Double computer hot standby automatic passing neutral section device

An automatic over-phase, dual-machine hot-standby technology, applied in transportation and packaging, vehicle route interaction equipment, railway car body parts, etc., can solve the problems that are prone to traffic accidents, flight attendant traffic accidents, and high output contact failure rates. Achieve the effect of improving work performance and safety factor, ensuring operational safety, and realizing fully automated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with drawings and embodiments.

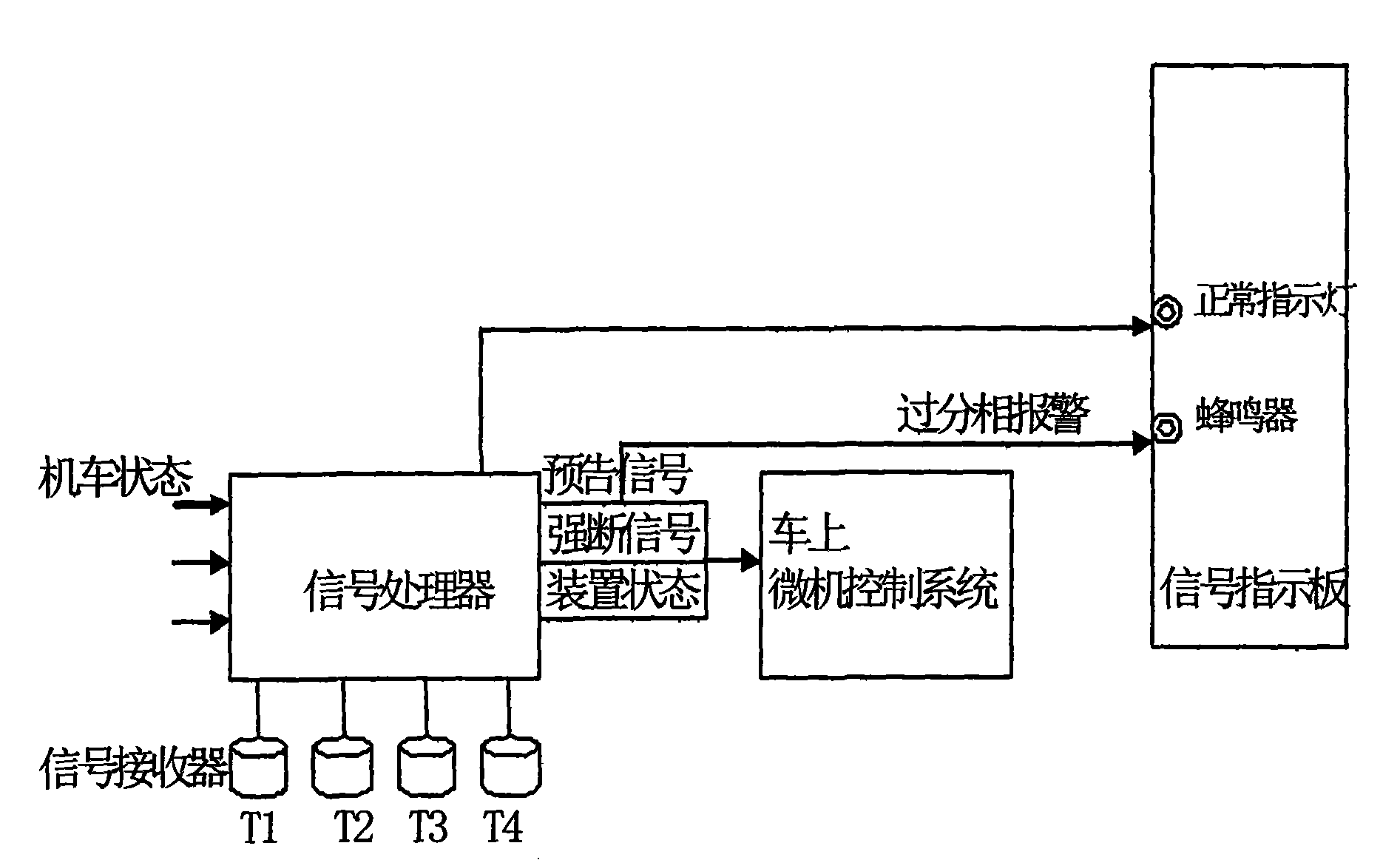

[0062] Such as figure 1 A dual-machine hot-standby automatic phase separation device shown includes a signal processor, a signal receiver and a signal indicator board.

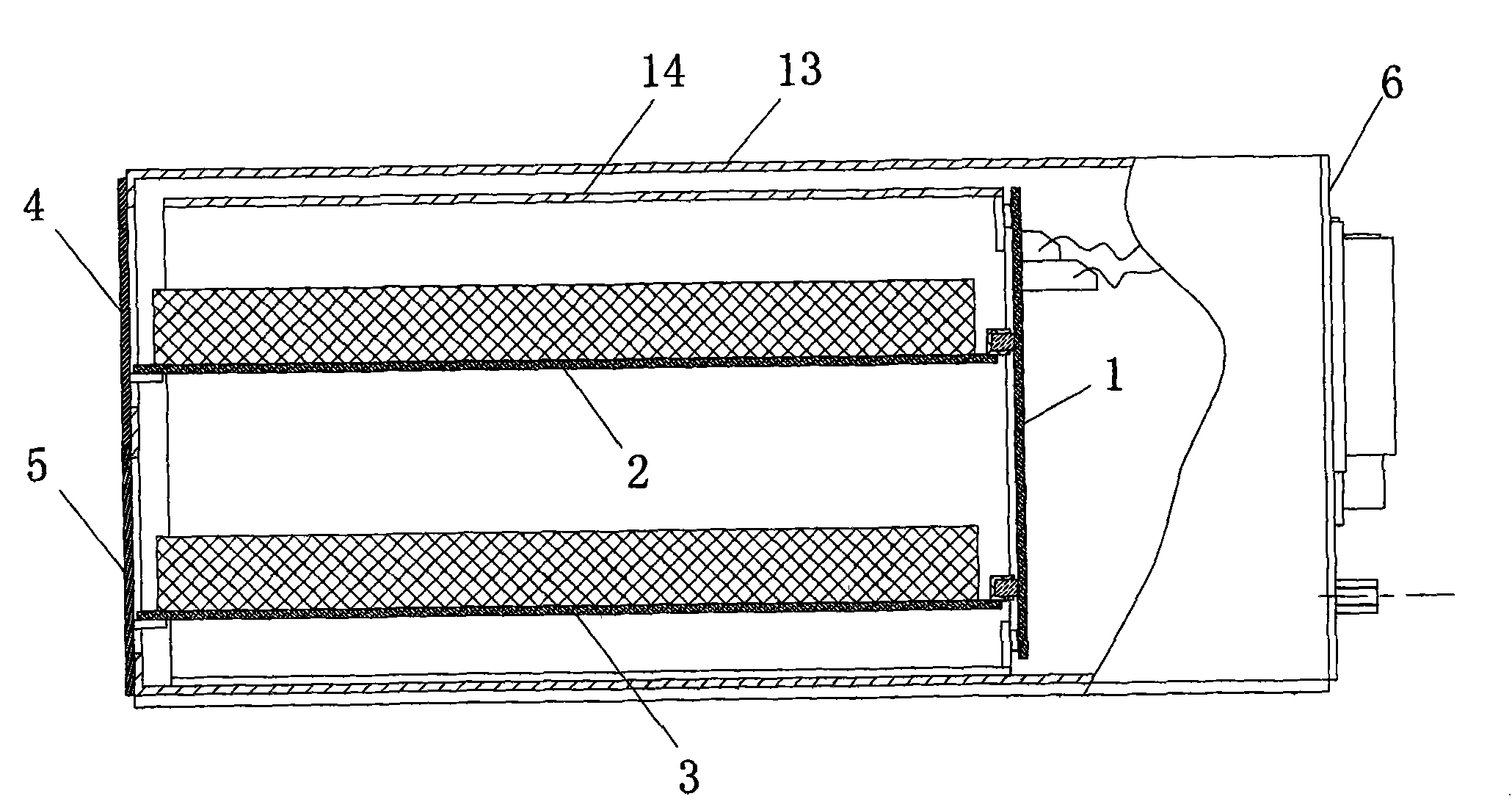

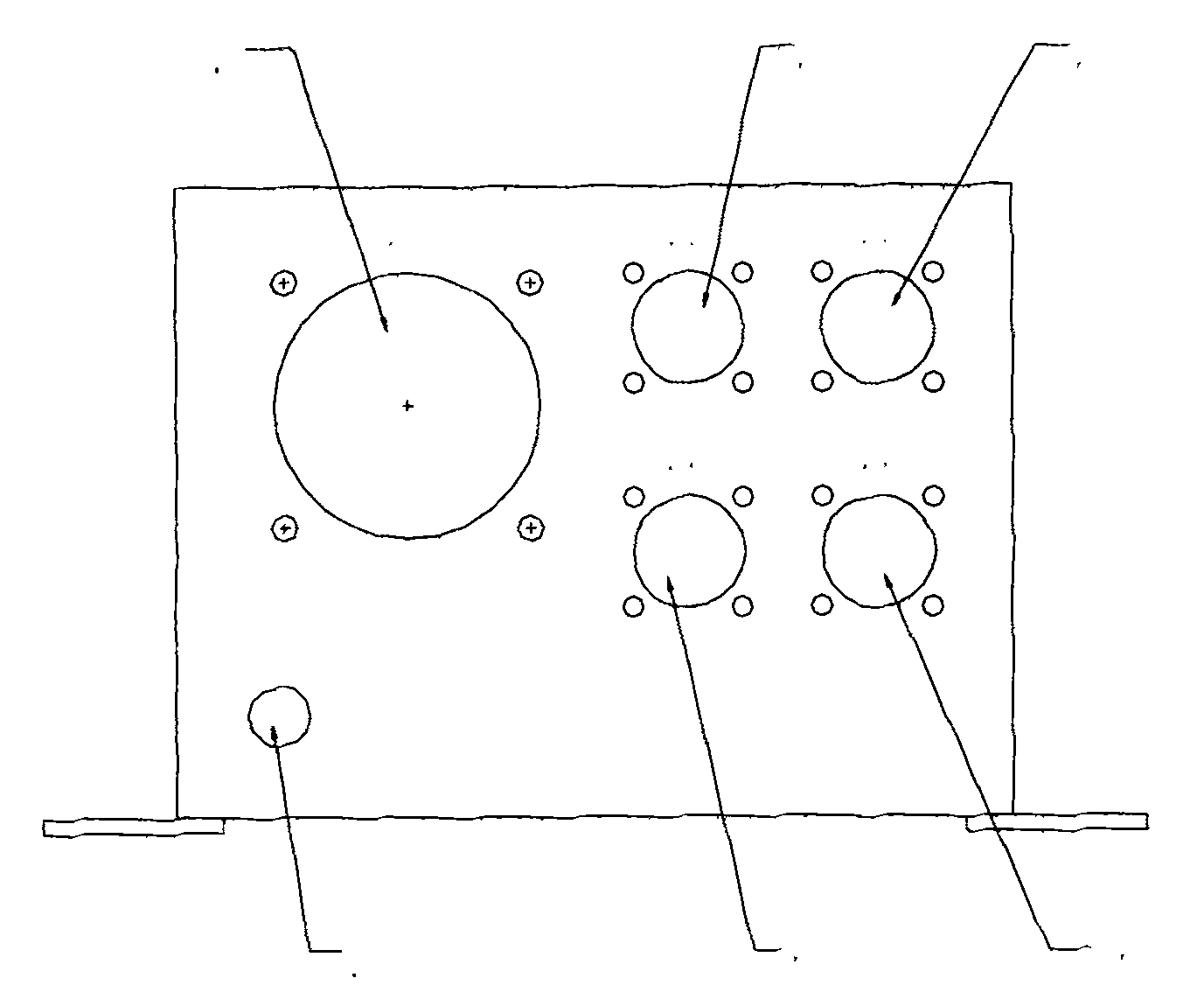

[0063] Such as figure 2 As shown, the signal processor is provided with a circuit connection seat board 1 and two main control circuit boards 2, 3, the circuit connection seat board 1 is respectively circuit connected with the two main control circuit boards 2, 3, and the front end of the signal processor is provided with There are two display and operation panels 4, 5, and the two display and operation panels 4, 5 are respectively connected to the two main control circuit boards 2, 3 circuits; the rear end of the signal processor is provided with an external connection socket 6, and the external connection socket 6 Connect the signal receiver; there are two signal indicator boards, which are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com