Torsion and/or tension and/or pressure textile sensor

A technology of pressure sensors and sensors, applied in the direction of instruments, measuring force, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

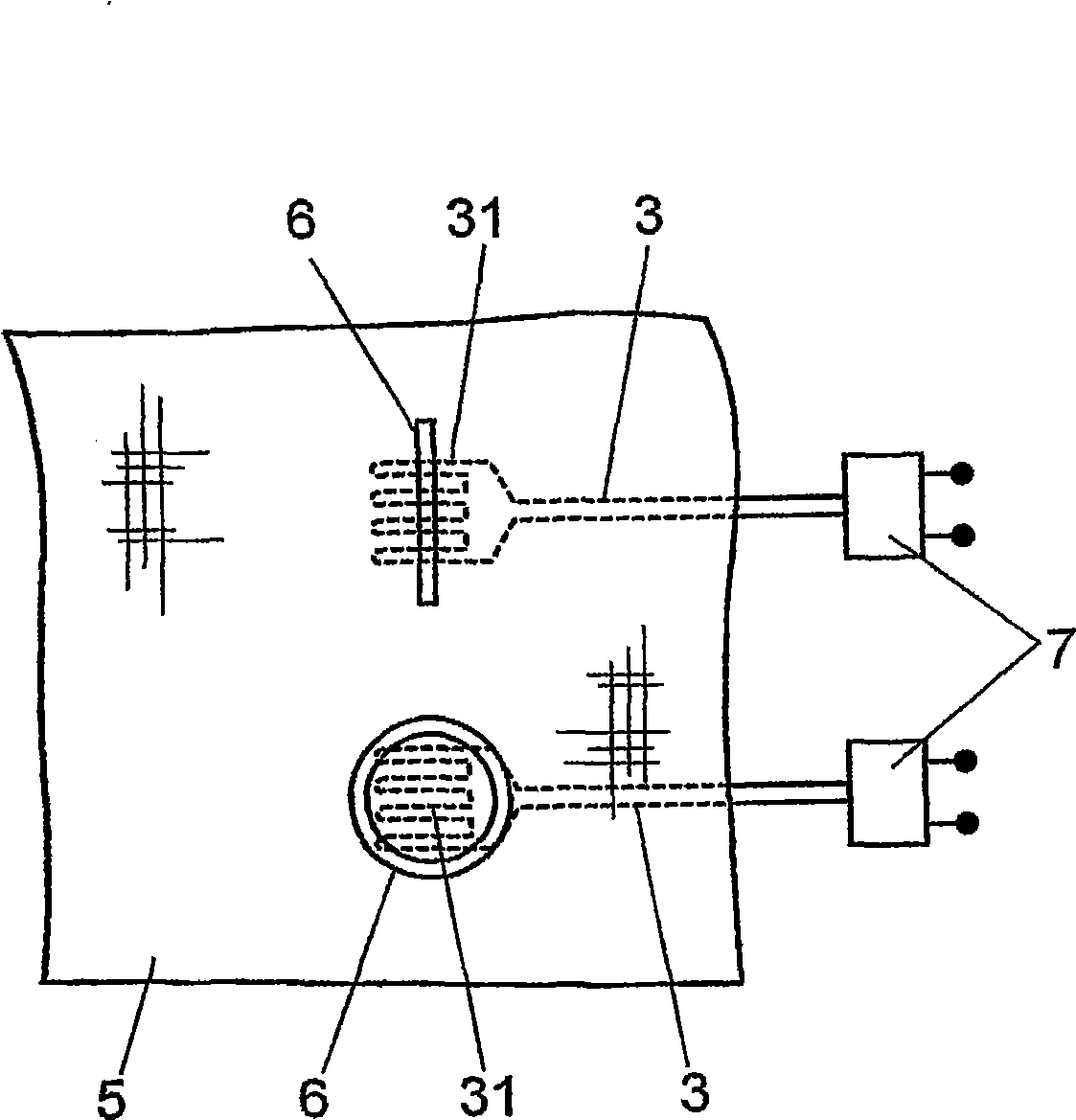

[0042] As can be seen in the attached figure, the textile sensor is built as a laminate-like structure consisting of:

[0043] - A base fabric layer (1) forming one of the outer surfaces of the sensor.

[0044] - An optional surface treatment layer (2) to even out the fabric (1).

[0045] - a single layer of trace conductive layer (3), formed from a conductive fluid, with twisting and optional surface treatment (2) on the fabric layer (1) to conform each trace to a stress or activation zone (31), A stress-sensitive, electrically conductive layer is thus formed, and the tracks ( 3 ) are deposited on the textile layer ( 1 ) and optionally on the surface treatment ( 2 ), for example by digital embossing.

[0046] - An encapsulating and protective layer (4) on the conductive layer (3), such as thermoplastic reactive polymers applied in sheet form using temperature and pressure because of their adhesive properties.

[0047] - a signal converter (7) that converts into a digital si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com