Substitute material for repairing articular cartilage and preparation method

A technology of articular cartilage and material body, applied in medical science, prosthesis, etc., can solve the problems of easy wear, aging failure, unsatisfactory performance and use effect of silicone rubber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

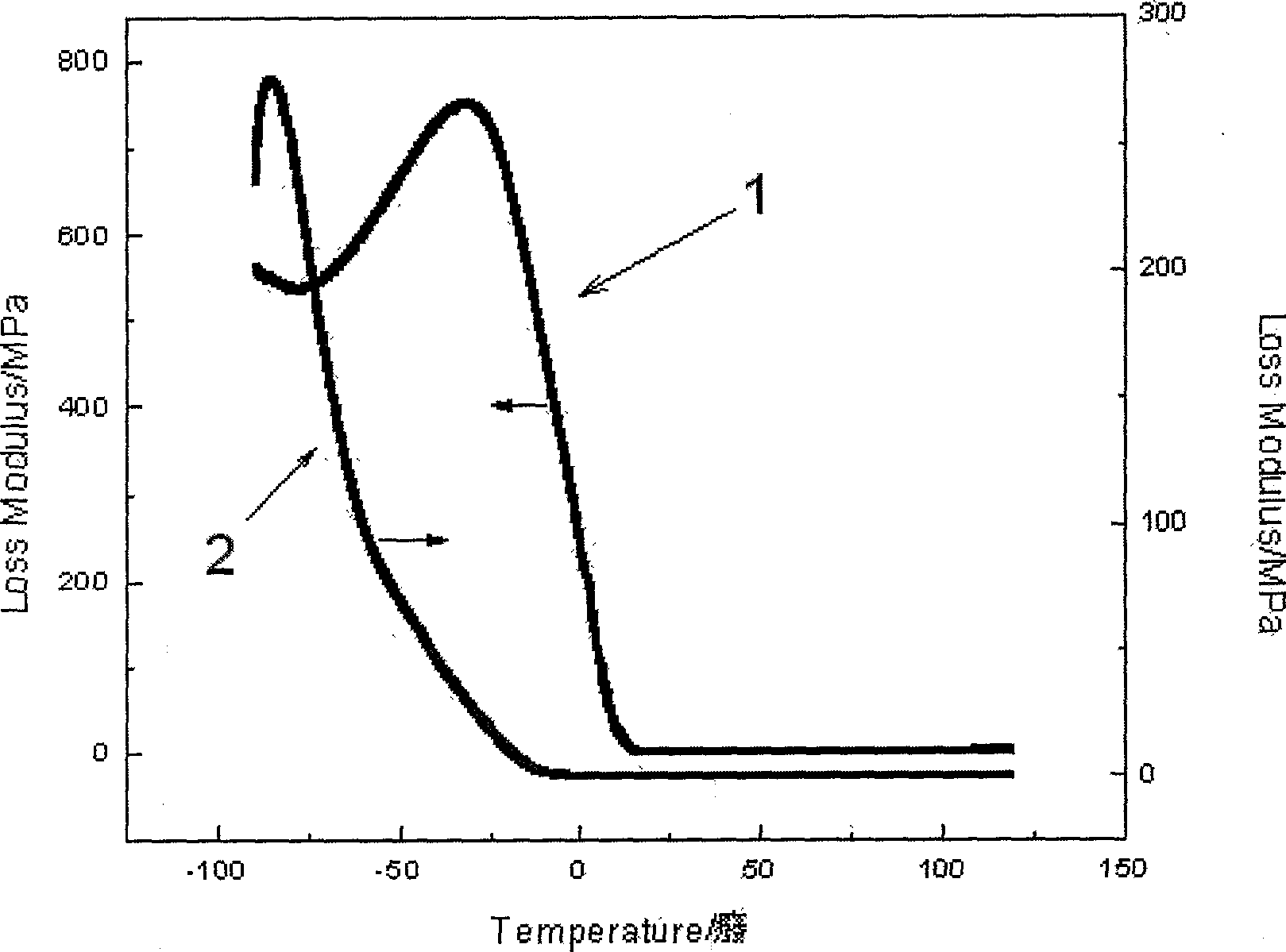

AI Technical Summary

Problems solved by technology

Method used

Image

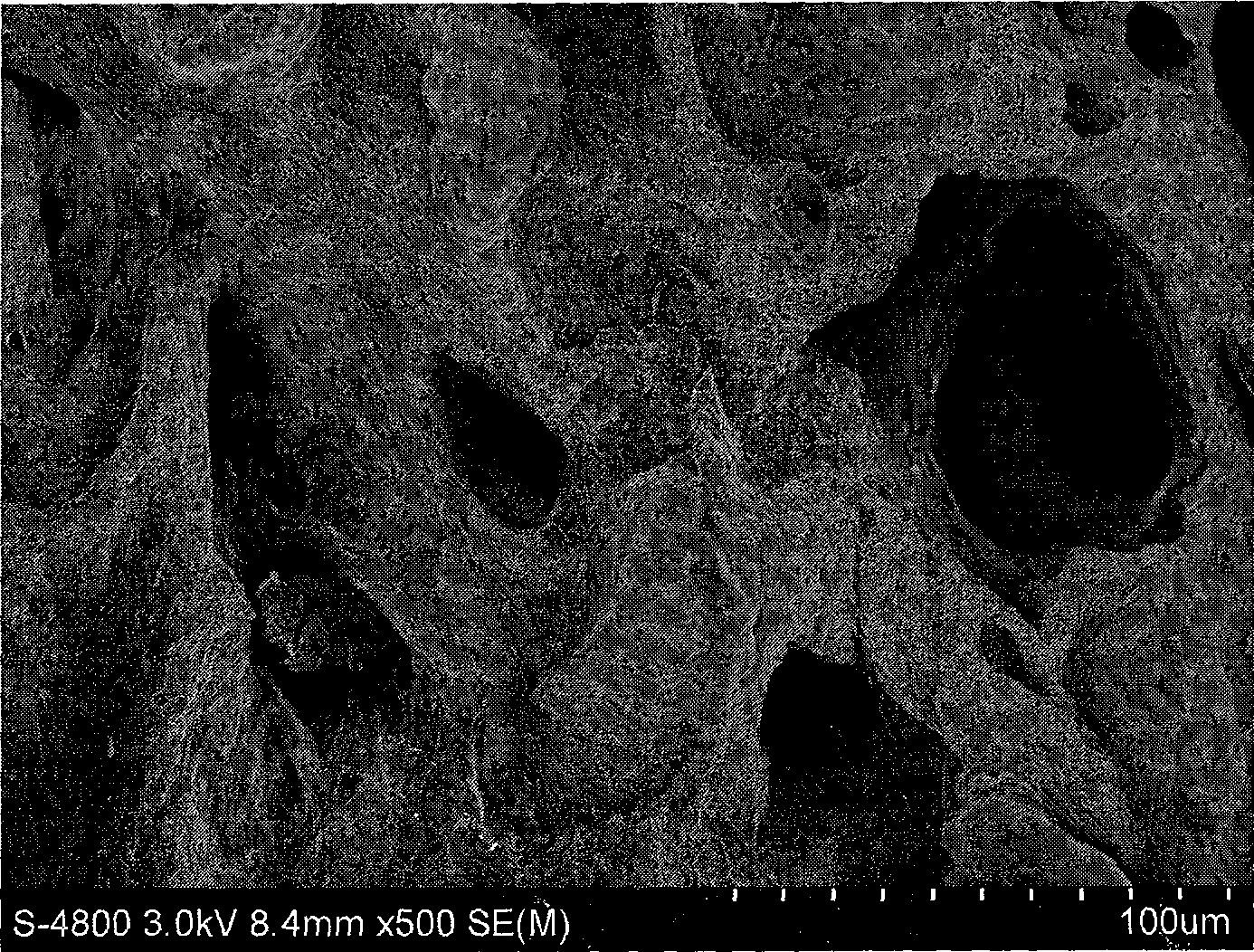

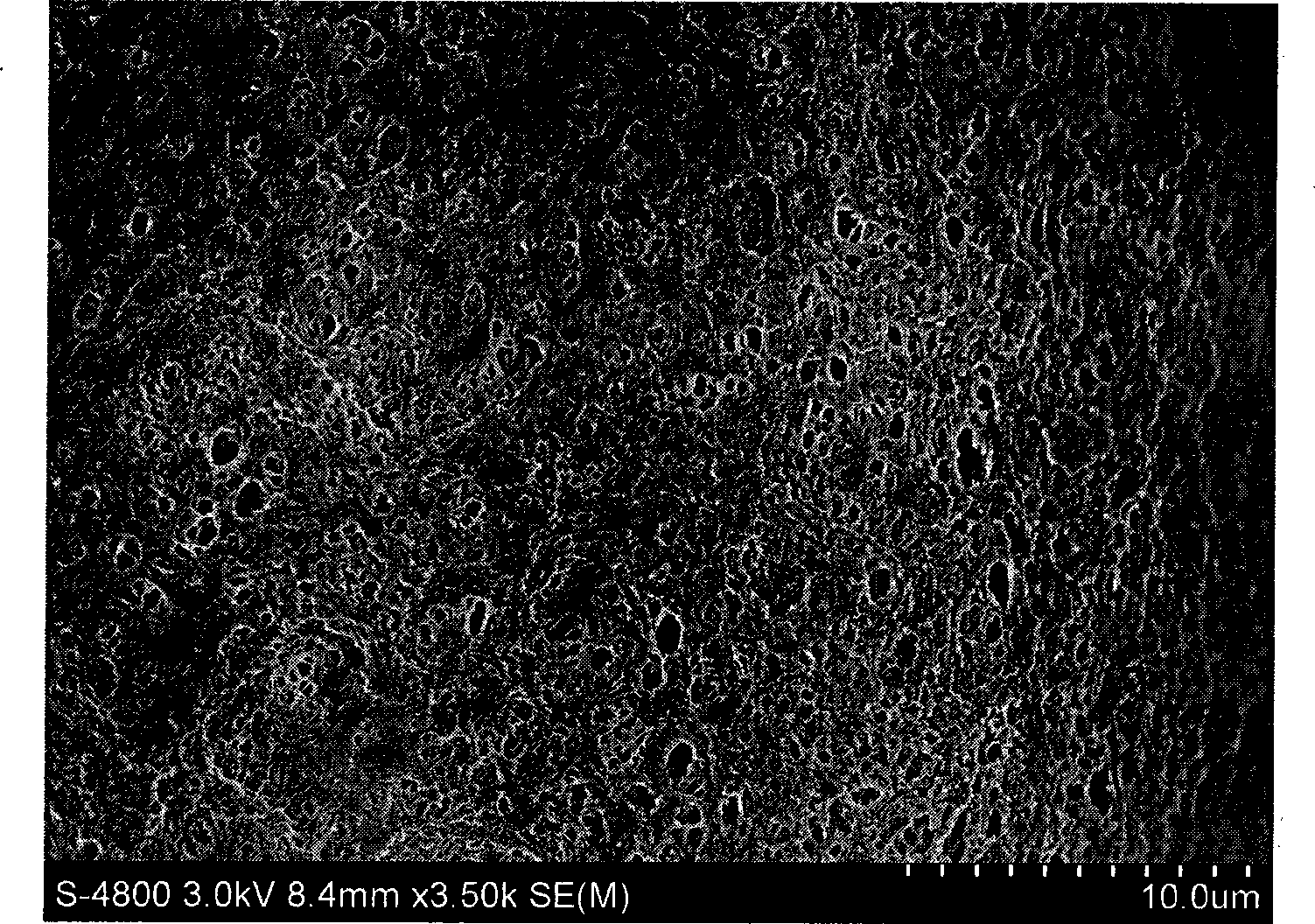

Examples

Embodiment 1

[0027] Take by weighing 30g polyvinyl alcohol (PVA) and add 170g water / dimethylsulfoxide mixed solvent (H 2 O / DMSO weight ratio 1 / 2), after ultrasonic dispersion for 40 min, fully dissolved in a water bath at 95°C to obtain a 15% PVA solution. Weigh 30g of N-vinylpyrrolidone (NVP) and dissolve it in PVA solution, drop the temperature to 40-50°C and maintain this temperature, pass into nitrogen protection, add 1g of hydrogen peroxide with a mass fraction of 30% as initiator, 1g of mass fraction Ammonia water with a fraction of 25% is used as an activator, the pH of the mixed solution is adjusted to 7-8, and the reaction is stirred at 800 rpm for 1-2 hours until the temperature of the mixed solution rises and then decreases. Then add 1.5g of N,N-methylenebisacrylamide cross-linking agent, stir at 800 rpm for 10 minutes, let it stand for defoaming, freeze at -30°C for 12 hours, and then take it out at room temperature at 20°C Thaw for 4 hours, repeat the operation 7 times, soak ...

Embodiment 2

[0032] Weigh 30g of PVA and add 170g of deionized water, after ultrasonic dispersion for 40min, fully dissolve in a water bath at 95°C to form a 15% PVA solution. Weigh 20g of NVP and dissolve it in PVA solution when the temperature drops to 40-50°C, keep the temperature constant, pass through nitrogen protection, add 8g of hydrogen peroxide with a mass fraction of 30% as an initiator, and 10g of a mass fraction of 25% ammonia as a Activator, adjust the pH of the mixed solution to 8-9, stir and react at 800 rpm for 1-2 hours, until the temperature of the mixed solution rises and then decreases. Then add 1.5g of N,N-methylenebisacrylamide, stir at 700 rpm for 10 minutes, let stand to defoam, freeze at -30°C for 12 hours, then take it out and thaw at room temperature for 4 hours at 20°C. Repeat the operation 7 times, soak and rinse with water to remove unreacted cross-linking agent.

Embodiment 3

[0034] Weigh 30g of PVA and add 170g of dimethyl sulfoxide, after ultrasonic dispersion for 40min, fully dissolve in a water bath at 95°C to form a 15% PVA solution. Weigh 10g of NVP and dissolve it in PVA solution when the temperature drops to 70°C, keep the temperature constant, pass through nitrogen protection, add 3g of hydrogen peroxide with a mass fraction of 30% as an initiator, and 5g of ammonia with a mass fraction of 25% as an activator , adjust the pH of the mixed solution to be 7-9, stir and react at a speed of 800 rpm for 1-2h, until the temperature of the mixed solution increases and then decreases. Then add 1.5g of N,N-methylenebisacrylamide, stir at 1000 rpm for 10 minutes, let stand to defoam, freeze at -30°C for 12 hours, then take it out and thaw at room temperature 20°C for 4 hours. Repeat the operation 7 times, soak and rinse with water to remove dimethyl sulfoxide and unreacted cross-linking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com