Broadband-spectrum optical glass and method of producing the same

An optical glass and wide-spectrum technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of lack of short-wave information, full-band high-transmittance that cannot be seen in the visible band, and the impact of imaging quality, etc., to achieve low cost, Easy dispersion and chromatic aberration, effects of eliminating dispersion and chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

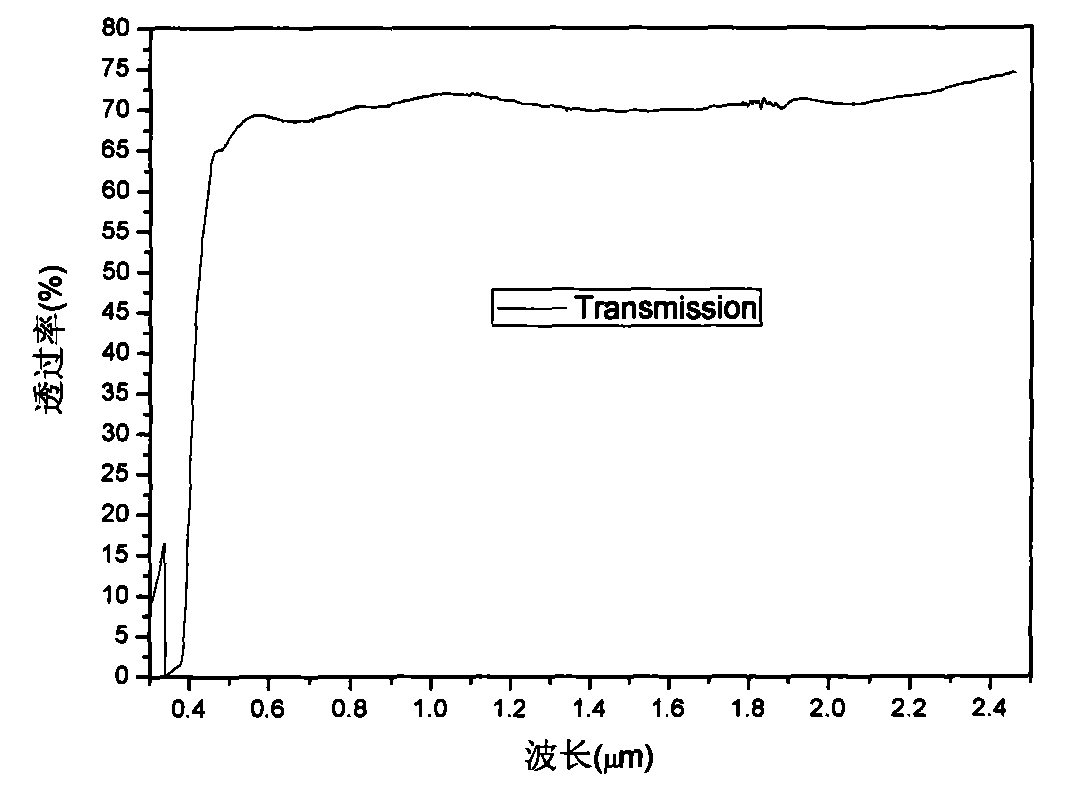

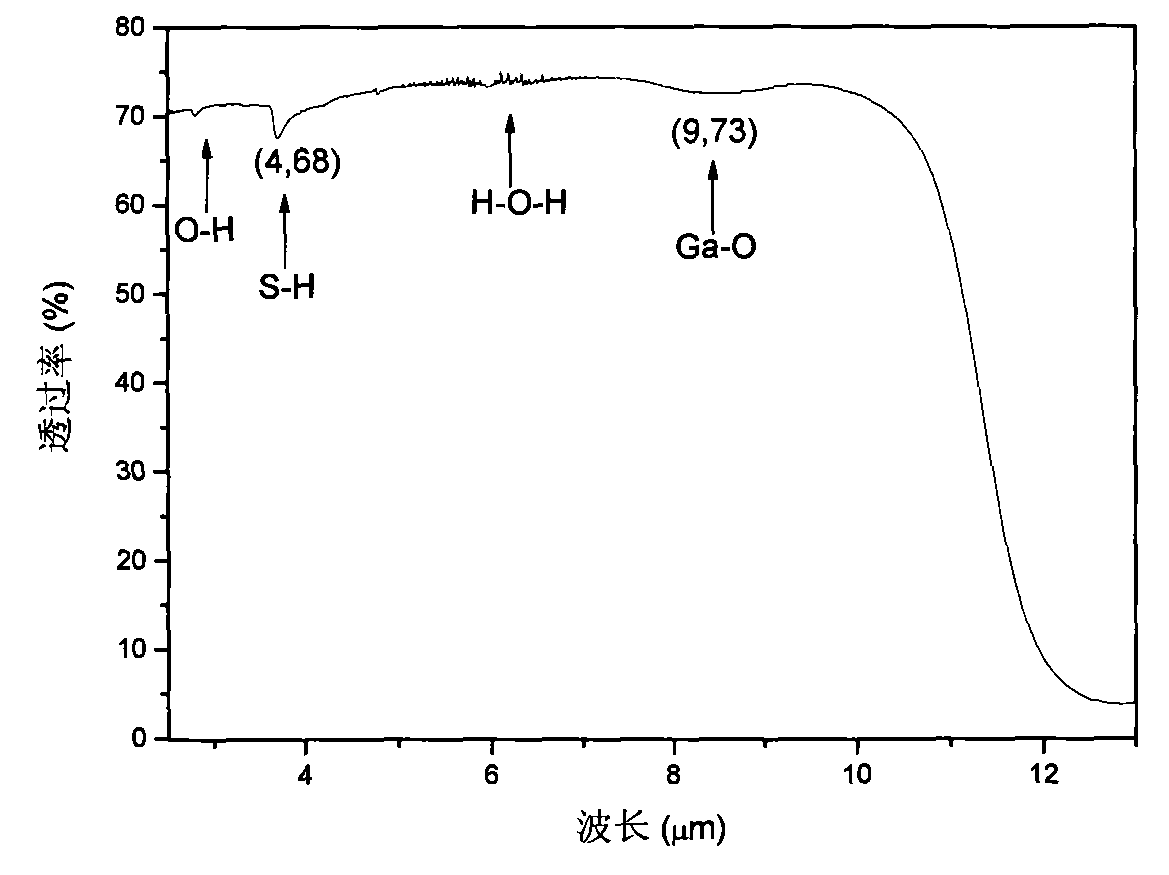

[0024] The glass composition is glass and the composition is 30Ga 2 S 3 -10GeS 2 -58CsCl-2ZrS 2

[0025] With ≥99.99% high-purity elemental Ga, Ge, S and compounds CsCl, ZrS 2 (≥99.9%) is that the raw materials are mixed according to the above-mentioned molar percentages to prepare 20 grams of mixture; Preheating, when the vacuum is 6×10 -4 When Pa is sealed with an oxyhydrogen flame; put the sealed H-shaped double-tube quartz ampoule with the glass mixture into a double-tube distillation furnace for distillation and purification (cold end 100°C, hot end 300°C) and Reduction of some oxides. The purity of the purified Ge, Ga and S can reach ≥99.999%. The double tube was then sealed with an oxyhydrogen flame, and the individual ampoules containing the intact glass frit were removed. Put the purified independent quartz ampoule into a swing furnace, slowly raise the temperature to 950°C, shake and melt for 5 hours, then cool down to 600°C, take it out, put it in cold water...

Embodiment 2

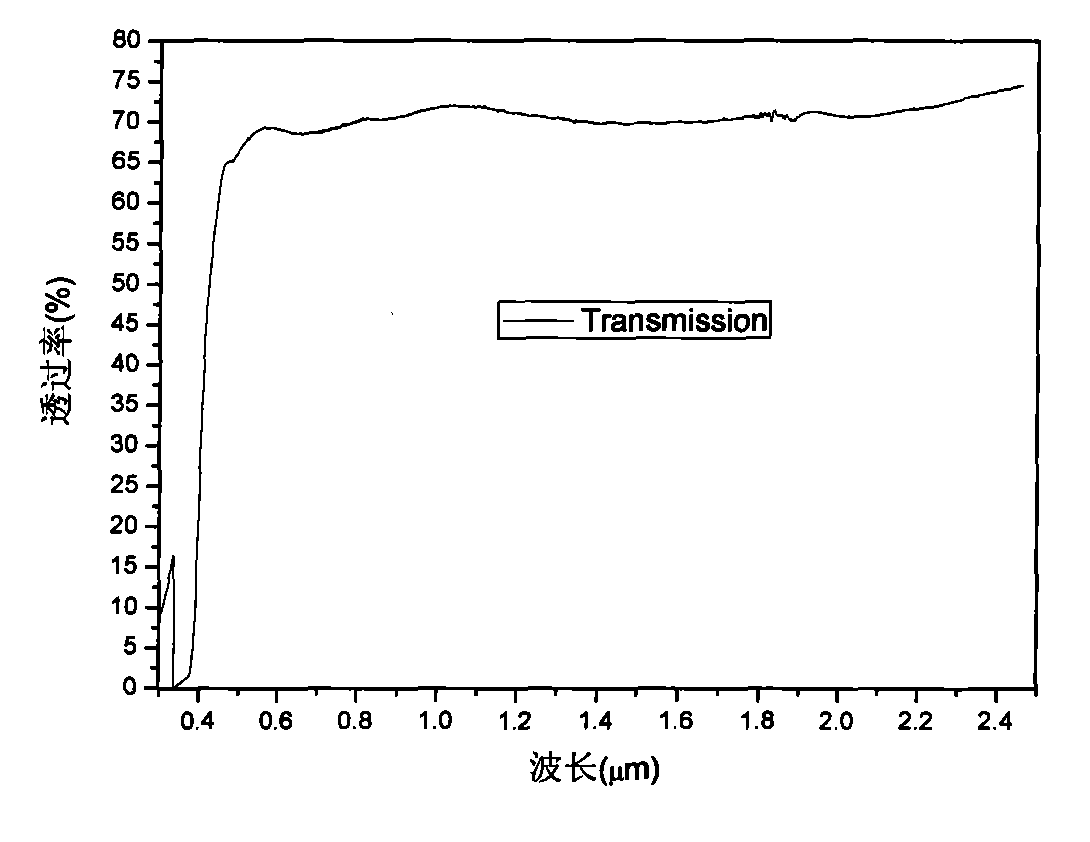

[0027] The glass composition is glass and the composition is 26Ga 2 S 3 -20 GeS 2 -52CsCl-2ZrS 2

[0028] The preparation method of glass is the same as that of Example 1, with ≥99.99% high-purity simple Ga, Ge, S and compounds CsCl, ZrS 2 (≥99.9%) is the raw material mixed according to the above mole percentage to prepare 20 grams of glass mixture, and the batch is put into a dehydroxylated quartz ampoule to vacuumize (0.002 grams of magnesium strips are placed in advance), and at the same time, the Preheating, when the vacuum is 7×10 -4 When Pa is sealed with an oxyhydrogen flame, put the H-shaped double-tube quartz ampoule filled with glass mixture into a double-tube distillation furnace for distillation and purification (cold end 100°C, hot end 300°C) and reduce some oxides. The purity of the purified Ge, Ga and S can reach ≥99.999%. The double tube was then sealed with an oxyhydrogen flame, and the individual ampoules containing the intact glass frit were removed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com