High performance liquid chromatography analysis method for oxalic aldehyde and glyoxalic acid

A high-performance liquid chromatography, glyoxal technology, applied in the direction of analysis of materials, material separation, measurement devices, etc., can solve the problems of time-consuming detection, easy to interfere with results, difficult to quantify, etc., to achieve a high degree of automation, tedious compensation process, Detect sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

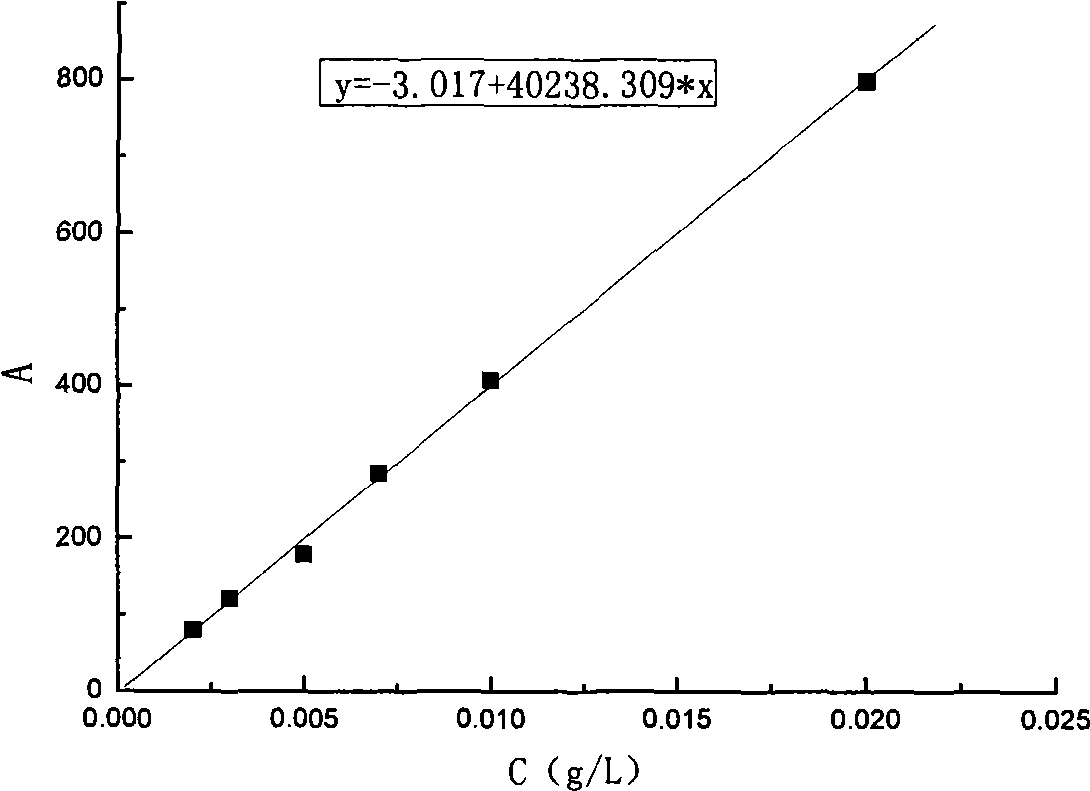

[0043] A. Drawing of glyoxal standard curve

[0044]a), preparation of glyoxal standard solution: take 1mL of 40wt% glyoxal solution, in a 50mL volumetric flask, use deionized water to constant volume to obtain a 10g / L glyoxal solution, pipette 1mL in a 100mL volumetric flask To get 0.1g / L glyoxal solution, pipette 1, 1.5, 2.5, 3.5, 5, 10mL respectively into 50mL volumetric flask, and make 0.002, 0.003, 0.005, 0.007, 0.01, 0.02g / L glyoxal Aldehyde standard sample solution;

[0045] b) Preparation of glyoxal-DNPH derivative samples: take 0.002, 0.003, 0.005, 0.007, 0.01, 0.02g / L glyoxal standard sample solution 1mL respectively, add 10mL0.2g / LDNPH solution (dissolved in acetonitrile) , using 5% phosphoric acid solution to adjust the pH to 2, reacting in a constant temperature water bath at 60°C for 120 minutes to obtain glyoxal-DNPH derivatives with different concentrations;

[0046] c) Agilent 1100 high-performance liquid chromatograph is used as an analyzer, equipped with a...

Embodiment 2

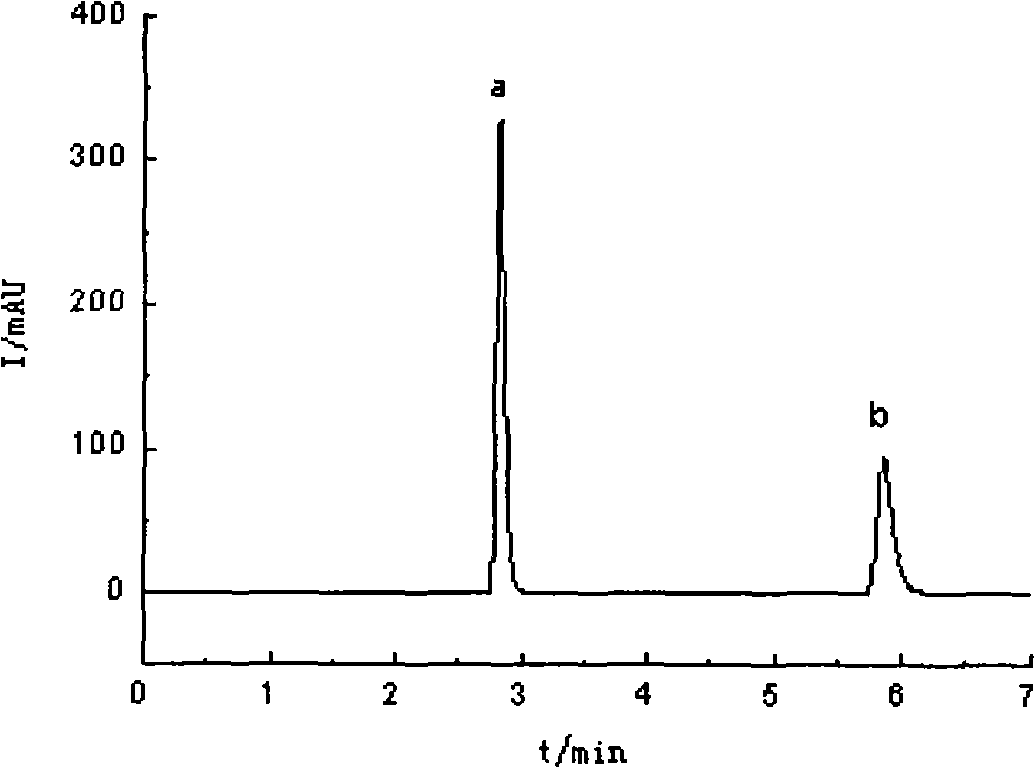

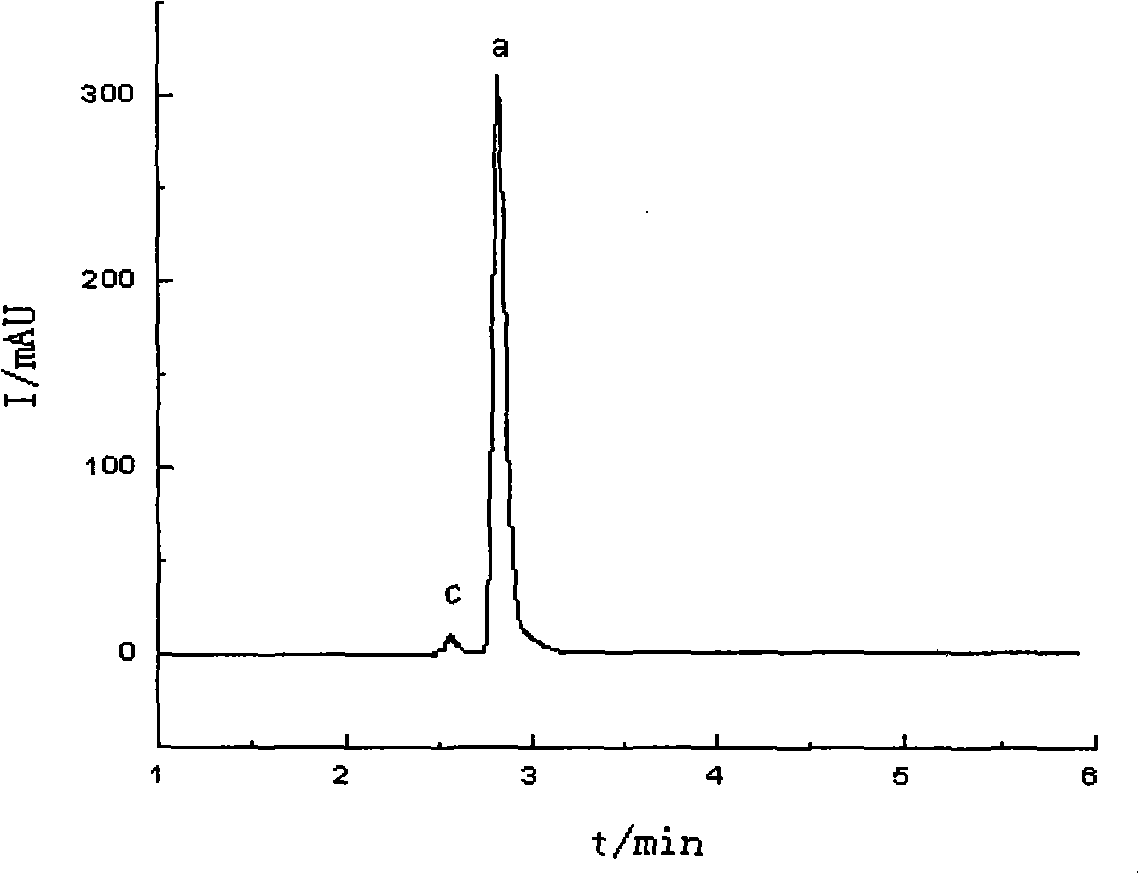

[0055] Use this method to detect the mixed reaction product solution of glyoxal by oxidation of acetaldehyde: dilute the reaction solution 10000 times, take 1mL diluted sample, add 10mL 0.2g / LDNPH solution (dissolved in acetonitrile), and adjust the pH with 5% phosphoric acid solution After reaching 2, react for 120 minutes in a constant temperature water bath at 60°C. The result is as Figure 4 shown. The abscissa in the figure is the retention time / min, and the ordinate is the absorbance / mAU. From Figure 4 It can be seen that two peaks a and b appear at the corresponding retention times of DNPH and glyoxal dihydrazone, and the separation of the peaks is very good. In addition, there are no other peaks, indicating that the content of glyoxylic acid and acetaldehyde is very low, even lower than the detection limit, and the by-products acetic acid and oxalic acid do not interfere with the detection of glyoxal dihydrazone. Substitute the peak area of glyoxal dihydrazone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com