Immobilized penicillin acylated enzyme with silicon gel rubber as carrier and preparation method

A technology of penicillin acylase and silica gel, which is applied in the direction of immobilization on or in the inorganic carrier, which can solve the problems of high price, difficult handling of polymer carriers, and high cost of immobilized enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Dissolve 20ml of silica sol with a mass fraction of 30% in 20ml of ethanol, stir and dissolve evenly, add 23ml of silane coupling agent γ-aminopropyltriethoxysilane (APTES) dropwise into the above solution at room temperature, Stop stirring, let the gel stand for 3 hours, use mechanical agitation to crush the agglomerates, add 20ml ethanol to rinse, and centrifuge, the product is rinsed with a large amount of distilled water, centrifuged, and the carrier (N-SG) used for immobilization is obtained. Store at 4-7°C under state. (Dry carrier specific surface area: 378m2 / g, average pore diameter 17nm)

[0034]2. Add 1 g of the above-mentioned wet carrier to 20 ml of glutaraldehyde solution with a mass fraction of 0.5%, stir at room temperature for 4 hours, centrifuge, rinse with 20 ml of distilled water for 3 times, and obtain the activated carrier (GA-SG) wet 3. Add 0.5g of the activated carrier to 15ml of phosphate buffer solution (0.2M) with pH 7.9, add 900μl of penic...

Embodiment 2

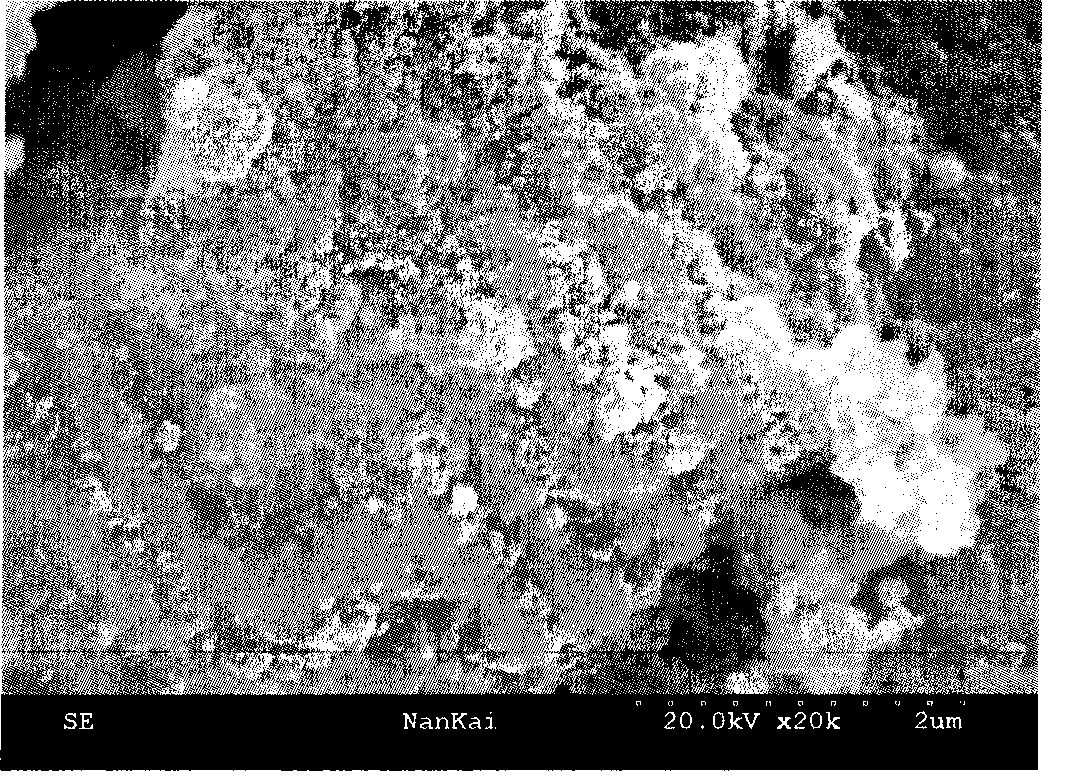

[0036] 1. Same as Example 1, the resulting product was freeze-dried, then vacuum-dried at 100° C. for 3 hours, and subjected to electron microscopy and surface adsorption tests. The specific surface area of the product measured is 320m / g, and the aperture is 17nm, and the electron microscope SEM figure is (a) among accompanying drawing 1.

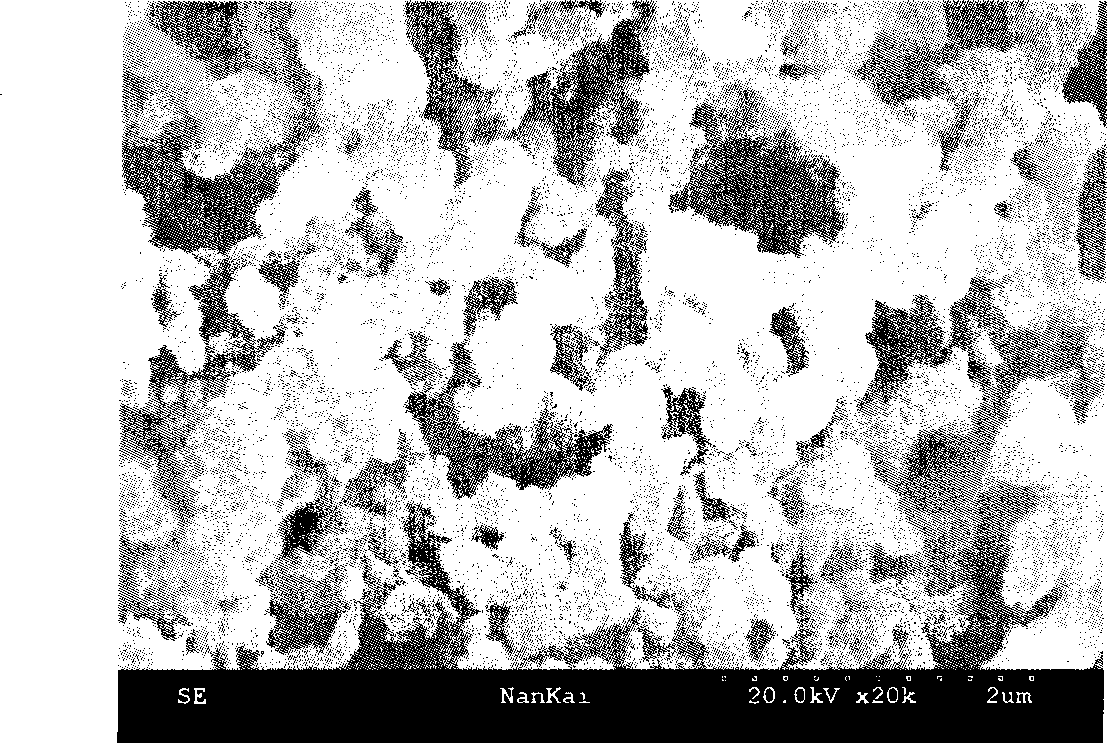

[0037] 2. Rinse 1 g of the wet carrier obtained in the above step 1 with 20 ml of acetone, then add 20 ml of 0.6% N, N-carbonyldiimidazole (CDI) in acetone solution, stir at room temperature for 4 hours, and centrifuge Separation, rinsed 3 times with 10ml acetone, and the activated carrier (CDI-SG) obtained was suspended in acetone and stored at 4-7°C. The obtained product was treated in the same way as in step 1 to obtain a specific surface area of 246m2 / g and a pore size of 24nm. Electron microscopy The SEM image is (b) in Figure 1.

[0038] 3. Rinse 0.5g of the carrier activated in step 2 with 10ml of pH7.9 phosphate buffer solution...

Embodiment 3

[0046] 1. Dissolve 20ml of silica sol with a mass fraction of 30% in 20ml of ethanol, stir and dissolve evenly, and drop 30ml of silane coupling agent γ-(2,3-glycidyloxy)propyltrimethoxysilane at room temperature Add it into the above solution, stop stirring, let the gel stand for 3 hours, break up the agglomerates with mechanical stirring, add 20ml of ethanol to rinse, and centrifuge, the product is rinsed with a large amount of distilled water, centrifuged to obtain a carrier for immobilization, wet Stored at 7°C in a cold state.

[0047] 2. Add 1 g of the above-mentioned wet carrier to 20 ml of 1,4-diglycidyl ether solution with a mass fraction of 1.0%, stir at room temperature for 24 hours, centrifuge, rinse with 20 ml of distilled water for 3 times, and obtain the activated carrier wet Store at 4-7°C under state

[0048] 3. Add 0.5g of the activated carrier to 15ml, pH8.1 phosphate buffer solution (0.25M), add 2000μl penicillin acylase enzyme solution, stir slowly at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com