Method for preparing large size yttrium system block material by Ag2O adding YBCO solder brazing

A brazing material and brazing technology, which is applied in the field of superconducting block material preparation, can solve the problems of slow crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

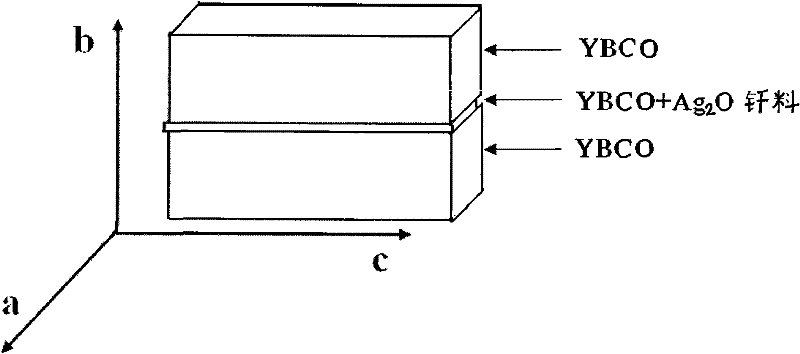

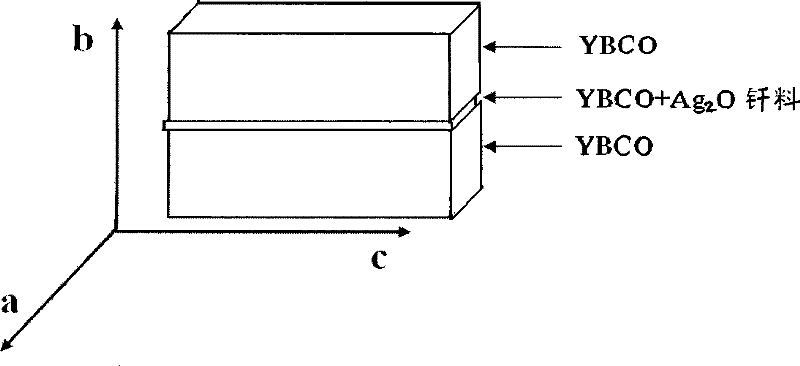

Image

Examples

Embodiment 1

[0019] Use to add Ag 2 O’s YBCO solder brazing method to prepare large-scale yttrium-based bulk materials, using the top seed crystal melt texture growth method to prepare the addition of Ag 2 The YBCO brazing material of 0 adopts the brazing connection process to weld the YBCO bulk material, and the method steps are as follows,

[0020] (1) Prepare and add Ag 2 O's YBCO solder:

[0021] ① Prepare Y-123 phase and Y-211 phase respectively by chemical synthesis method, Y-123 phase is YBa 2 Cu 3 Ox, the synthesis method is Y 2 o 3 、BaCO 3 , CuO mixed uniformly according to the nominal ratio, then sintered at 920°C for 48 hours, mixed again, and then sintered at 920°C for 48 hours; Y-211 phase is Y 2 BaCuO 5 , the synthesis method is Y 2 o 3 、BaCO 3 , CuO is mixed evenly according to the nominal ratio, then sintered at 930°C for 48 hours, mixed again, and then sintered at 930°C for 48 hours;

[0022] ②According to the weight ratio Y-123: 69.75%, Y-211: 20%, Ag 2 O: 10...

Embodiment 2

[0031] Use to add Ag 2 O’s YBCO solder brazing method to prepare large-scale yttrium-based bulk materials, using the top seed crystal melt texture growth method to prepare the addition of Ag 2 The YBCO brazing material of 0 adopts the brazing connection process to weld the YBCO bulk material, and the method steps are as follows,

[0032] (1) Prepare and add Ag2 O's YBCO solder:

[0033] ① Prepare Y-123 phase and Y-211 phase respectively by chemical synthesis method, Y-123 phase is YBa 2 Cu 3 Ox, the synthesis method is Y 2 o 3 、BaCO 3 , CuO mixed uniformly according to the nominal ratio, then sintered at 920°C for 48 hours, mixed again, and then sintered at 920°C for 48 hours; Y-211 phase is Y 2 BaCuO 5 , the synthesis method is Y 2 o 3 、BaCO 3 , CuO is mixed evenly according to the nominal ratio, then sintered at 930°C for 48 hours, mixed again, and then sintered at 930°C for 48 hours;

[0034] ②According to the weight ratio Y-123 phase: 49.5%, Y-211 phase: 30%, Ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com