Air cooler for cooling DC converter valve and fabrication technology thereof

A technology of air coolers and DC converter valves, which is applied in the direction of electrical components, heat exchange equipment, and electric solid devices, and can solve the problem that the air cooler cannot be used in the cooling system of DC converter valves, so as to achieve reasonable process layout and reduce Effect of thermal resistance and surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

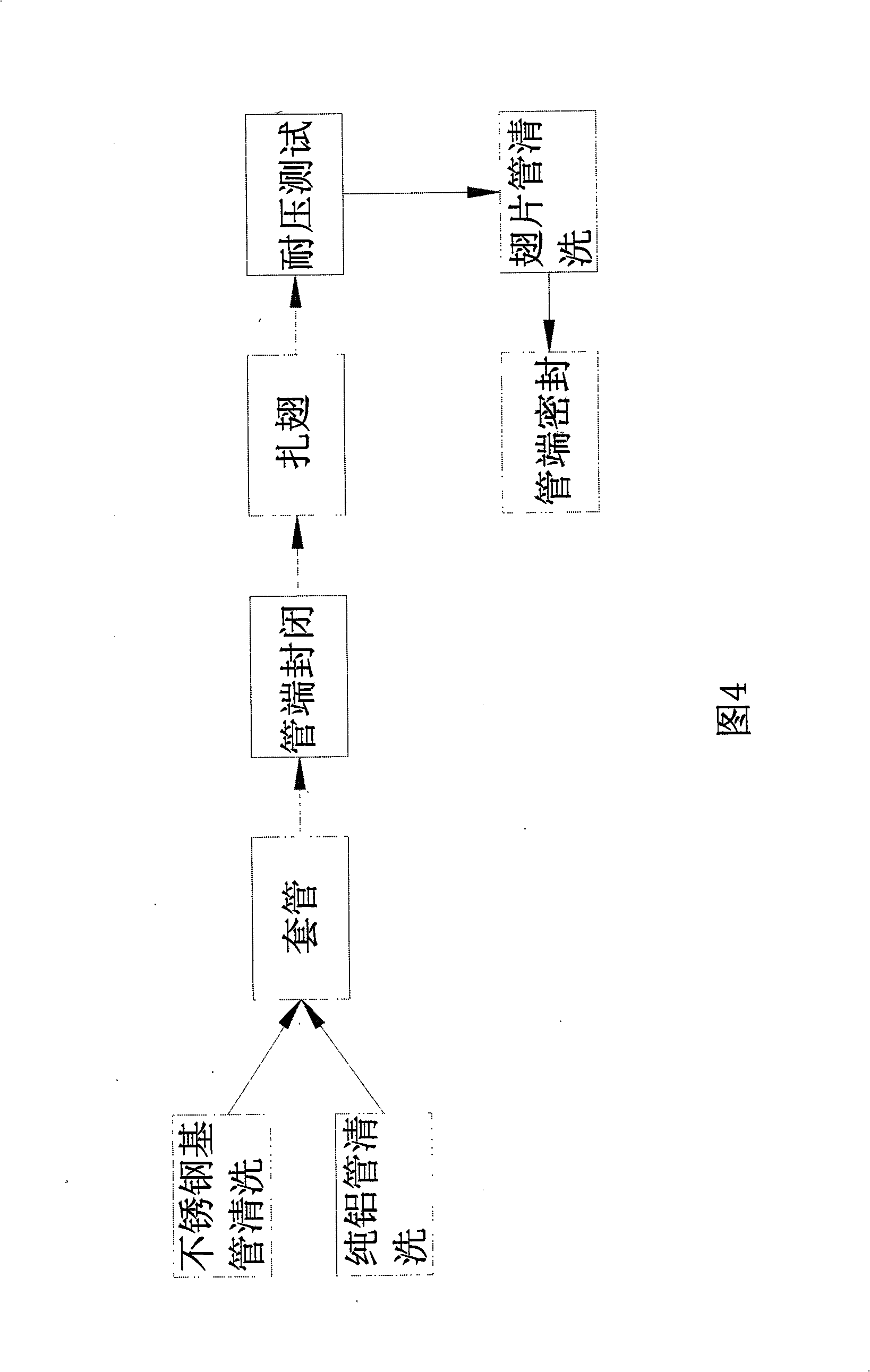

[0051] Referring to Fig. 1 and Fig. 2, an air cooler for cooling DC converter valves includes a pipe box 20 composed of a side plate 24, an upper sealing plate 25 and a lower sealing plate 26, and a partition 27 is arranged in the pipe box 20 to The inside of the pipe box 20 is divided into a plurality of relatively independent compartments, and a stainless steel tube bundle composed of several stainless steel finned tubes 21 is installed in the compartments. The base tube is made of 06Cr18Ni9 or 06Cr17Ni12Mo2 stainless steel, and the heat sink is formed by rolling an aluminum tube set on the base tube 21.

[0052] The manufacturing process of the air cooler for cooling the DC converter valve of the tube box of the present invention includes the manufacturing process of the stainless steel finned tube and the tube box.

[0053] With reference to Fig. 4, the manufacturing technological process of stainless steel finned tube of the present invention is as follows:

[0054] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com