Low-energy consumption nitrogen production method and apparatus

A low energy consumption, nitrogen technology, applied in refrigeration and liquefaction, nitrogen purification/separation, lighting and heating equipment, etc., can solve the problem of unsatisfactory energy consumption of air separation equipment, so as to avoid the increase of air humidity and reduce the humidity The effect of increasing the amount and improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

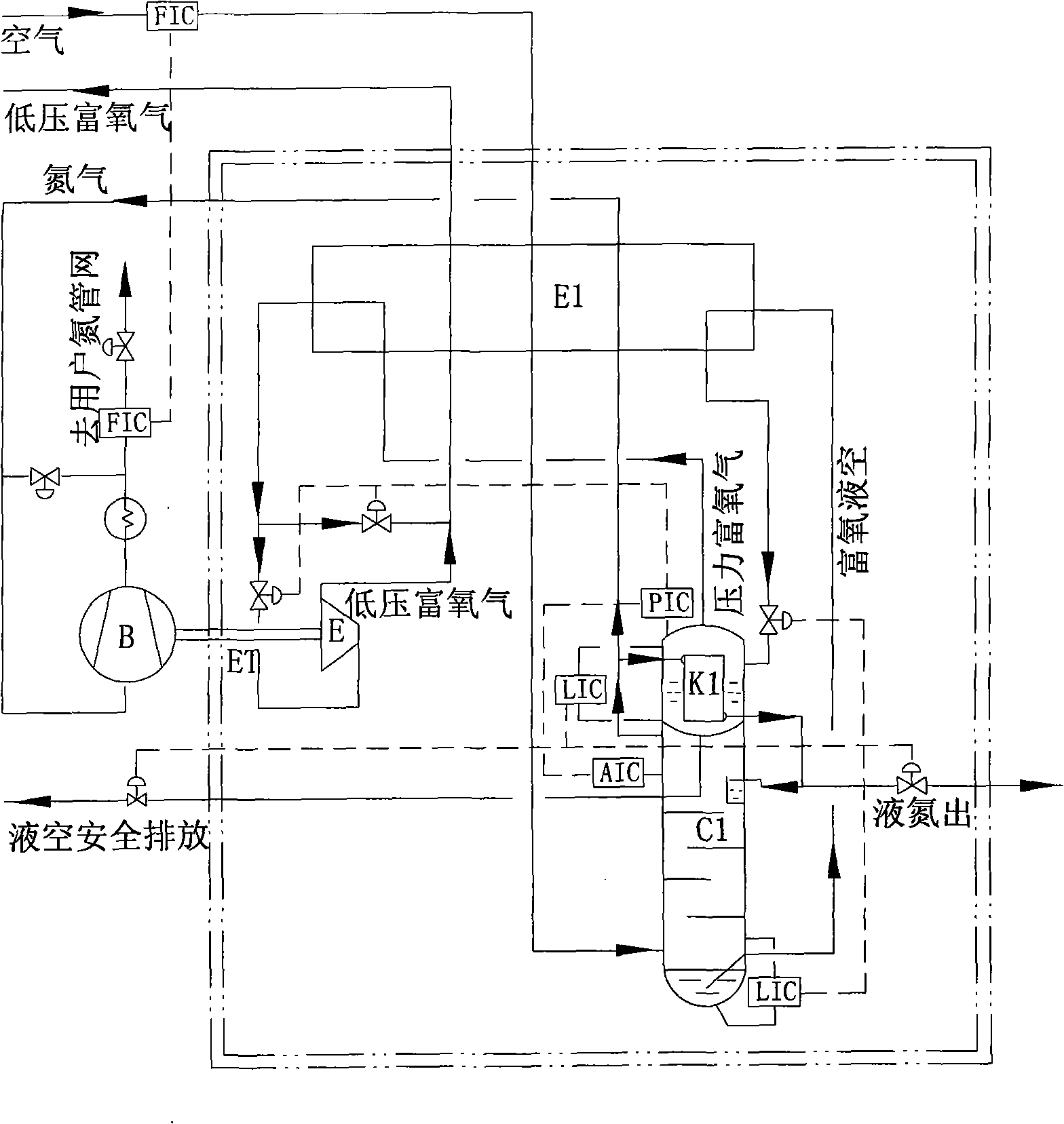

[0024] As shown in the figure, the nitrogen production process of the present invention is as follows:

[0025] a) The compressed and purified air is introduced into the heat exchanger E1, and is cooled to close to the liquefaction temperature by the return gas such as low-pressure oxygen-enriched, nitrogen and pressure-enriched oxygen in the heat exchanger through the pipeline;

[0026] b) The cooled air is sent to the rectification tower C1, where heat and mass transfer is carried out on the tray or packing from bottom to top in the rectification tower and the liquid from top to bottom. Different forms of rectification. Nitrogen is obtained at the top of the tower; oxygen-enriched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com