Bend pipe and process for producing the same

A manufacturing method and pipe bending technology, which is applied in the direction of manufacturing tools, tubular objects, and other household appliances, etc., can solve problems such as difficulty in being used in pipelines, low tensile strength, and increased content of alloy elements, and achieve the reduction of strength and toughness. , Yield strength reduction suppression, yield strength reduction improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] The present invention is described more specifically with reference to the examples.

[0115] A base metal having the composition, carbon equivalent Ceq, and weld crack sensitivity index Pcm shown in Table 4, and a UOE steel pipe having a weld metal with the weld crack sensitivity index Pcm, B amount, and O amount shown in Table 4, It heated to the heating temperature shown in Table 4, and performed bending processing. In addition, the welding of UOE steel pipes is carried out by longitudinal seam welding using a high-basicity flux having the basicity shown in Table 4 and not containing boron.

[0116]

[0117]

[0118] Immediately after bending, the steel pipes were cooled to a temperature range of 300° C. or lower at the cooling rate shown in Table 4, and then tempered at the tempering temperature shown in Table 4 to manufacture bent pipes.

[0119] The "cooling rate" in Table 4 indicates the cooling rate at the central portion of the tube in the thickness dire...

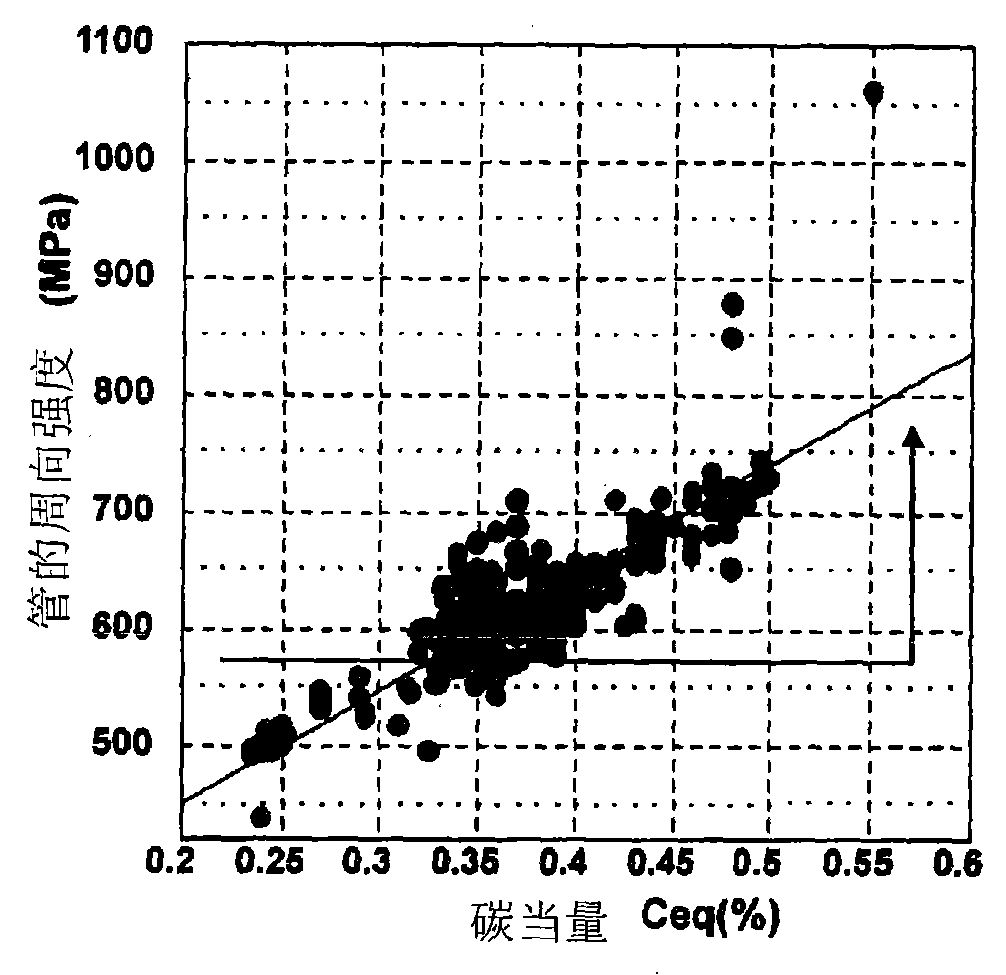

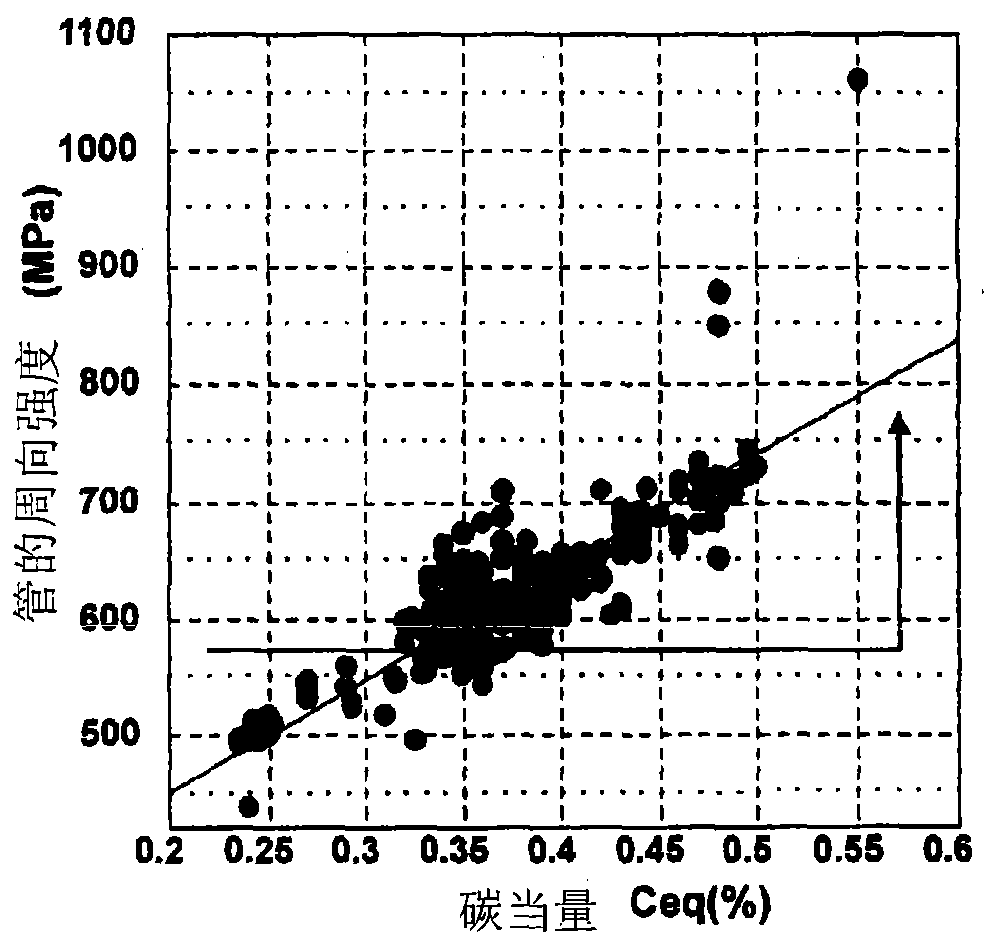

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon equivalent | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com