Smooth and steady workstation of vertical lathe

A vertical lathe and workbench technology, applied in the field of lathes, can solve problems such as difficulty in ensuring the parallelism of tool holders and affecting the machining accuracy of workpieces, and achieve the effects of stable work, improved wear resistance, and high rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

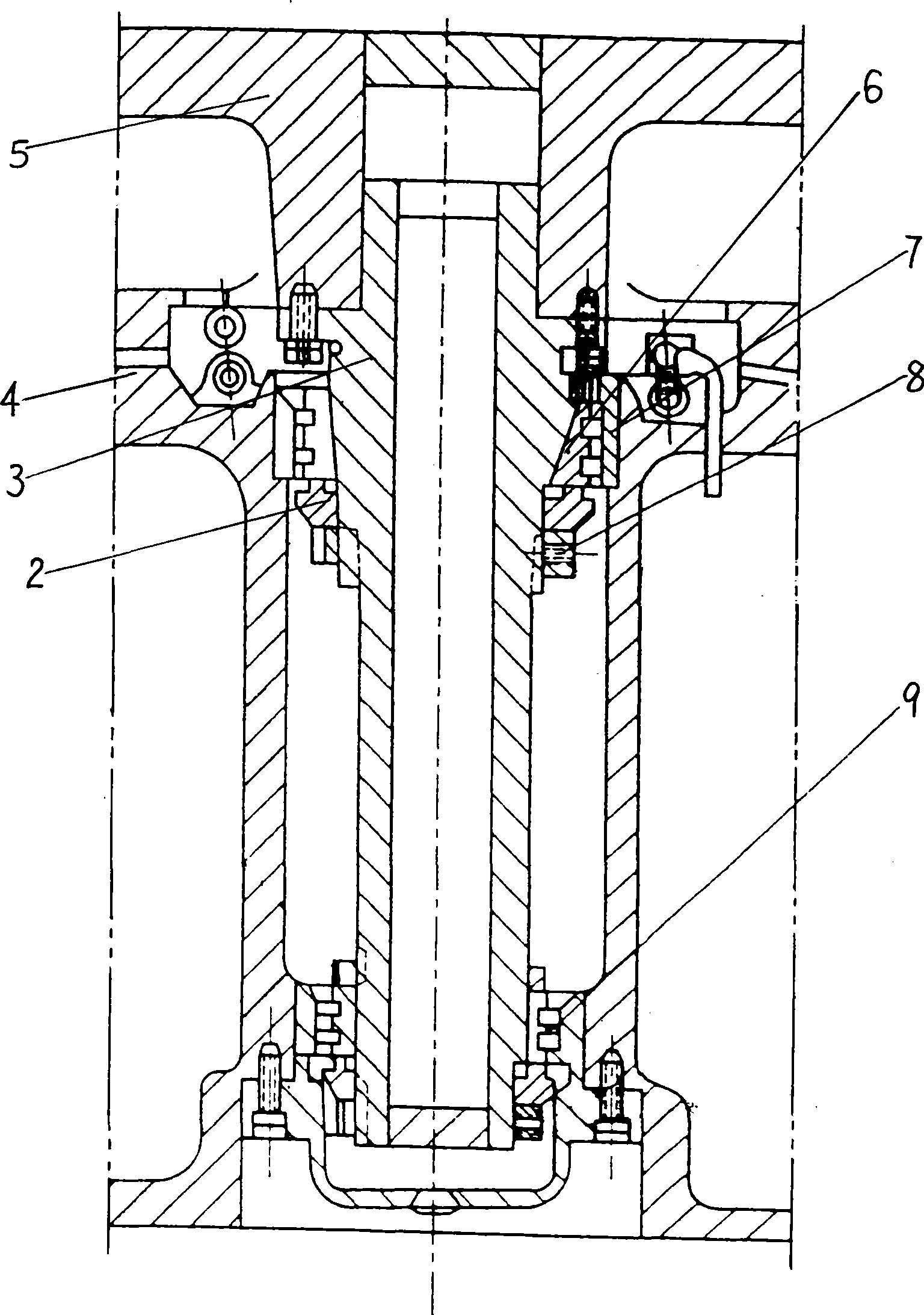

[0012] Such as figure 1 The vertical lathe workbench shown involves a turntable 5 and a base 4, and the bottom surface of the turntable 5 and the upper surface of the base 4 are compounded with a zinc alloy wear-resistant plate 1 to increase the service life of the workbench. The main shaft 3 is set in the base 4 through the bearing, the upper end of the main shaft 3 is fixedly connected with the turntable 5, the lower end of the main shaft is equipped with a bearing 9, the bottom end of the main shaft 3 is connected with the reducer, and the outer diameter of the joint between the main shaft 3 and the base 4 has a taper. 3182100 type double-row cylindrical roller bearing 7 with tapered inner ring 6 is installed at the place with taper. Adjusting nut 8 is set on the main shaft 3. The adjusting nut 8 is close to the small inner diameter end of bearing 7. Adjusting nut 8 and tapered bearing 7 Adjusting spacers 2 are installed between them.

[0013] When the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com