Method for controlling solution crystal growth rate

A solution crystal growth, crystal growth technology, applied in the field of material science, can solve the problems of crystal growth rate control, solution leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

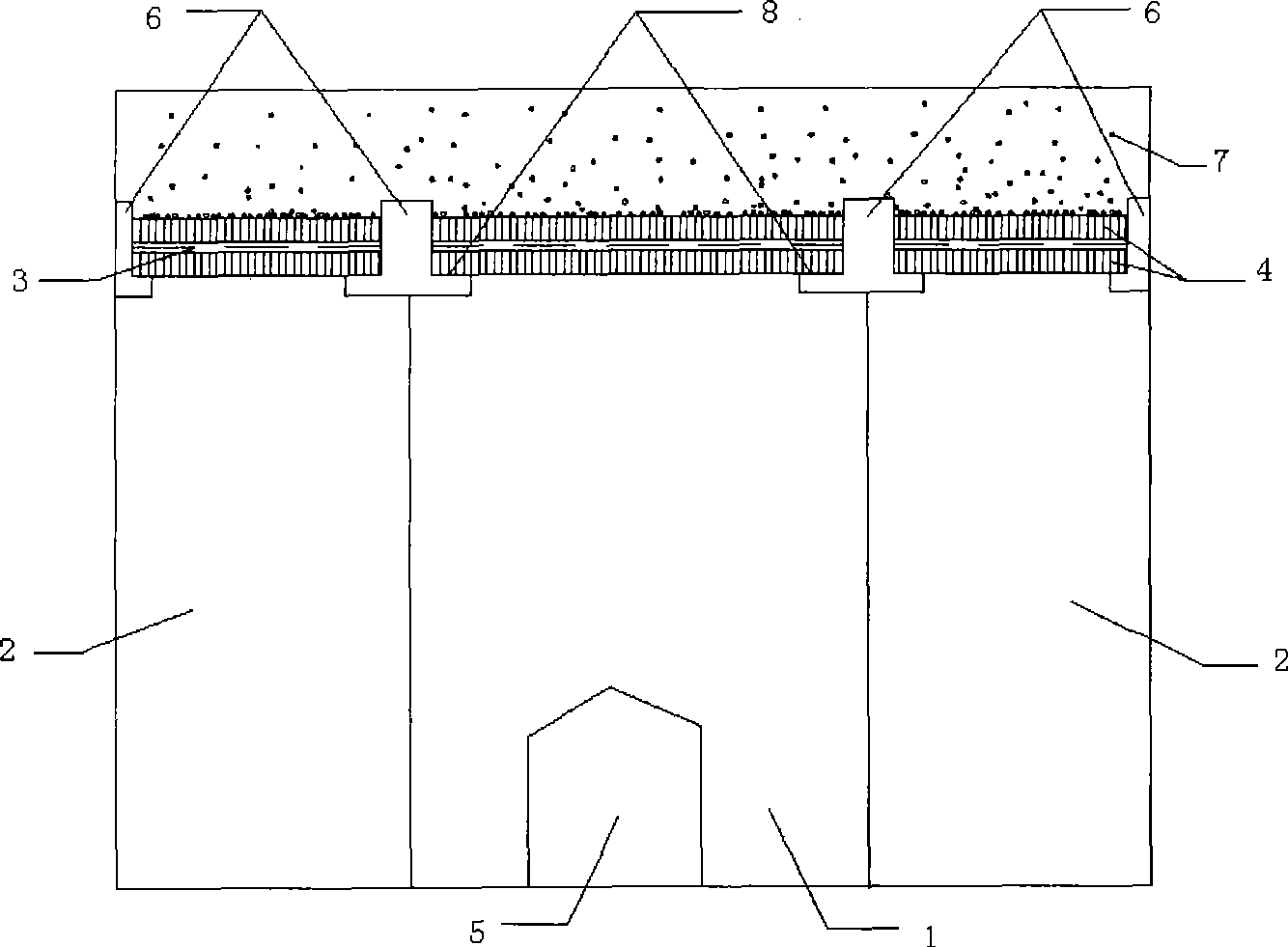

Embodiment 1

[0030] Take the growth of lithium iodate crystals as an example: prepare a saturated solution of lithium iodate near room temperature with a density of 1.5-1.55, take 680 ml of this lithium iodate solution and place it in a crystallizer (fix the lithium iodate seed crystal at the bottom of the crystallizer in advance ), using Huitian 906 silica gel to bond the stainless steel mesh-hydrophobic polytetrafluoroethylene microporous membrane-the edge of the stainless steel mesh to form a three-layer structure, and stick this three-layer structure to the ring on the top cover of the crystallizer On the step (the top cover of the crystallizer is processed into a 5 mm annular step in advance). The pore diameter of the polytetrafluoroethylene microporous membrane is 0.45 microns, and the evaporation area is 9 cubic centimeters. Use this three-layer structure to seal the crystallizer, and raise the temperature to 70°C. As time goes on, the solvent gradually evaporates to the outside of ...

Embodiment 2

[0032] Take the growth lithium iodate crystal as an example: Take the growth lithium iodate crystal as an example: prepare a saturated solution of lithium iodate near room temperature with a density of 1.5-1.55, and get 680 milliliters of this lithium iodate solution and place it in a crystallizer (previously placed in a crystallizer) Lithium iodate seed crystals are fixed at the bottom of the container), using Huitian 906 silica gel to bond a three-layer structure composed of stainless steel mesh-hydrophobic polytetrafluoroethylene microporous membrane-stainless steel mesh edges, and this three-layer structure Stick on the annular step on the top cover of the crystallizer (the top cover of the crystallizer is processed into a 5 mm annular step in advance). The PTFE microporous membrane has a pore size of 1 micron and an evaporation area of 9 cubic centimeters. Use this three-layer structure to seal the crystallizer, and raise the temperature to 70°C. As time goes on, the so...

Embodiment 3

[0034] Take the growth lithium iodate crystal as an example: Take the growth lithium iodate crystal as an example: prepare a saturated solution of lithium iodate near room temperature with a density of 1.5-1.55, and get 680 milliliters of this lithium iodate solution and place it in a crystallizer (previously placed in a crystallizer) Lithium iodate seed crystals are fixed at the bottom of the container), using Huitian 906 silica gel to bond a three-layer structure composed of stainless steel mesh-hydrophobic polytetrafluoroethylene microporous membrane-stainless steel mesh edges, and this three-layer structure Stick on the ring step on the top cover of the crystallizer (the top cover of the crystallizer is processed into a 5mm ring step in advance). The pore diameter of the polytetrafluoroethylene microporous membrane is 0.8 microns, and the evaporation area is 9 cubic centimeters. Use this three-layer structure to seal the crystallizer, and raise the temperature to 70°C. As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com