Warp knitting terylene ginning velvet carpet and method of processing the same

A warp-knitted polyester and processing method technology, which is applied in the field of polyester fiber products, can solve the problems of poor flatness of the tufted suede surface, increased loss of raw and auxiliary materials, and increased manufacturing costs, and achieves easy cleaning, shortened production process, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

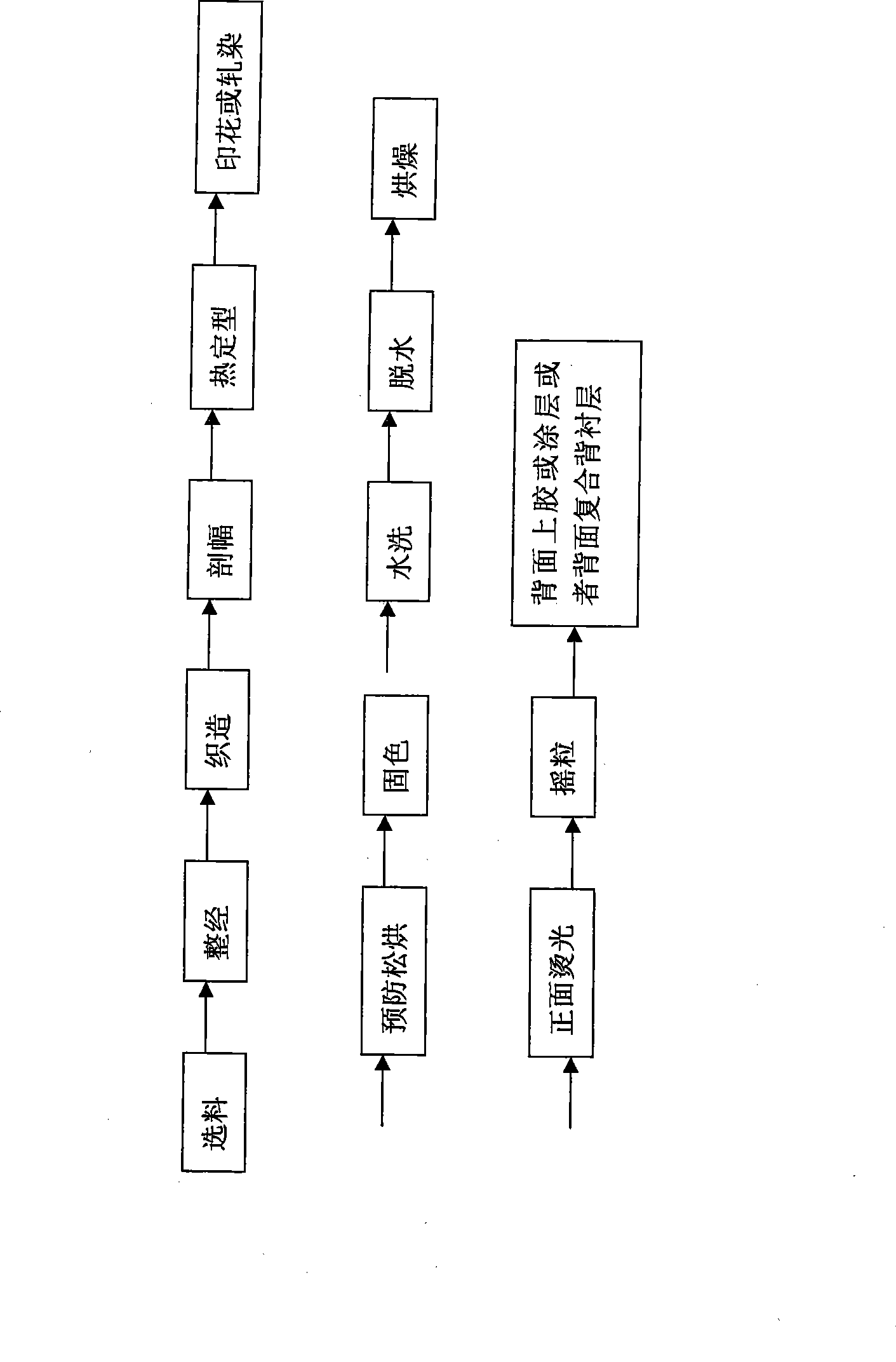

[0041]According to the technological process shown in the attached picture, the finished product specifications are suede with a height of 5.0mm and a weight of suede with a weight of 380g / m. 2 , Printed warp-knitted polyester velvet carpet with polyester coated back glue on the bottom.

[0042] A) material selection, choose 500dtex DTY silk with a monofilament size of ≥ 3.5dtex as the raw material of carpet pile yarn, choose 167dtex FDY silk as the carpet bottom yarn, that is, the bottom silk raw material, wherein the number of network points of the selected DTY silk is 80 / rice;

[0043] B) warping, warping the selected DTY silk and FDY silk with a warping machine;

[0044] C) Weaving, such as being produced by Changde Textile Machinery Co., Ltd., Changde City, Hunan Province, China, is the E-2281 type warp knitting machine weaving, through six bars of the warp knitting machine: GB1, GB2, GB5, GB6 produce the bottom layer AB For double-sided fabrics, GB3 and GB4 are laid b...

Embodiment 2

[0058] According to the technological process shown in the attached figure, the finished product specifications are 8.0mm in wool height and 600g / m in suede weight. 2 , The middle layer of sponge, the non-woven fabric of the base fabric is a sandwich-style and printed warp-knitted polyester grain pile carpet.

[0059] A) material selection, select the 667dtex DTY silk of ≥ 3.5dtex as the carpet pile yarn raw material, choose 222dtex FDY silk as the carpet bottom yarn (i.e. the bottom yarn) raw material, wherein, the number of network points of the selected DTY silk is 90 pieces / m;

[0060] B) warping, warping the selected DTY silk and FDY silk with a warping machine;

[0061] C) Weaving, such as being produced by Changde Textile Machinery Co., Ltd., Changde City, Hunan Province, China, is the E-2281 type warp knitting machine weaving, through six bars of the warp knitting machine: GB1, GB2, GB5, GB6 produce the bottom layer AB For the top fabric, GB3 and GB4 are laid back an...

Embodiment 3

[0075] According to the technological process shown in the attached figure, the finished product specifications are 12.0mm in wool height and 1000g / m in suede weight. 2 , Pile plain colored carpet with bottom coating structure.

[0076] A) material selection, select the 780dtexDTY silk with a monofilament size of ≥3.5dtex as the carpet pile yarn raw material, choose the 333dtex FDY silk as the carpet bottom yarn, that is, the bottom silk raw material, and wherein the number of network points of the selected DTY silk is 100 / rice;

[0077] B) warping, warping the selected DTY silk and FDY silk with a warping machine;

[0078] C) Weaving, such as being produced by Changde Textile Machinery Co., Ltd., Changde City, Hunan Province, China, is the E-2281 type warp knitting machine weaving, through six bars of the warp knitting machine: GB1, GB2, GB5, GB6 produce the bottom layer AB For the top fabric, GB3 and GB4 are laid back and forth in the AB surface fabric formed by the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com