Method and device for preparing basic magnesium hypochlorite by using waste chlorine

A technology of magnesium hypochlorite and sodium hypochlorite, which is applied to the equipment for preparing basic magnesium hypochlorite, the preparation of basic magnesium hypochlorite, and the field of production of basic magnesium hypochlorite, which can solve the problems of low yield and achieve the goal of preparing Simple process, stable properties, mild oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

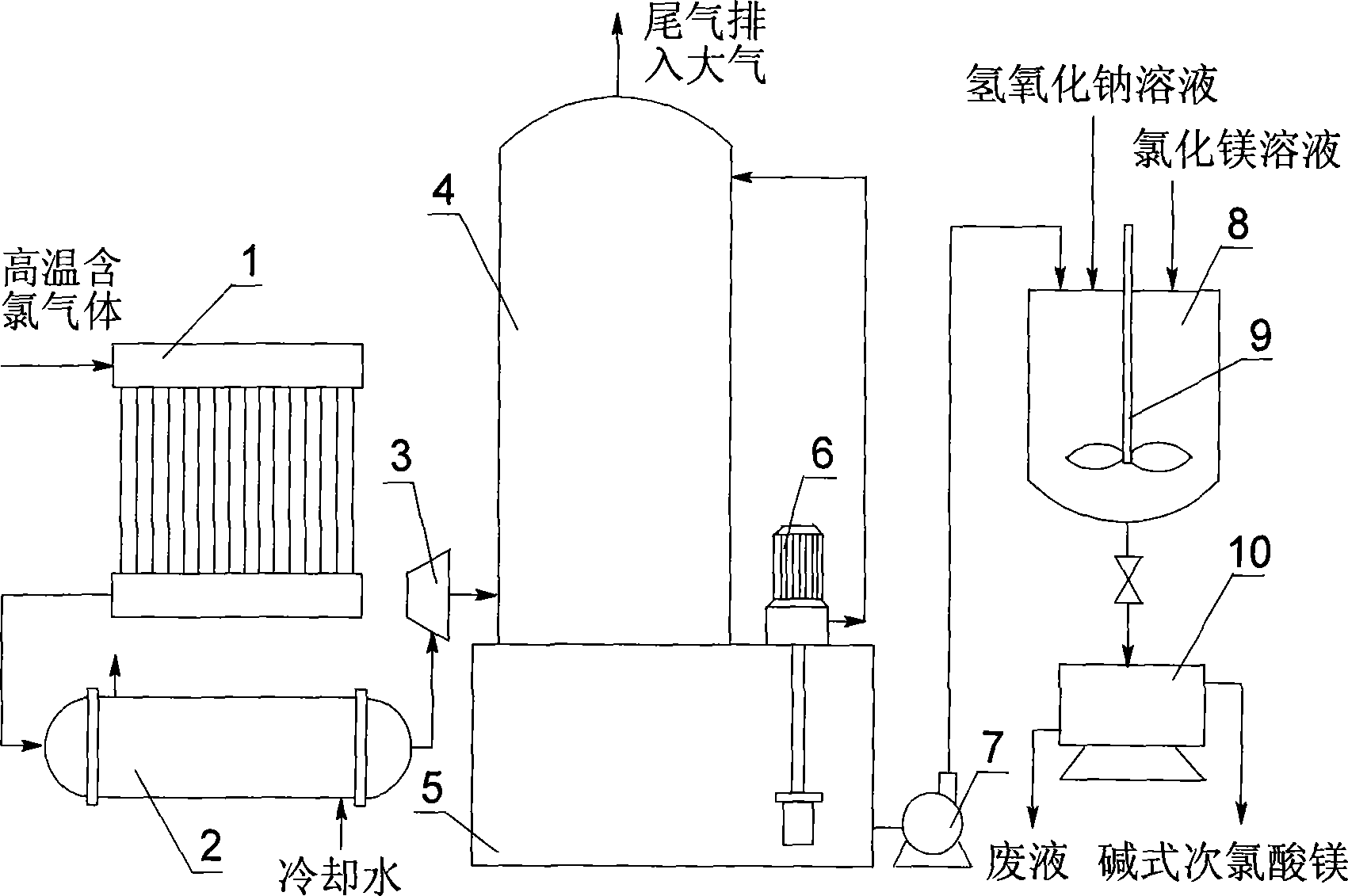

[0033] Embodiment 1: utilize the chlorine-containing gas produced in the process of preparing rare earth metal by electrolysis of chloride system molten salt to prepare basic magnesium hypochlorite equipment and technology as follows:

[0034] (1) Equipment

[0035] The present invention prepares the equipment of basic magnesium hypochlorite, comprises air heat exchanger 1, water cooler 2, absorption tower 4, liquid storage tank 5, reactor 8 and centrifuge 10 successively, wherein heat exchanger 1 is connected by pipeline The water cooler 2 is connected to the bottom of the absorption tower 4 through the pipeline and the fan 3; the liquid storage tank 5 is arranged on one side of the absorption tower 4, and the upper part of the liquid storage tank 5 is connected to the liquid absorption tower through the submerged pump 6 and the pipeline. The top of 4 is connected, and the lower part of the liquid storage tank 5 is connected with the reactor 8 through the liquid delivery pump...

Embodiment 2

[0044] Example 2: Using anhydrous magnesium chloride and rare earth chloride as the main raw materials to electrolyze the chlorine-containing gas produced in the process of preparing the rare earth magnesium master alloy to prepare basic magnesium hypochlorite

[0045] (1) Equipment

[0046] Basically the same as embodiment 1, the difference is that two lye absorption towers 4 need to be arranged to ensure that the chlorine content in the tail gas discharged from the top of the absorption tower reaches the discharge standard. When using two or more lye absorption towers, the top of the previous lye absorption tower is connected with the bottom of the next lye absorption tower through a pipeline.

[0047] (2) Process

[0048] In the process of preparing rare earth magnesium master alloy by electrolysis using anhydrous magnesium chloride and rare earth chloride as main raw materials, the electrolysis current is 2000-4000A, the electrolysis temperature is 800-900°C, and 3-6kg of...

Embodiment 3

[0054] Example 3: Preparation of basic magnesium hypochlorite by using partially dehydrated magnesium chloride and partially dehydrated rare earth chloride as the main raw materials to electrolytically prepare the chlorine-containing gas produced in the process of preparing the rare earth magnesium master alloy

[0055] The electrolysis current is 2000-4000A, the electrolysis temperature is 800-900°C, and 3-6kg of chlorine gas is produced per hour.

[0056] The preparation device and the preparation process are the same as in Example 2.

[0057] The available chlorine content in this product is 38.3%, the magnesium content is 29.6%, and the available chlorine yield is 86.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com