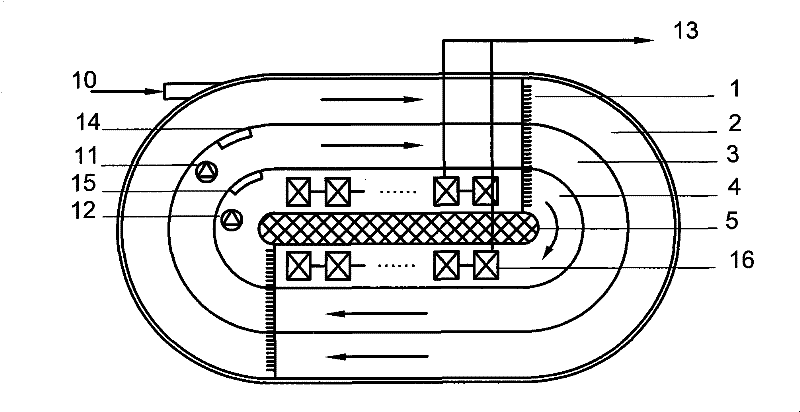

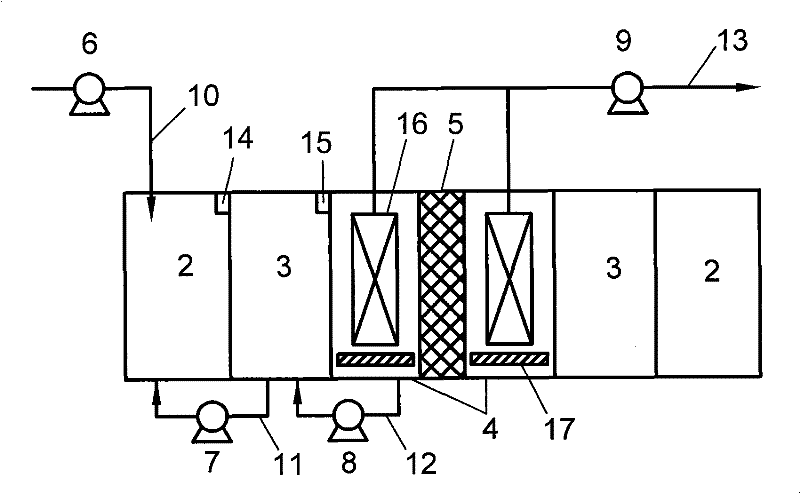

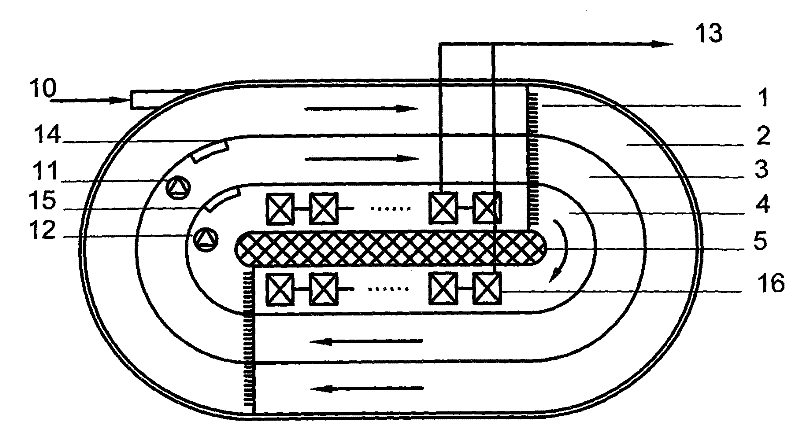

High-efficient denitrification and dephosphorization MBR process and device

A high-efficiency technology for nitrogen and phosphorus removal, applied in the field of sewage treatment process for nitrogen and phosphorus removal, can solve the problems of unreachable phosphorus content in effluent, poor sludge settling performance, and large floor area, so as to improve nitrification and denitrification effect, promotion of enrichment, and effect of increasing sludge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: The sewage water quality condition is: COD Cr The content is 300 to 500 mg / L, the total nitrogen content is 30 to 50 mg / L, and the total phosphorus content is 7 to 10 mg / L. The mixed liquid reflux ratio of 1# mixed liquid return pipe is 200%, the mixed liquid reflux ratio of 2# mixed liquid return pipe is 200%, the sludge concentration is 5g / L, and the hydraulic retention time is 24h. Final effluent COD Cr Less than 50mg / L, total nitrogen less than 10mg / L, total phosphorus less than 0.5mg / L, meeting the national landscape environmental water standards.

example 2

[0024] Example 2: The sewage water quality condition is: COD Cr The content is 300 to 500 mg / L, and the total nitrogen content is 30 to 50 mg / L. The mixed liquid reflux ratio of 1# mixed liquid return pipe is 200%, the mixed liquid reflux ratio of 2# mixed liquid return pipe is 200%, the sludge concentration is 5g / L, and the hydraulic retention time is 18h. Final effluent CODCr Less than 50mg / L, total nitrogen less than 12mg / L, total phosphorus less than 0.5mg / L, meeting the national landscape environmental water standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com