Tactile sensor for curved surfaces and manufacturing method thereof

A tactile sensor, curved surface technology, applied in the tactile field, can solve problems such as difficulty and lack of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

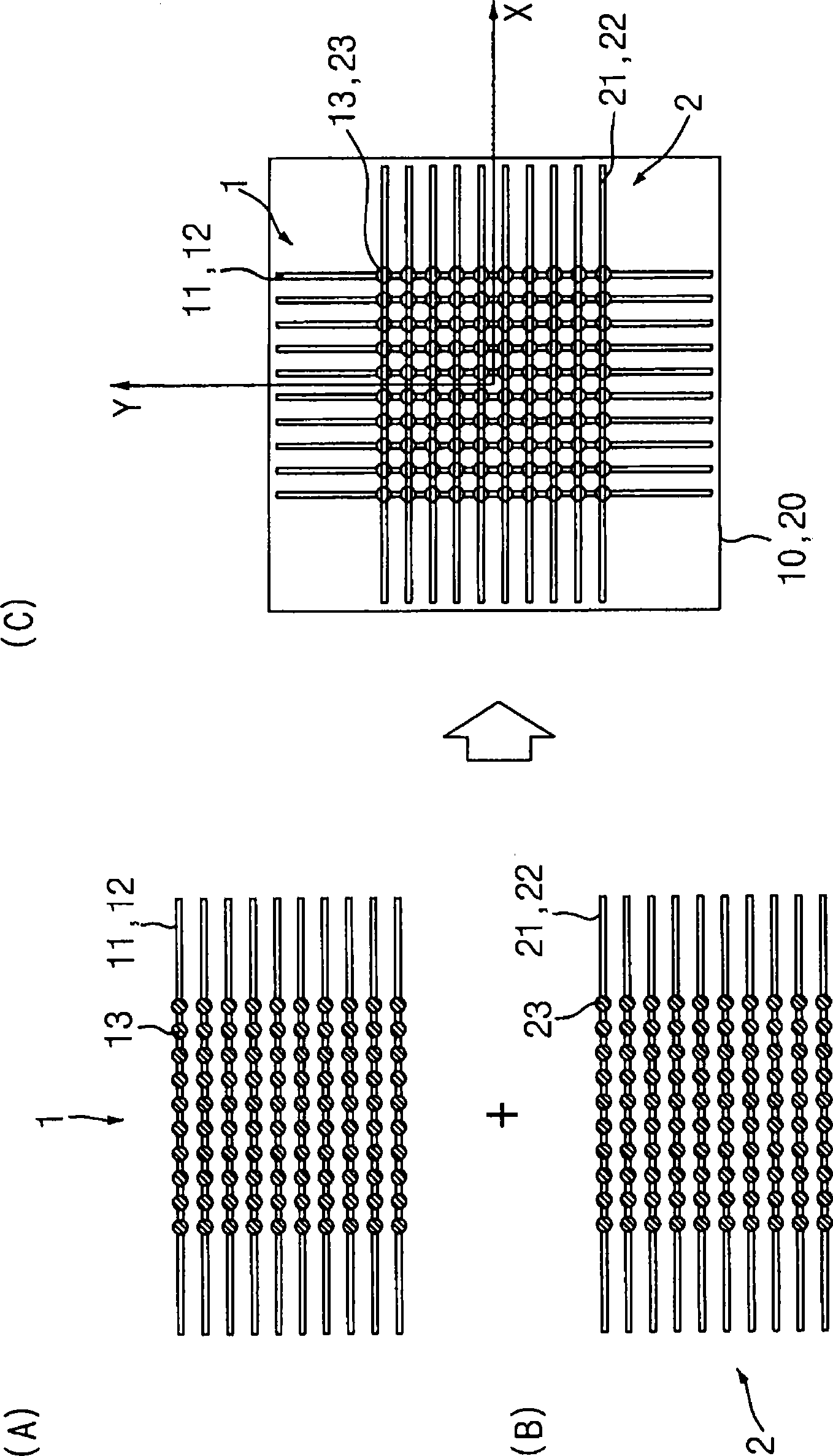

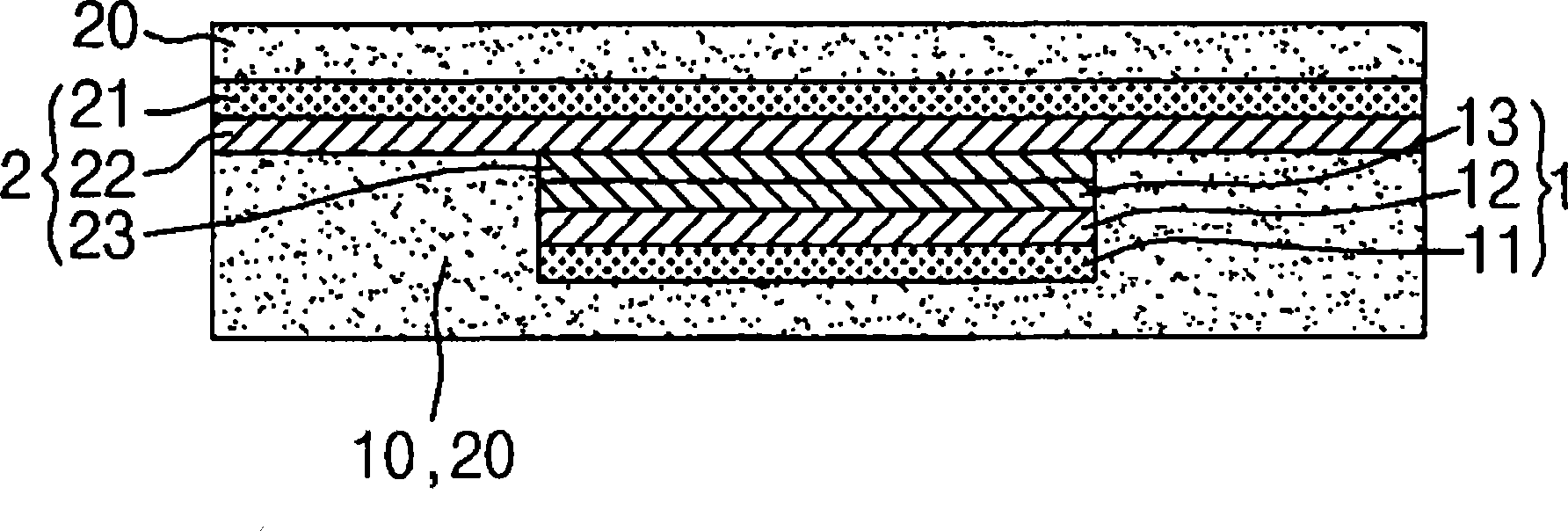

[0029] figure 1 (A), (B) and (C) represent plan views of a tactile sensor for a curved surface according to a lower embodiment of the present invention. figure 2 express figure 1 (C) shows the cross-sectional view of the tactile sensor for curved surfaces.

[0030] see figure 1 (A), (B) and (C), figure 1 (A) shows a plan view of the underlying pattern of the tactile sensor. figure 1 (B) shows a plan view of the backside of the upper layer pattern of the tactile sensor. figure 1 (C) shows a plan view of a touch sensor obtained by combining the lower layer pattern and the upper layer pattern. According to an embodiment of the present invention, the touch sensor for a curved surface includes a lower pattern 1 and an upper pattern 2 having a lower polymer film layer 11 and an upper polymer film layer 21 respectively.

[0031] In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com