Grounding-electrode wind-cooling plate type ozone-producing unit

A technology for generating units and grounding electrodes, which is applied in the field of plasma physics and can solve the problems of low discharge electric field strength, easy breakage, and low ozone generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

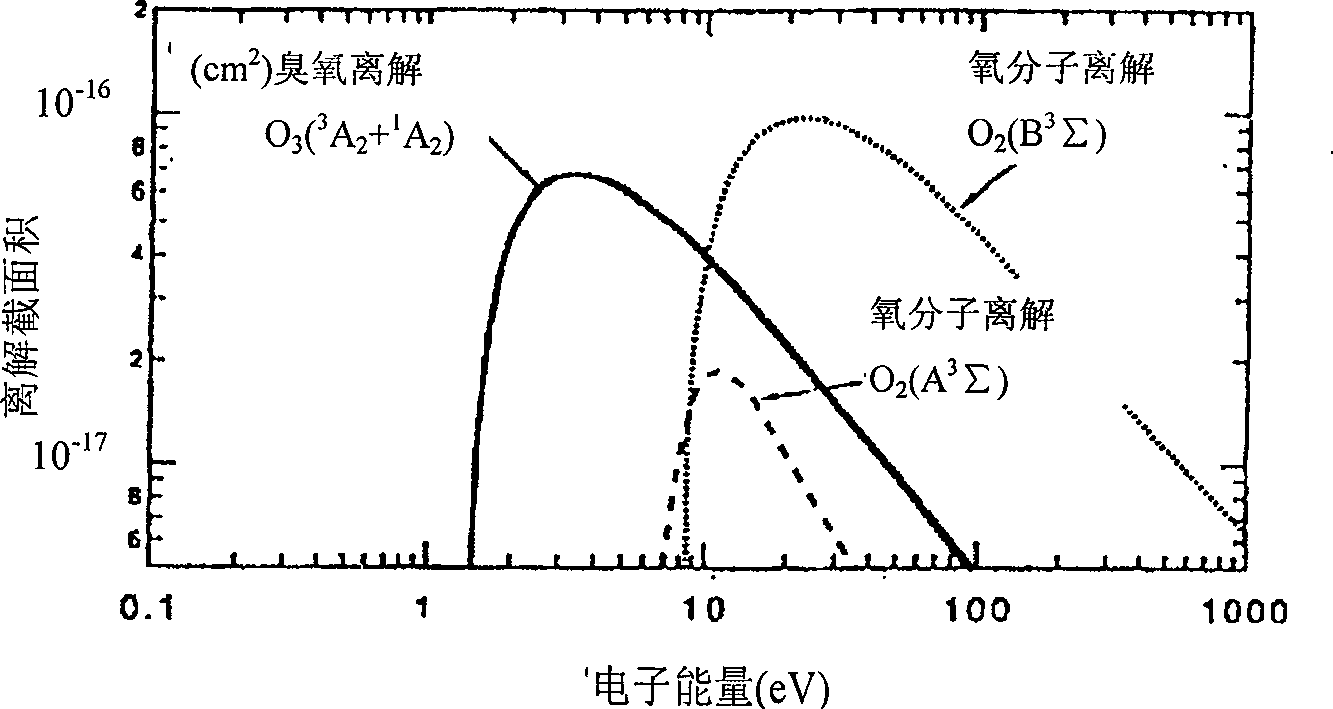

[0019] from figure 1 According to the relationship curve between the dissociation cross-sectional area of the ozone molecule and the oxygen molecule and the energy of the electron, it can be seen that the electrons accelerated by the electric field are vertically excited to dissociate the oxygen molecule, from O 2 (x 3 Σg - ) ground state excitation to O 2 (A 3 Δu + ) state, the required vertical excitation energy is 6.1eV, which is a forbidden transition; from O 2 (X 3 Σg - ) ground state excitation to O 2 (B 3 ∑ u - ) state, the vertical excitation energy of oxygen molecules is 8.4eV; however, the excitation energy of ozone dissociation is 2eV, and when the electrons in the discharge gap obtain energy ≥ 8.4eV from the discharge electric field, oxygen molecules can decompose and ionize into oxygen atoms, ions and free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com