Production of novel carbon silica aerogel electrode and uses thereof

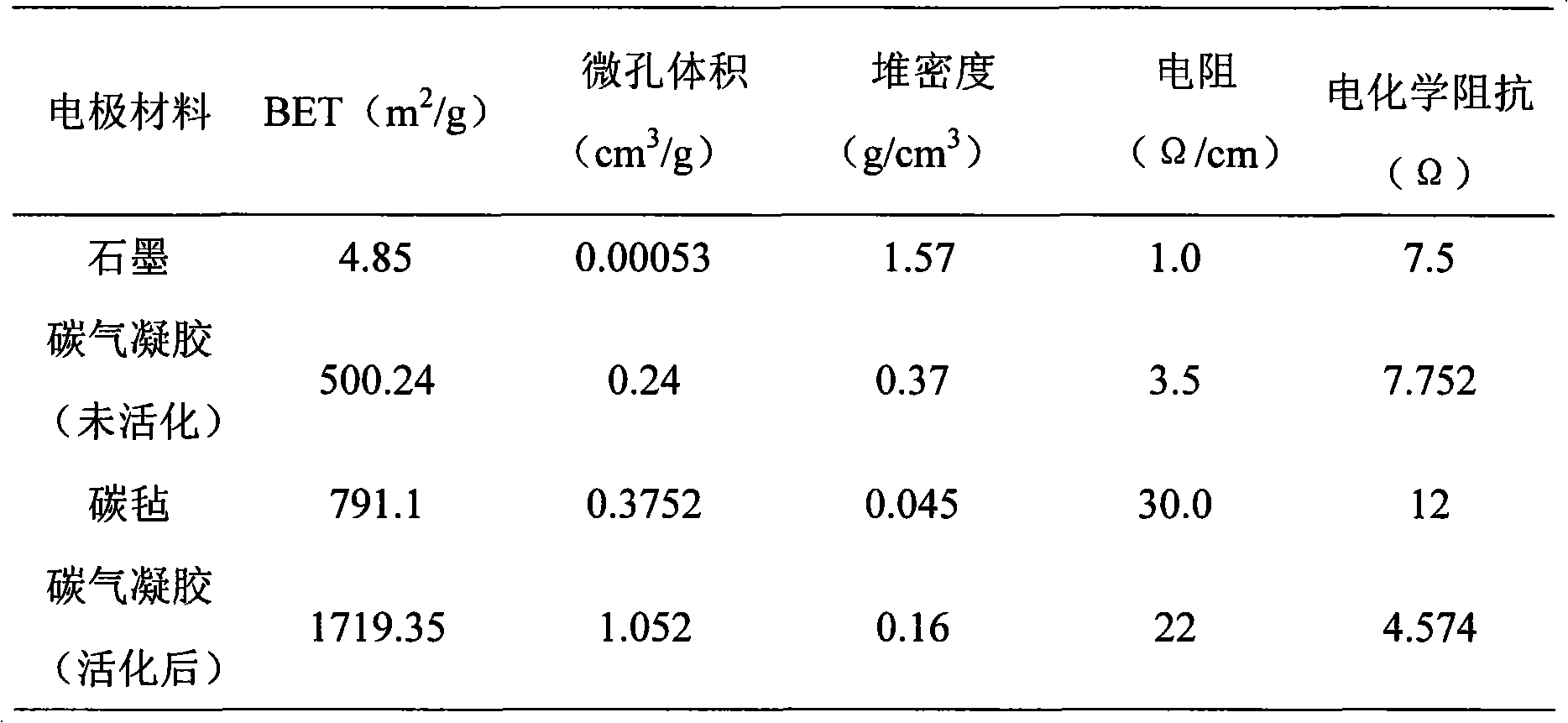

A carbon aerogel and aerogel technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of no fixed continuous structure, no electric adsorption electrodes, low specific surface area, etc., and achieve controllable appearance shape, high The effect of high conductivity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A kind of preparation method of carbon airgel electrode, comprising: (1) sol-gel phenolic polymerization method, take resorcinol, formaldehyde as raw material, sodium carbonate (or sodium hydroxide) is catalyst, under certain molar ratio Stand to obtain the phenolic resin with network structure;

[0027] (2) Prepare the mold according to the appearance size of the electrode material required by the experiment. The mold is generally made of glass. According to the thickness of the required electrode, adjust the spacing distance to obtain a phenolic resin sheet that meets the requirements. The general thickness is controlled between 5 and 10mm. .

[0028] The bulk phenolic resin obtained after standing still is replaced by solvent in acetone with low surface tension. After 5-7 days, the water molecules in the network structure are replaced by acetone, and then dried at room temperature. It takes about 5 days. ~7 days.

[0029] The dried airgel is heated to 600-1200° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com