Transonic speed controllable vortex gas dehumidifier

A transonic and gas technology, applied in the field of transonic controllable vortex gas dehumidification device, can solve the problems of large total pressure loss and low dehumidification and separation efficiency, and achieve improved back pressure efficiency, improved dehumidification and separation efficiency, and better aerodynamic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

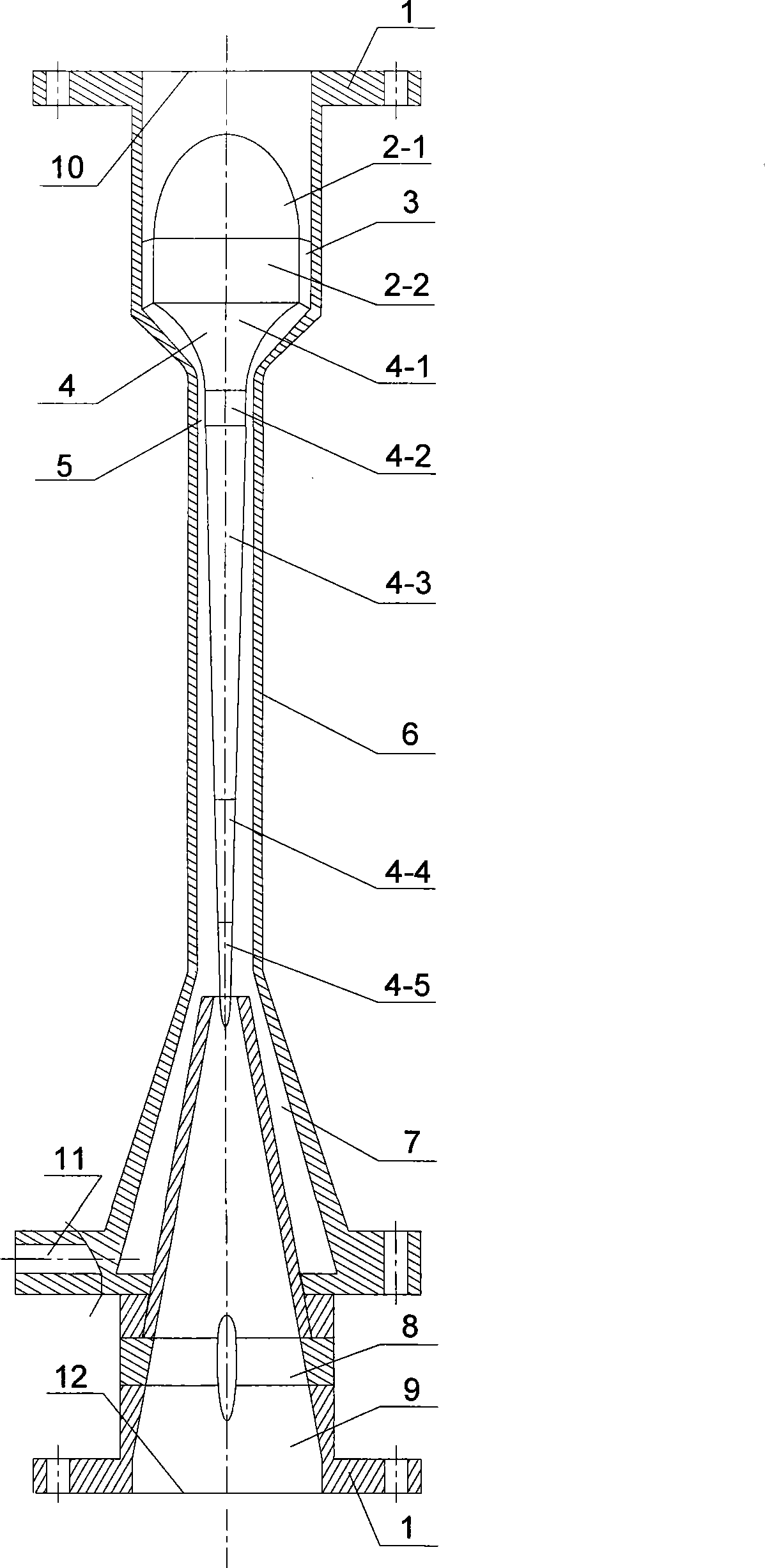

[0027] Taking a transonic controllable vortex gas dehumidification device with a daily processing capacity of 400,000 standard cubic meters of natural gas as an example, the structure and working principle of the present invention will be further described in detail below.

[0028] refer to figure 1 . The transonic controllable vortex gas dehumidification device of the present invention comprises a housing 6 with an airflow inlet 10 on the upper end, a liquid discharge port 11 and an exhaust port 12 on the lower end, a connecting flange 1 is arranged on the upper end of the housing, and the inner diameter of the housing 6 is 20mm.

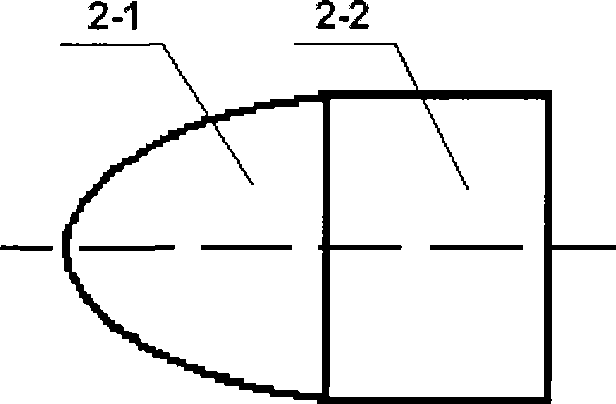

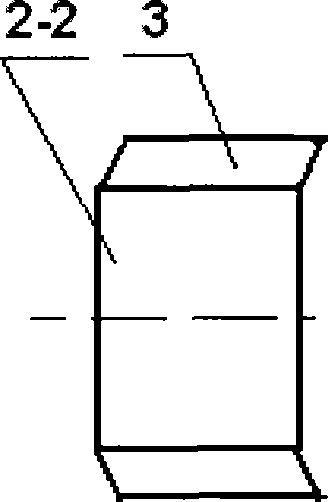

[0029]The shell 6 is composed of an inlet pipe 6-1, a conical reducer 6-2, a straight pipe 6-3 and a conical expander 6-4, and a blunt body rectifier 2 is fixed inside the inlet pipe 6-1. The rectifier 2 is composed of an ellipsoidal head 2-1 and a cylindrical base 2-2, and a vortex generator 3 composed of stationary vanes is fixed around the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com