Expansion controllable ultra high-early strength support saddle mortar material

A technology of support mortar and expansion agent, which is applied in the field of expansion-controllable super-early-strength support mortar material and its preparation, can solve the problems of no patent documents, etc., achieve excellent filling performance, improve crack resistance and impermeability Sexuality, the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

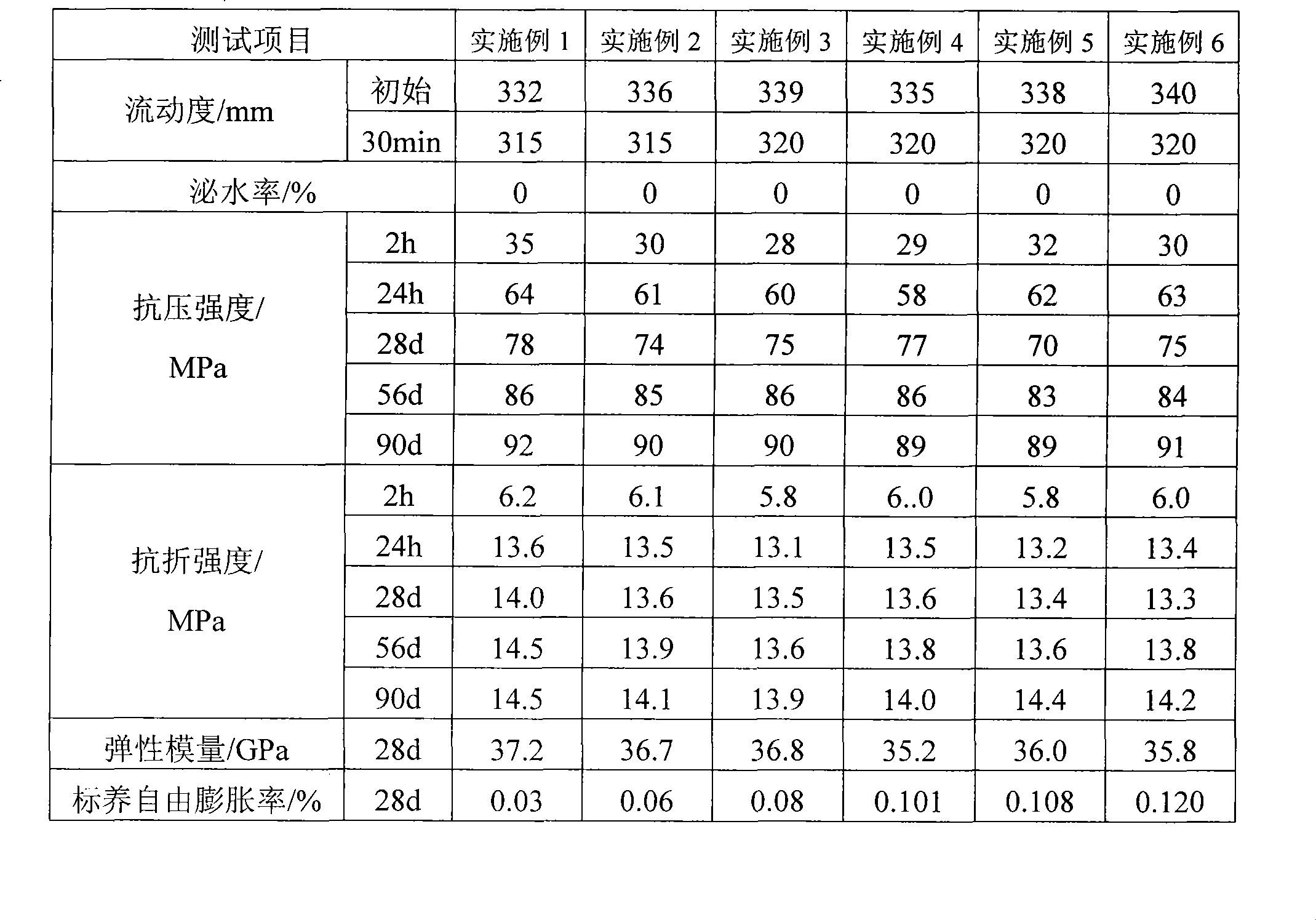

Examples

Embodiment 1

[0041] Rapid hardening sulfoaluminate cement 50%

[0042] Bulking agent 0%

[0043] 20 mesh ~ 40 mesh quartz sand 11%

[0044] 40 mesh ~ 60 mesh quartz sand 15%

[0045] 60 mesh ~ 70 mesh quartz sand 14%

[0046] 70 mesh ~ 100 mesh quartz sand 9%

[0047] Boric acid 0.4%

[0048] Aluminum sulfate: calcium fluoride = 1:1 0.2%

[0049] Naphthalenesulfonate superplasticizer (powder) 0.35%

[0050] Silicone defoamer 0.04%

[0051] 6mm polypropylene fiber 0.01%

[0052] The dry powder mortar automatic production equipment is adopted to automatically measure the above-mentioned components in proportion, automatically feed materials, automatically stir evenly, and automatically pack to form finished products.

Embodiment 2

[0054] Low Alkali Sulphoaluminate Cement 49%

[0055] Alum stone expander 2%

[0056] 20 mesh ~ 40 mesh quartz sand 10%

[0057] 40 mesh ~ 60 mesh quartz sand 16%

[0058] 60 mesh ~ 70 mesh quartz sand 14%

[0059] 70 mesh ~ 100 mesh quartz sand 8%

[0060] Citric acid 0.4%

[0062] Polycarboxylate superplasticizer (powder) 0.2%

[0063] Silicone defoamer 0.03%

[0064] 3mm polypropylene fiber 0.02%

[0065] The dry powder mortar automatic production equipment is adopted to automatically measure the above-mentioned components in proportion, automatically feed materials, automatically stir evenly, and automatically pack to form finished products.

Embodiment 3

[0067] Rapid hardening sulfoaluminate cement 46%

[0068] UEA expander 4%

[0069] 20 mesh ~ 40 mesh quartz sand 10%

[0070] 40 mesh ~ 60 mesh quartz sand 15%

[0071] 60 mesh ~ 70 mesh quartz sand 14%

[0072] 70 mesh ~ 100 mesh quartz sand 9%

[0073] Borax 0.3%

[0075] Naphthalenesulfonate superplasticizer (powder) 0.4%

[0076] Silicone defoamer 0.04%

[0077] 9mm polypropylene fiber 0.01%

[0078] The dry powder mortar automatic production equipment is adopted to automatically measure the above-mentioned components in proportion, automatically feed materials, automatically stir evenly, and automatically pack to form finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com