Case-making method of silicasol investment casting with elongated hole structure

A silica sol, slender hole technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of only suitable for large-scale products, high cost, long cycle, etc., to achieve flexible application, low cost, and short cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

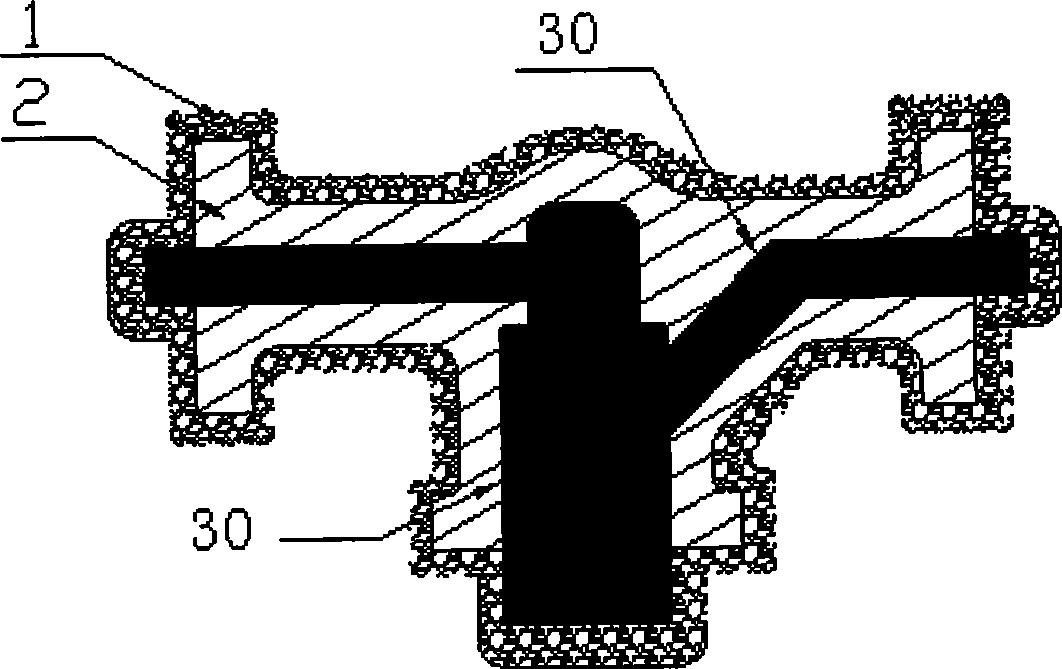

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

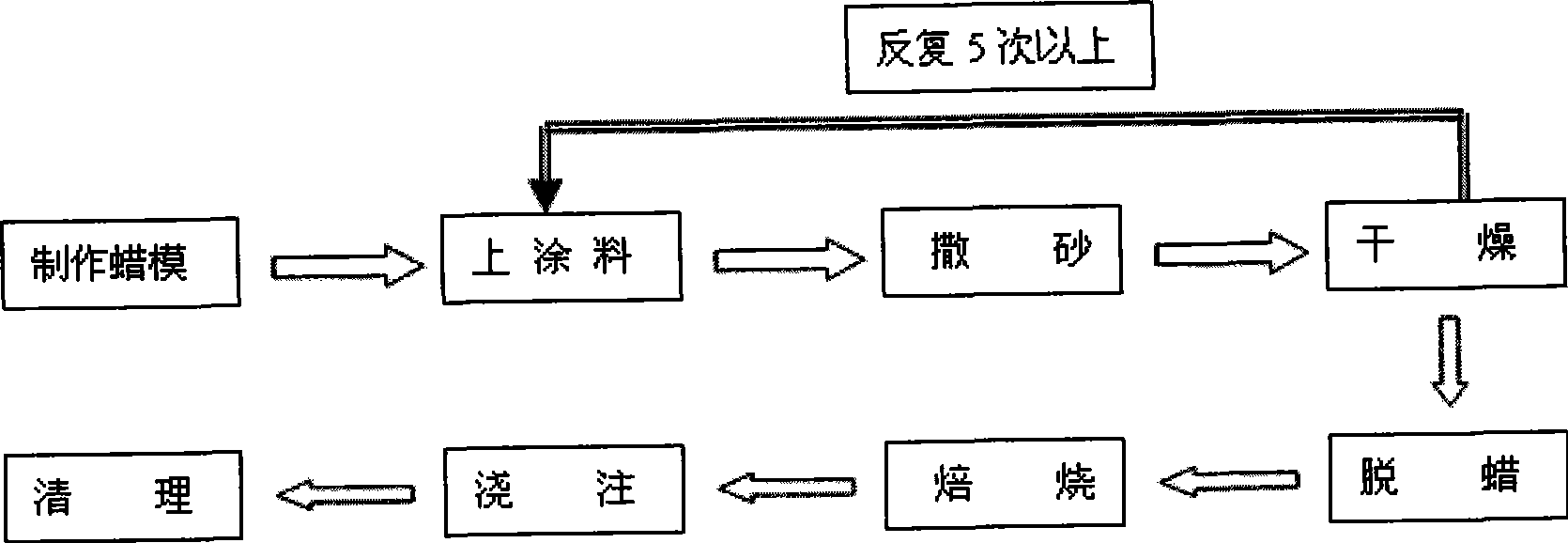

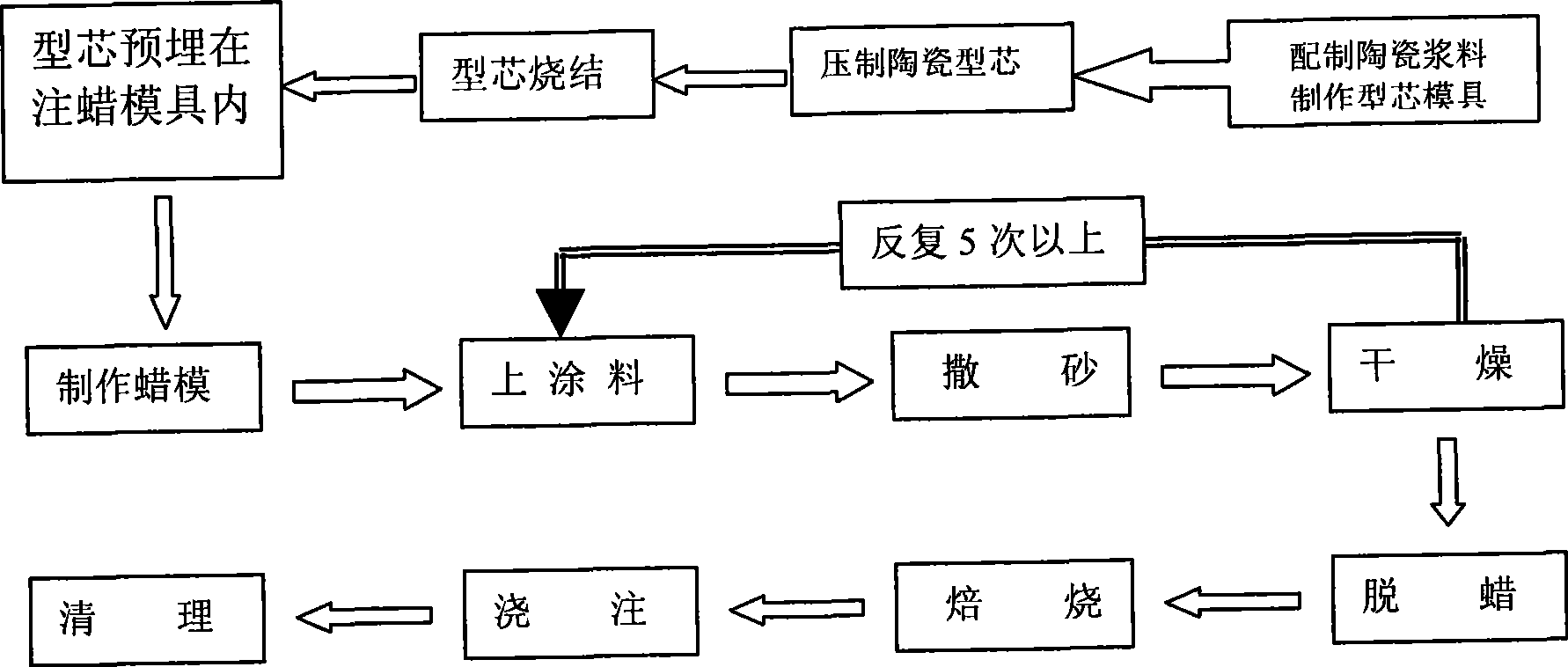

[0038] In order to solve the problems of the technologies described above, the present invention is achieved through the following steps (as Figure 4 shown):

[0039] 1. Make a wax model: use a general-purpose wax injection mold;

[0040] 2. Coating: dip the wax mold with silica sol zircon powder coating;

[0041] 3. Sanding: Sprinkle 100-120 mesh zircon sand on the whole wax model;

[0042] 4. Drying: the module is dried for 2-4 hours;

[0043] The number of times used between steps "2" to "4" is 2-3 times;

[0044] 5. Grouting in the hole;

[0045] 6. Continue to make the shell: after the grouting is completed and the slurry is hardened, make another 2-3 layers of shells;

[0046] 7. Dewaxing: After the shell making is completed, dewax to obtain the mold shell;

[0047] 8. Roasting and pouring;

[0048] where in step "5":

[0049] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com