Processing method of multicolour concavo-convex panel

A processing method and concave-convex shape technology, applied in the direction of building components, buildings, ceilings, etc., can solve the problems of falling off process steps, poor color pattern strength, etc., and achieve the effect of reducing process steps, omitting high-temperature baking, and not being easily injured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Implement the processing method of the multi-color concave-convex panel of the present invention according to the following steps:

[0025] (1) Cutting, that is, to cut the metal sheet into the required shape specification to become a flat cut piece 1, such as figure 1 shown in order to further bend the edges into shape;

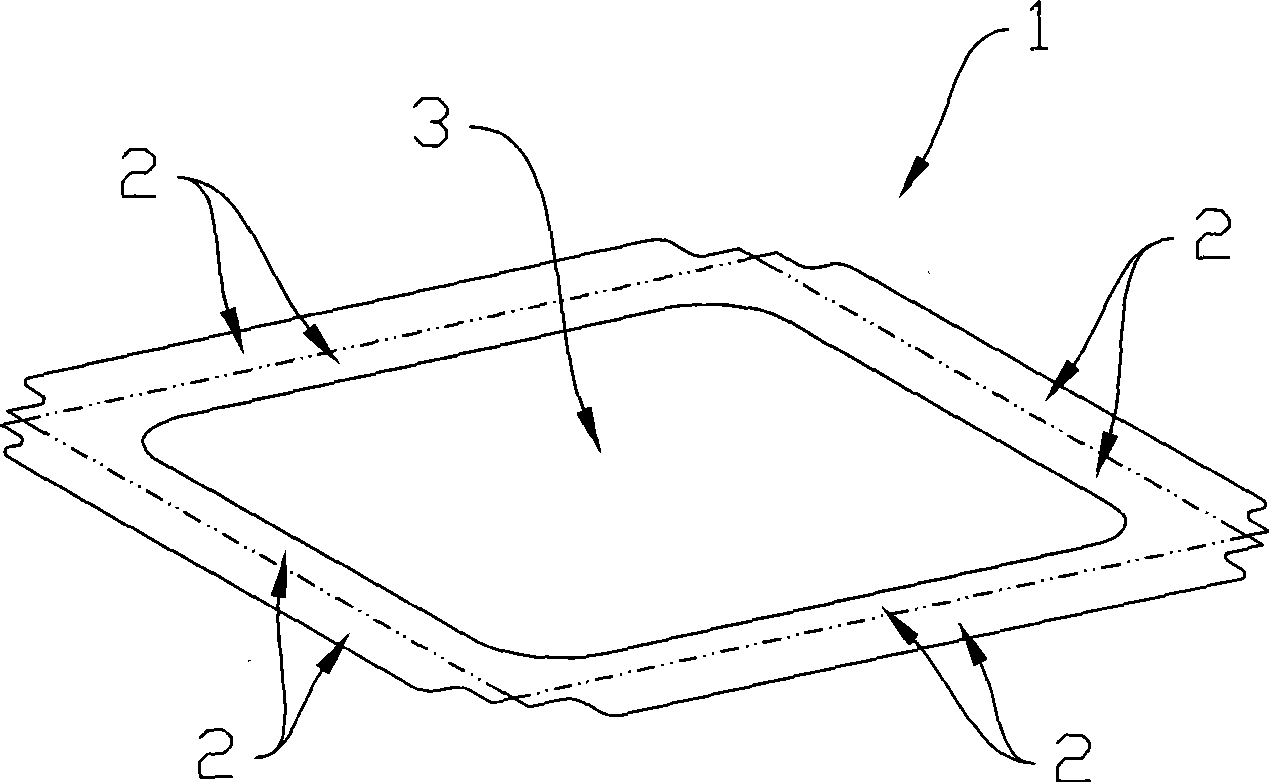

[0026] (2) Masking and oxidative coloring, that is, the uncolored area on the surface of the flat cut piece is covered with a mask, so that the pre-colored area is exposed for oxidative coloring (see figure 2 Masked area 2 and oxidized colored area 3) in

[0027] (3) remove the mask, and cover the protective film on the surface of the oxidized and colored flat cut piece;

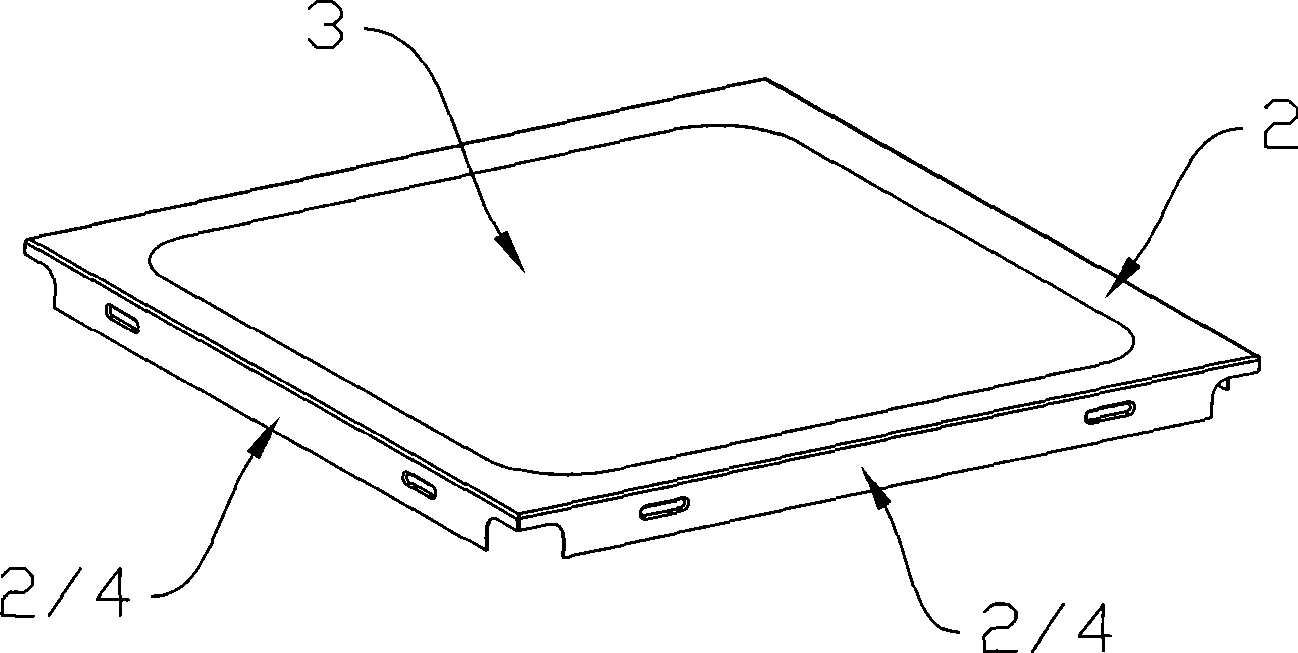

[0028] (4) Place the flat-shaped cut piece covered with the protective film on the mold for stamping, and the corresponding colored area forms a concave-convex shape (see Figure 4 The colored area 3 in the front is concave and the back is convex), and at the same time, the edge...

Embodiment 2

[0030] Implement the processing method of the multi-color concave-convex panel of the present invention according to the following steps:

[0031] (1) Cutting, that is, cutting the metal sheet into the required shape and specification as figure 1 the flat cutout 1 shown, and place the edge of the flat cutout 1 along the figure 1 The double-dot dash line in is folded into image 3 Hem 4 shown;

[0032] (2) Shading and oxidation coloring, about to image 3 The non-pigmented areas of the surface of the semi-finished product shown are masked off, thereby exposing the pre-pigmented areas for oxidative coloring (see image 3 Masked area 2 and oxidized colored area 3) in

[0033] (3) remove the mask, and cover the protective film on the surface of the oxidized and colored flat cut piece;

[0034] (4) Place the flat-shaped cut piece covered with the protective film on the mold for stamping, and the corresponding colored area forms a concave-convex shape (see Figure 4 The colore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com