Diamond opposite vertex anvil inflating method and device

A technology of diamond topping and inflating device, which is applied in the process of applying ultra-high pressure and other directions, can solve the problems of large consumption of inflatable body, complex pressure device and remote pressurizing equipment, etc., to improve the success rate of experiments, and the method is simple and easy. The effect of running, less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

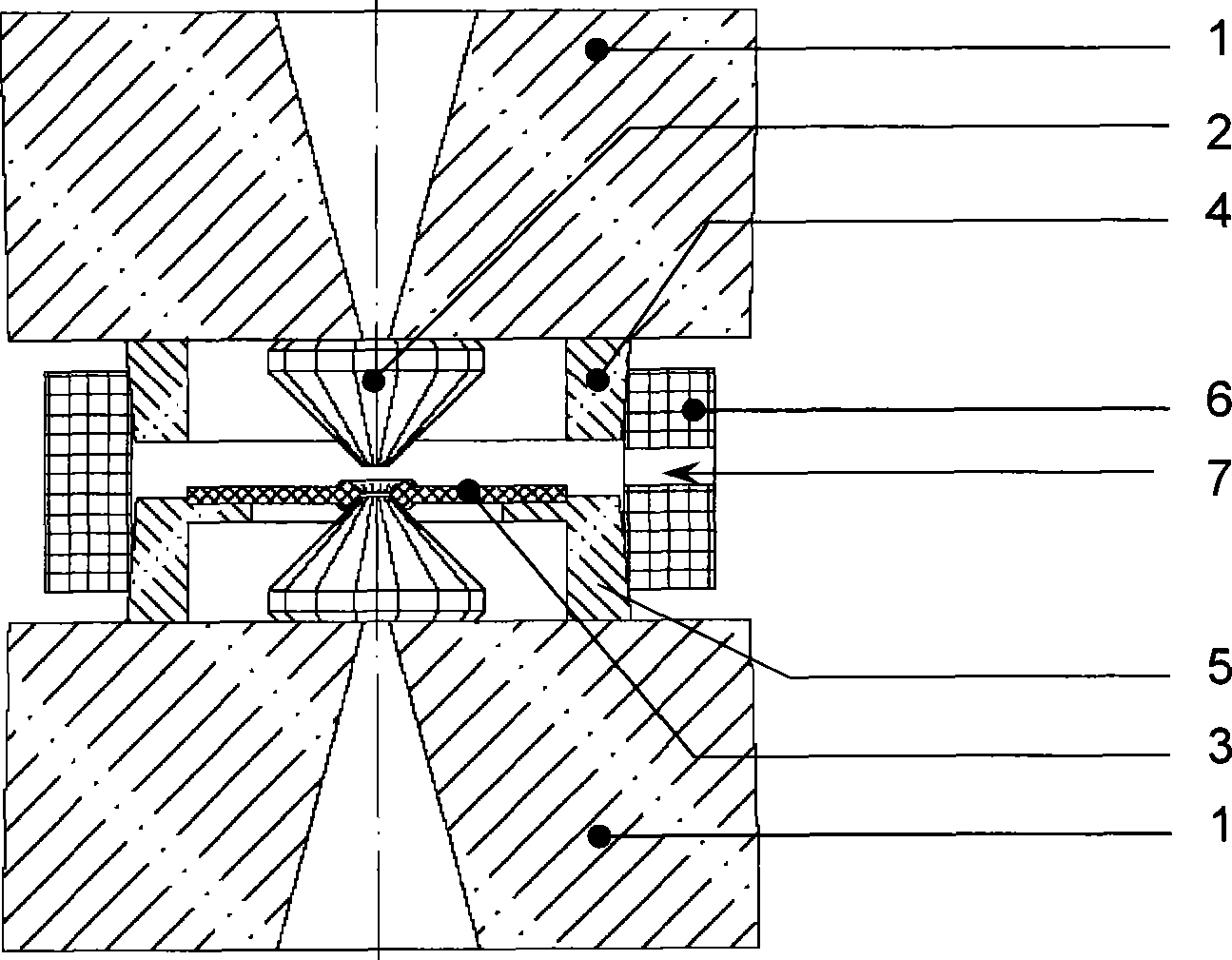

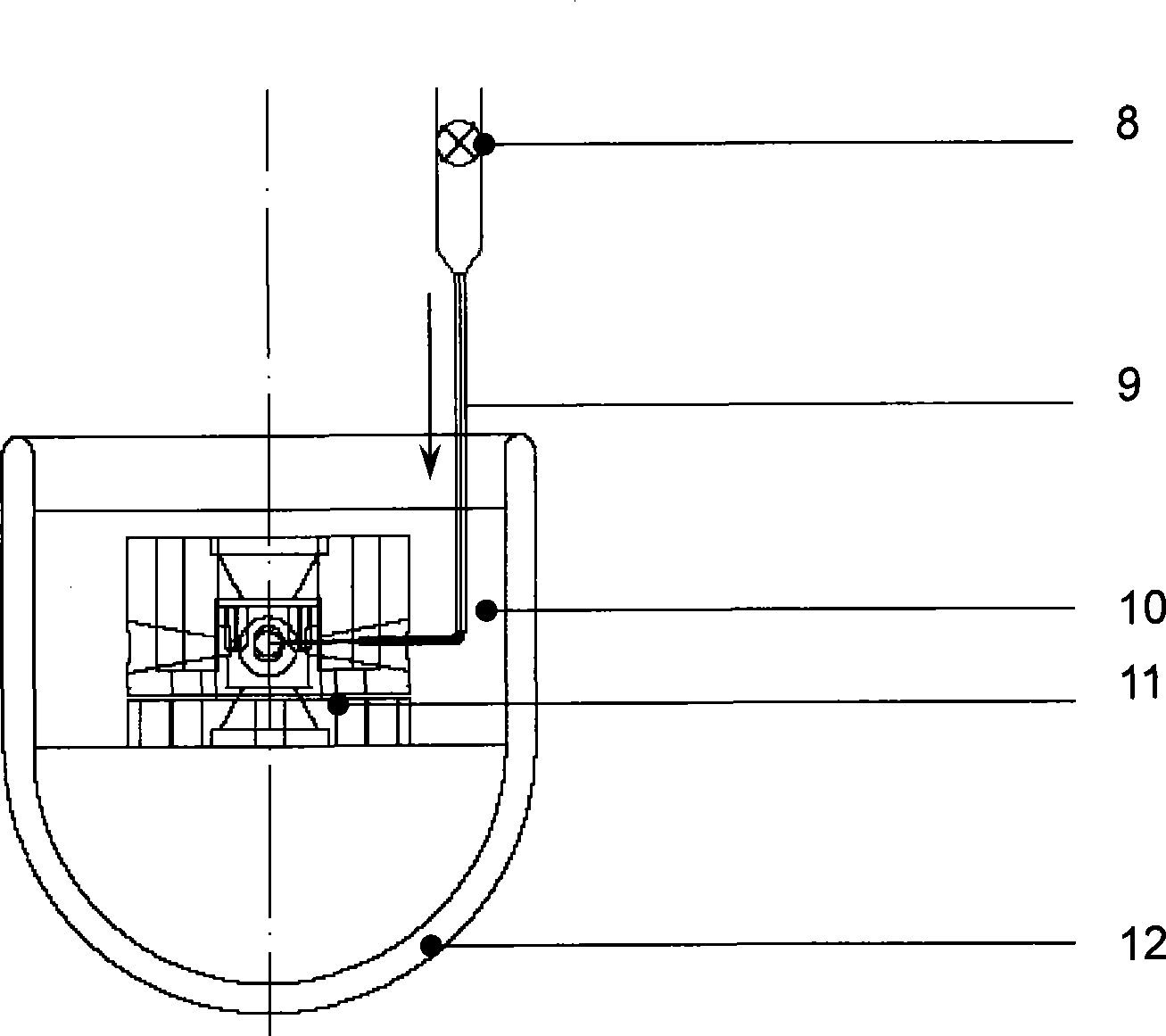

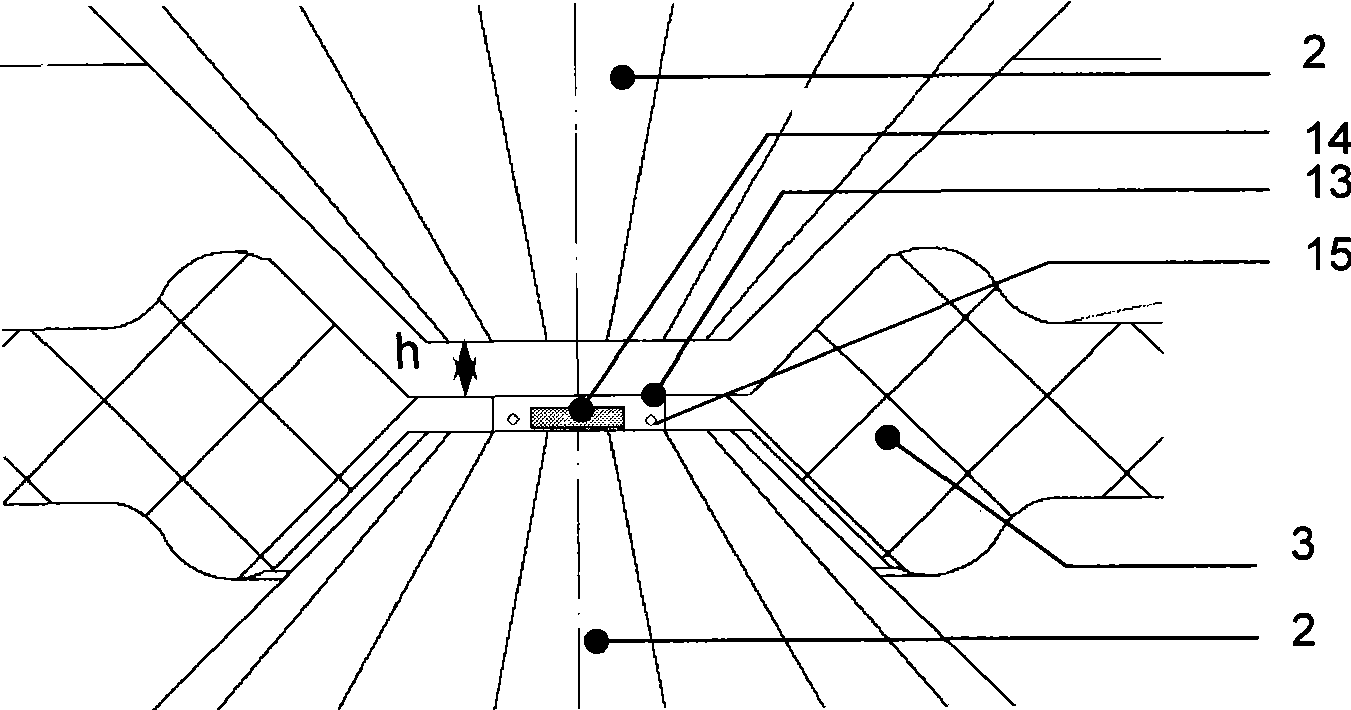

[0025] like Figure 1-3 As shown, the diamond anvil inflation device of the present invention includes a diamond anvil body, a gas introduction device, a sealing device and a cooling device, and the sealing device includes a gasket 3, a plastic connector 6 and an upper and a lower sealing frame 4, 5. The diamond anvil body includes a diamond anvil 2 and a spacer 1 . The diamond anvil 2 is fixed on the block 1, and the upper and lower sealing frames 4, 5 are arranged on the block 1, and the diamond anvil 2 is wrapped therein. The upper and lower sealing frames 4 and 5 are connected by a plastic connector 6, the plastic connector 6 is made of elastic and self-lubricating materials, through the upper and lower sealing frames 4, 5 and the plastic connector 6, the upper and lower A sealed cavity is formed between the pads 1 . A gasket 3 is arranged on the lower sealing frame 5 to divide the sealing chamber into upper and lower parts. The gasket 3 has been pre-pressed and a sample...

Embodiment 2

[0026] Embodiment 2: Inert gas Ar is filled in the DAC sample cavity by using a low-temperature cooling and gas charging device.

[0027] The preparation method of this embodiment comprises the following steps:

[0028] 1) Fix the gasket 3 pre-compressed to an appropriate thickness and drill holes between the opposing anvils of the DAC device and record the zero position of the compression screw. We use a T301 stainless steel sheet with an initial thickness of 250 μm as a gasket. When the diameter of the end face of the diamond anvil is 500 μm, the final thickness of the pre-pressed gasket 3 is not greater than 40 μm, and the diameter of the sample chamber 13 is about 1 / 1 of the diameter of the end face of the diamond anvil. 3. A sample sheet 14 of appropriate size and thickness and a pressure mark 15 are placed in the sample cavity 13 according to the needs of the experiment. Here we use ruby as the pressure mark.

[0029] 2) Since the gas to be inflated is high-purity Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com