Shock absorber inflation tooling and operation method

A shock absorber and tooling technology, used in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of inability to complete inflation at one time, many defective products, and poor safety, and achieve sealing performance. The effect of good, high safety and high success rate of inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

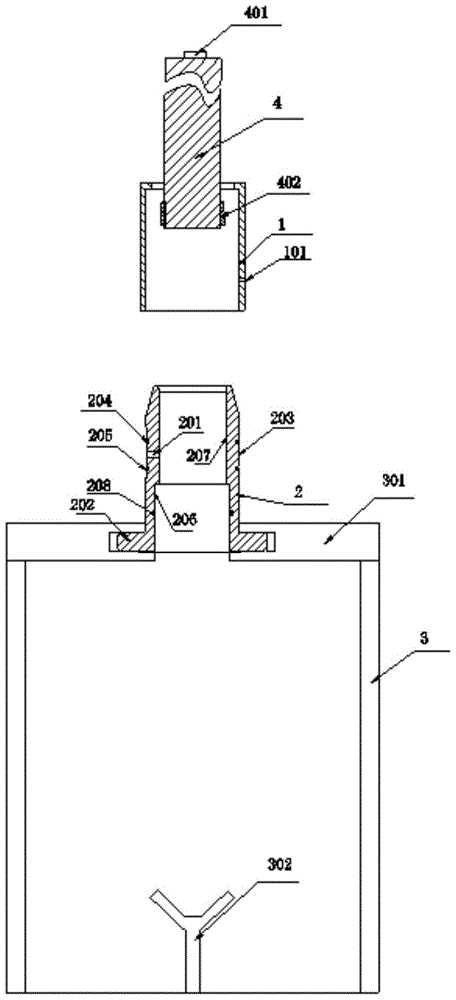

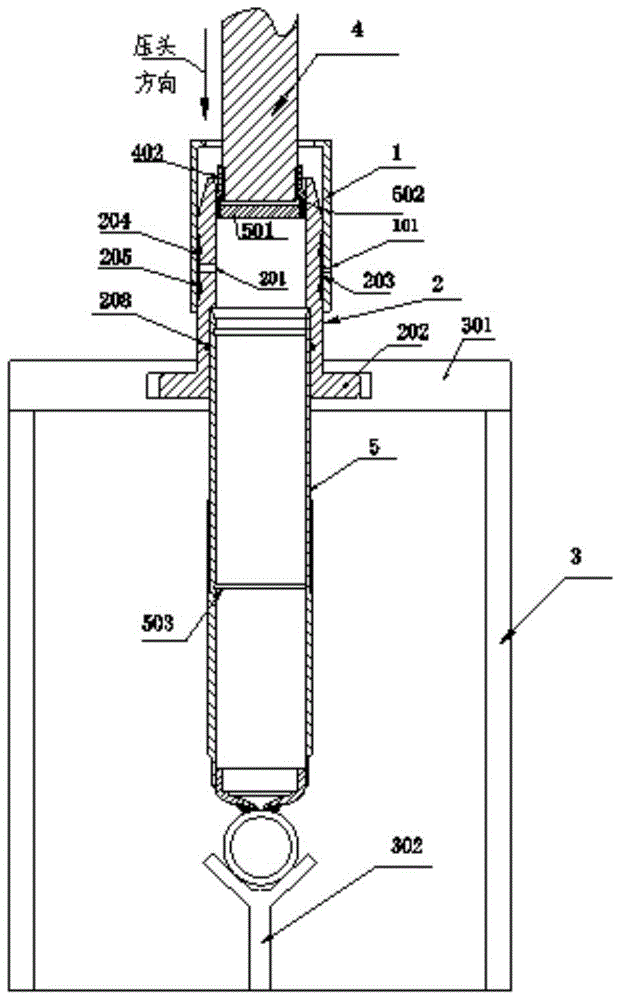

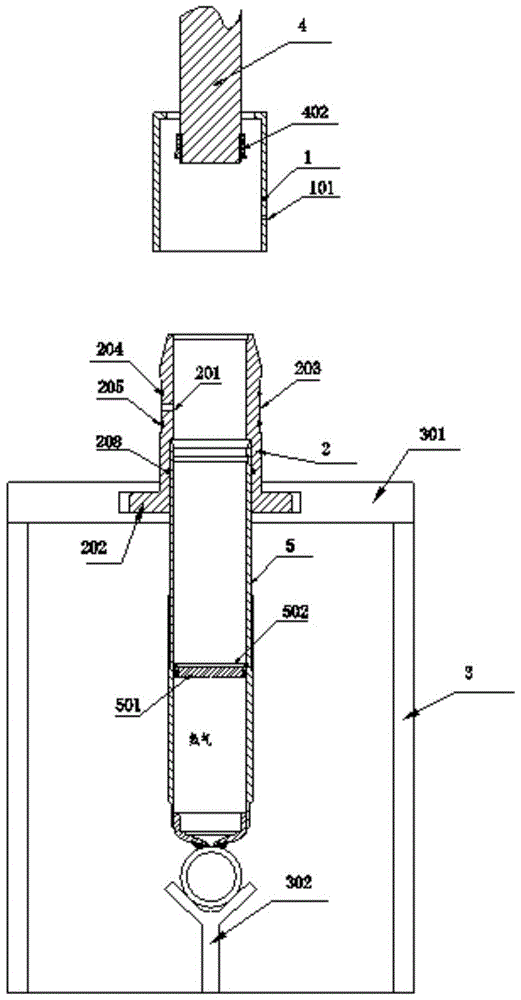

[0033] Such as figure 1 As shown, the present invention provides a shock absorber inflatable tool, including: an air seal 1, an inflatable sleeve 2 and a bracket 3; the air seal 1 is provided with a first inflation hole 101, and the air seal 1 can The sleeve is pressed on the inflatable sleeve 2 , the second inflation hole 201 is arranged on the inflatable sleeve 2 , and the inflatable sleeve 2 is erected on the bracket 3 .

[0034] Wherein, the gas sealing sleeve 1 is a cylinder with one end open, and the closed end is fixedly connected to the pressure head of the press-fitting equipment, and the pressure head 4 extends downward into the gas sealing sleeve 1 . A sensor 401 is installed on the upper end of the inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com