Synchronous gear direct-drive gear apparatus for blast furnace bellless furnace top distributor

A technology of synchronous gears and transmissions, applied in the arrangement of clocks and funnels, etc., can solve the problems of limited torque transmission, unstable operation, and complicated mechanisms, and achieve the effects of reducing manufacturing difficulty, reducing production costs, and simple system configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Principle of the present invention, structure and specific implementation will be further described below in conjunction with accompanying drawing:

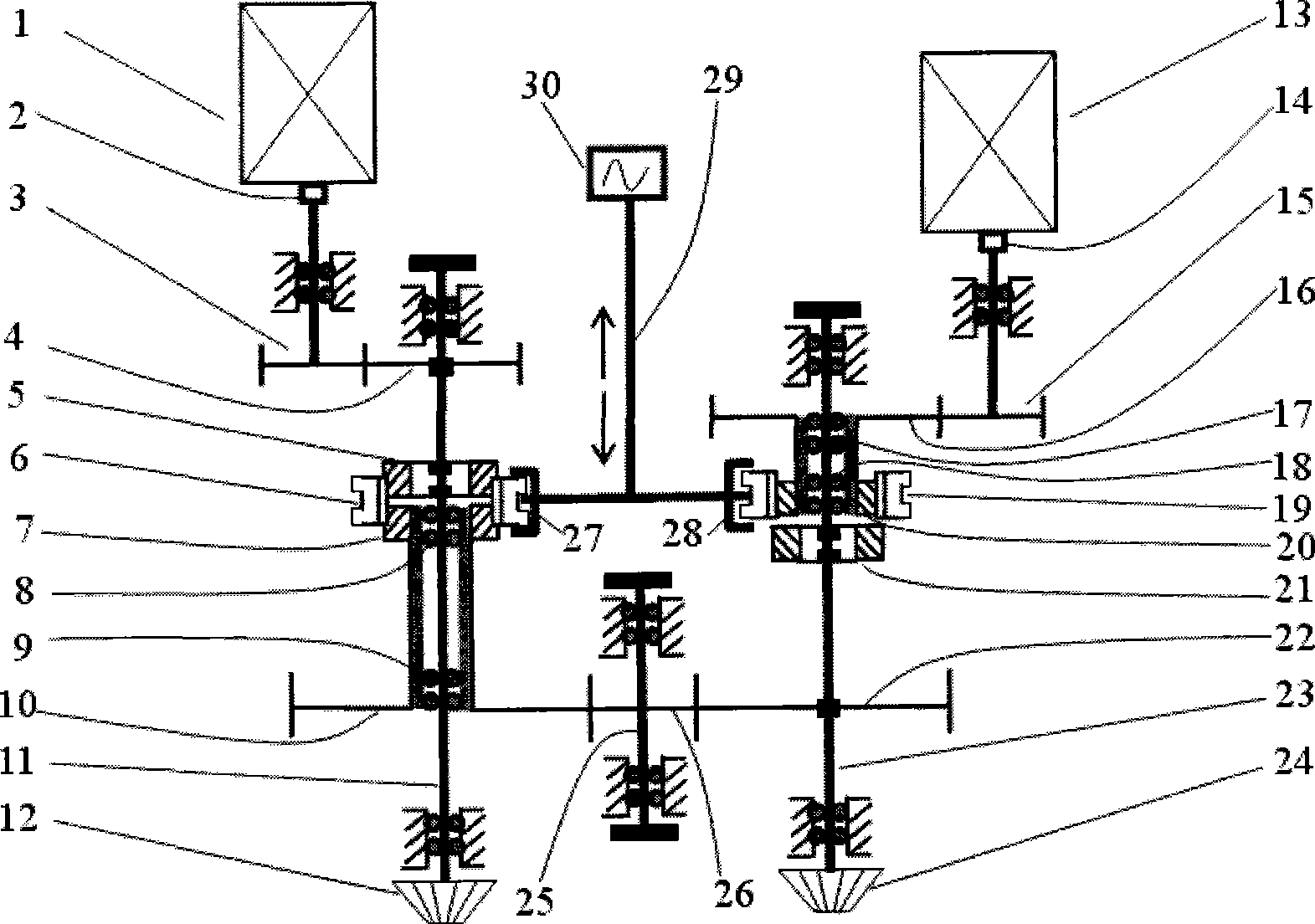

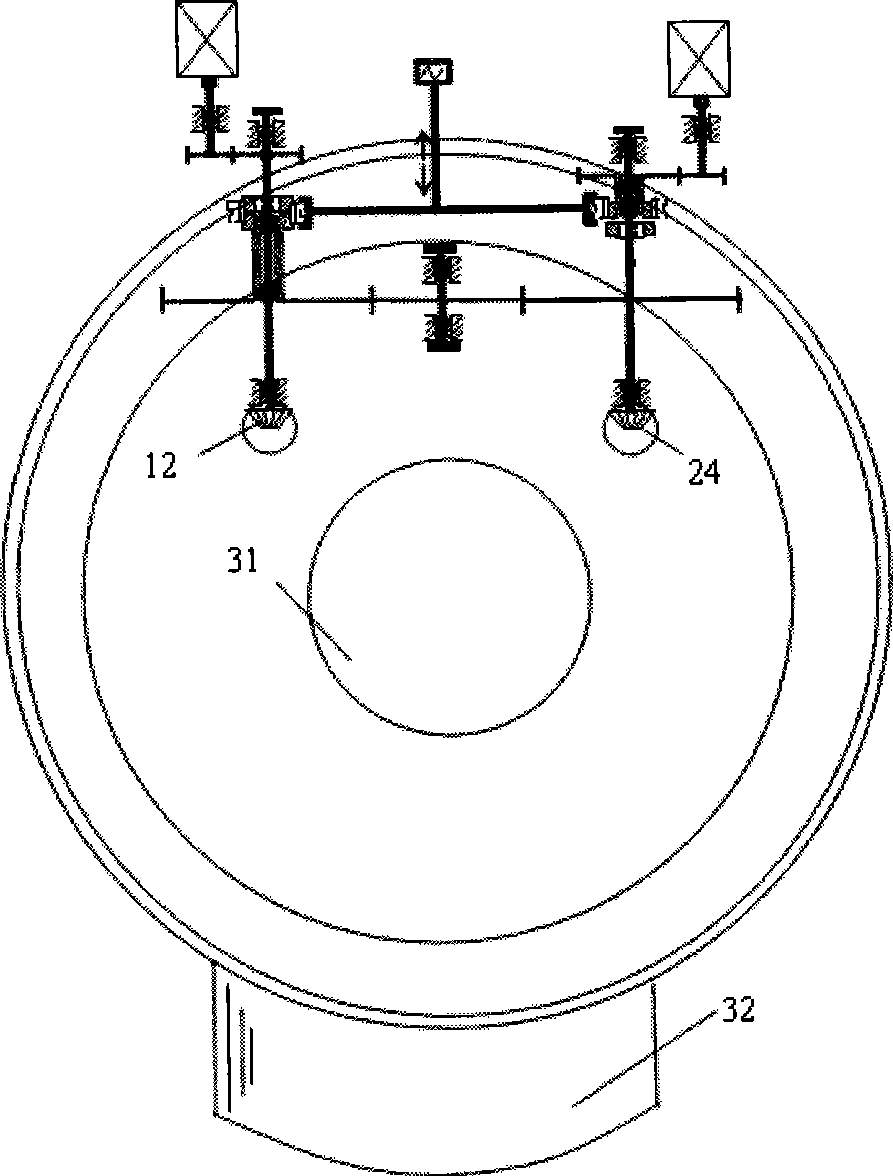

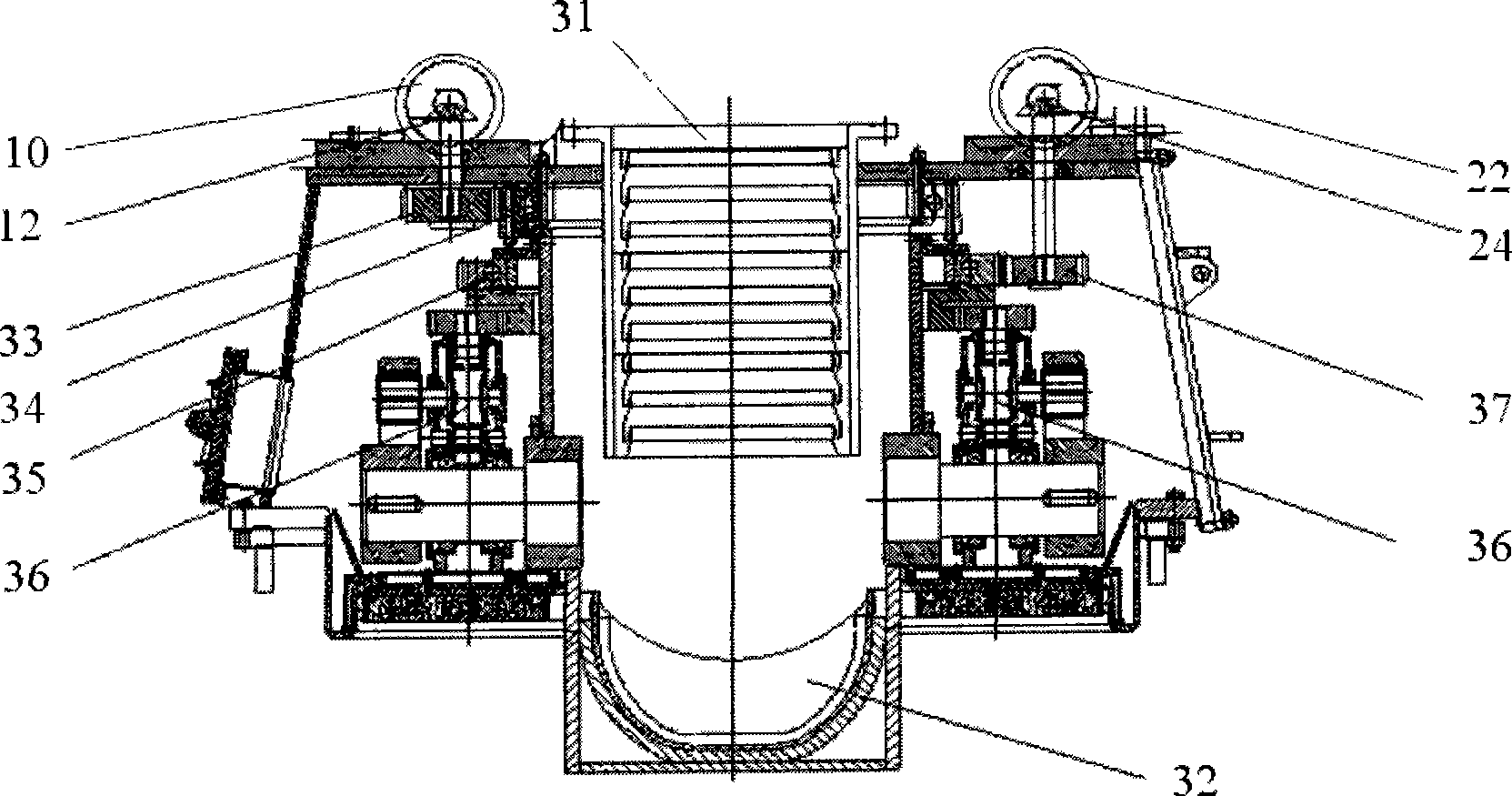

[0021] figure 1It is a structural schematic diagram of the synchronous gear direct transmission device provided by the present invention. The device comprises a main rotation motor 1, a main rotation reduction gear pair first gear 3, a main rotation reduction gear pair second gear 4, a main rotation drive shaft 11, a main rotation input gear 12, a tilting motor 13, a tilting reduction gear 15, The tilting drive shaft 23, the tilting input gear 24, the synchronous gear transmission mechanism arranged between the main rotating shaft and the tilting driving shaft, the main rotating gear sleeve engagement mechanism and the tilting gear set respectively on the main rotating shaft and the tilting driving shaft The meshing mechanism, and the fork mechanism that controls the meshing and separation; the synchronous gear transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com