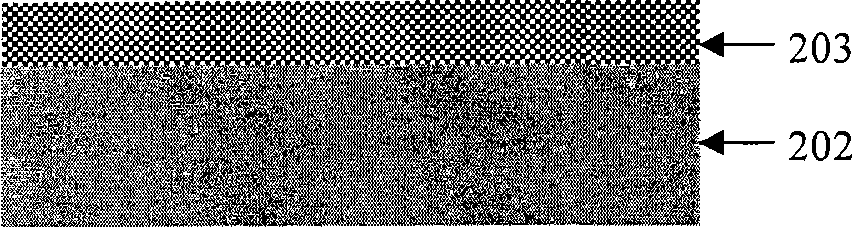

[0028] The method for making a transparent nano-imprint template provided by the present invention, the transparent nano-imprint template is made of a nano-X-ray exposure template by electron beam lithography, and the nano-pattern is transferred to a non-conductive quartz as a substrate through X-ray exposure. On the bottom of the photoresist, after development, the metal nano-pattern on the quartz substrate is obtained by evaporating metal and stripping process, using the metal as a barrier layer and using reactive ion etching on the quartz to obtain the nano-pattern on the quartz, removing the metal to complete light transmission Fabrication of nanoimprint templates.

[0029] like figure 1 as shown, figure 1 It is a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com