Carbon nanowall with controlled structure and method for controlling carbon nanowall structure

A carbon nanowall and structure control technology, applied in the field of carbon nanowall, can solve the problems of non-interconnection and inferior substrate orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] use figure 2 The plasma CVD apparatus shown, and the substrate 2 that is formed by silicon (Si) is arranged on the heater 3 in the chamber, introduces carbon source gas (C 2 f 6 ), while introducing hydrogen (H 2 ). At this time, the temperature of the heater 3 was set at 970°C.

[0033] The distance between the plate electrode 4 and the substrate 2 is set to 5 cm, and the electric output of the plasma generator 7 is 13.56 MHz and 100 W, so that capacitively coupled plasma is generated between the plate electrode 4 and the substrate 2 . In addition, inductively coupled plasma is generated in the introduction tube 6 by the inductive plasma generating source 8 . At this time, the output of the high-frequency output device 9 is 13.56 Hz and 400 W. The area of the parallel plate electrodes is 19.625cm 2 (Φ50mm).

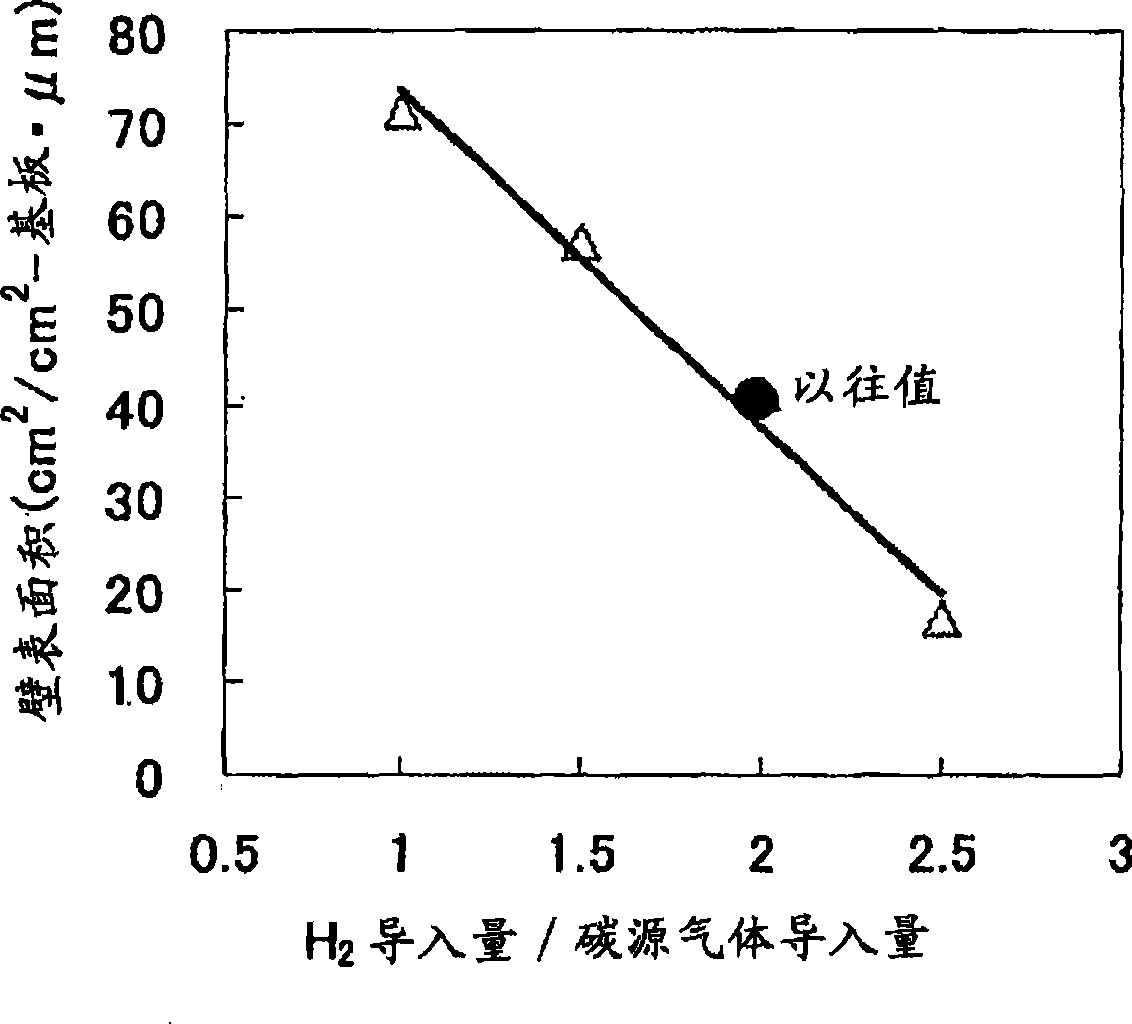

[0034] Carbon nanowalls (CNW) were grown on the substrate 2 by the plasma CVD method under the aforementioned conditions. The flow of carbon source gas...

Embodiment 2

[0039] It has been proved that in the same CVD process as in Example 1, by making H 2 It is also possible to independently control the crystallinity by varying the amount of gas introduced.

[0040] Figure 6 means H 2 The relationship between the amount of introduction and the crystallinity of the carbon nanowall determined by Raman spectroscopic analysis. The level of crystallinity was estimated using the half-value width of the D band of the Raman spectrum measured at an irradiation laser wavelength of 514.5 nm as an index. The smaller the half-value width of the D band, the higher the crystallinity. That is, by reducing H 2 The introduction amount can improve the crystallinity of the carbon nanowall. exist Figure 6 In , for reference, the D-band half-value width of Ketjen black (Ketjenblack) and the D-band half-value width of graphite, which are conventional carriers, are added. It can be seen that even carbon nanowalls can obtain high crystallinity higher than Ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com