Core-three-circulation combined water treatment process

A water treatment, three-cycle technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Low, small footprint, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

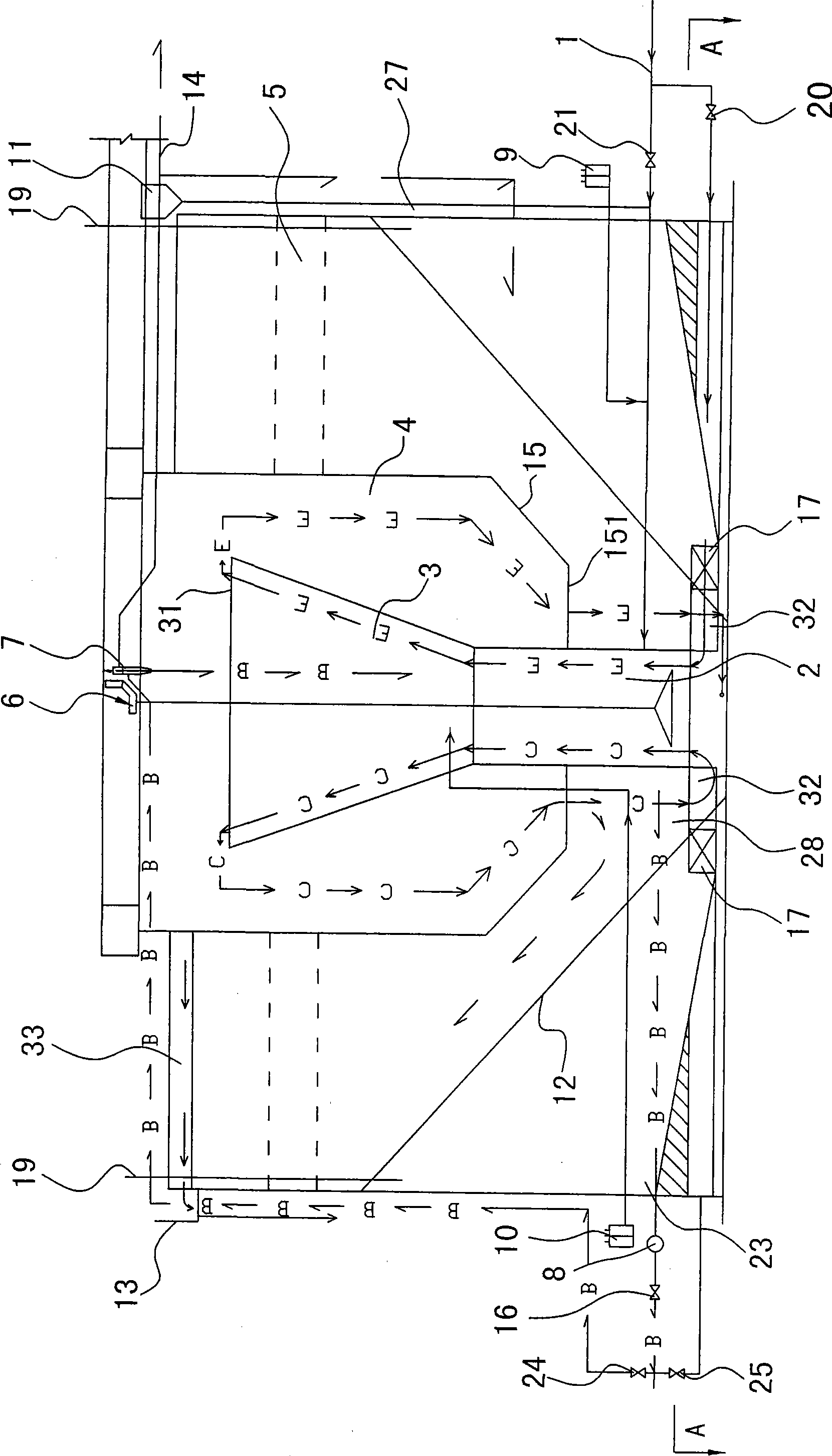

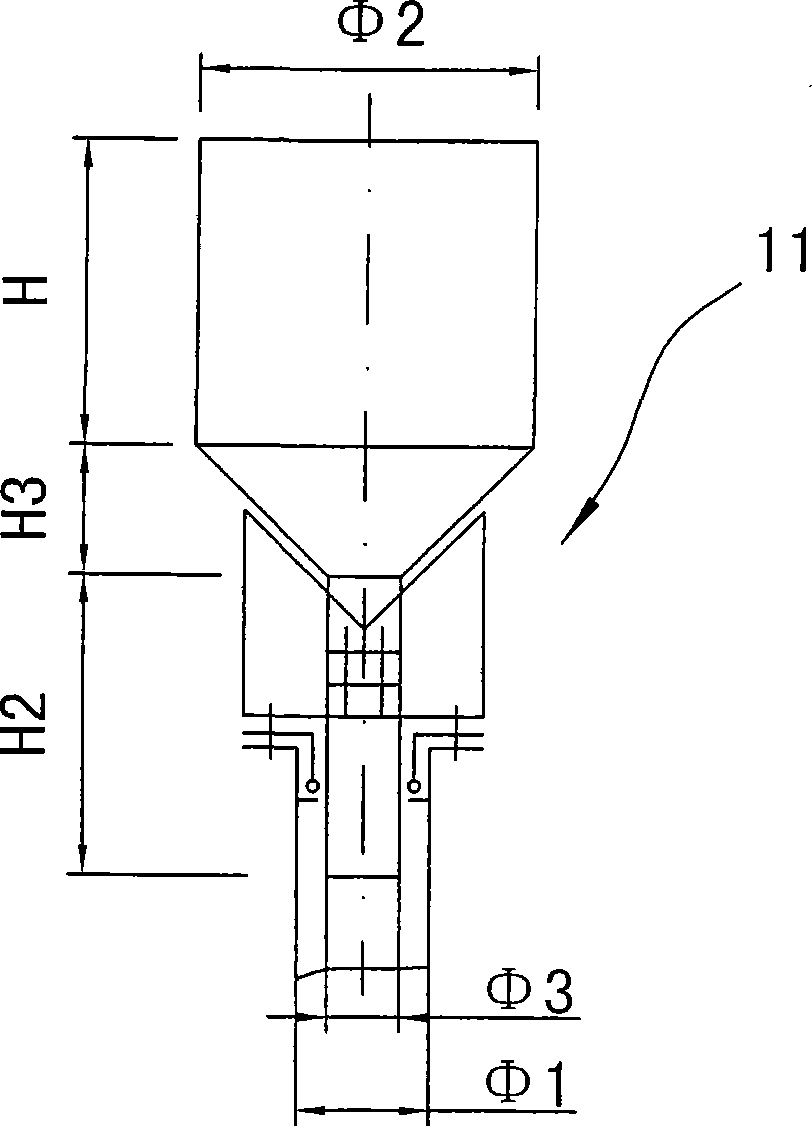

[0016] A nuclear double-circulation device with a nozzle at the front end (for water supply purification to implement double circulation) water inlet pipe 1 and water inlet control valve 21 are connected with a mixing water head control device 11 outside the water treatment structure (such as image 3 As shown), under the premise of satisfying the mixing water head, the excess energy will be released to avoid excessive turbulence in the flocculation chamber and affect the flocculation effect. The water body is sprayed into the mixing chamber 2 from the tangential direction at a flow rate of ~3 m / s, and the coagulant added by the coagulant preparation system 9 upstream of the water inlet pipe 1 is about 20-30 mg / L and is fed from the lower end of the mixing chamber The inhaled return sludge is quickly mixed, and the coagulant is quickly diffused into the water body under the double action of the speed-adjusting stirring device 6 and the vortex. The mixing time is 15 to 20 second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com