Semi-conductive rubber, and preparation method and application thereof

A semi-conductive and rubber technology, which is applied in the field of semi-conductive rubber and its preparation, can solve the problems of reduced mechanical properties and electrical properties of the rubber compound, and the inability to meet the use conditions of the rubber compound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

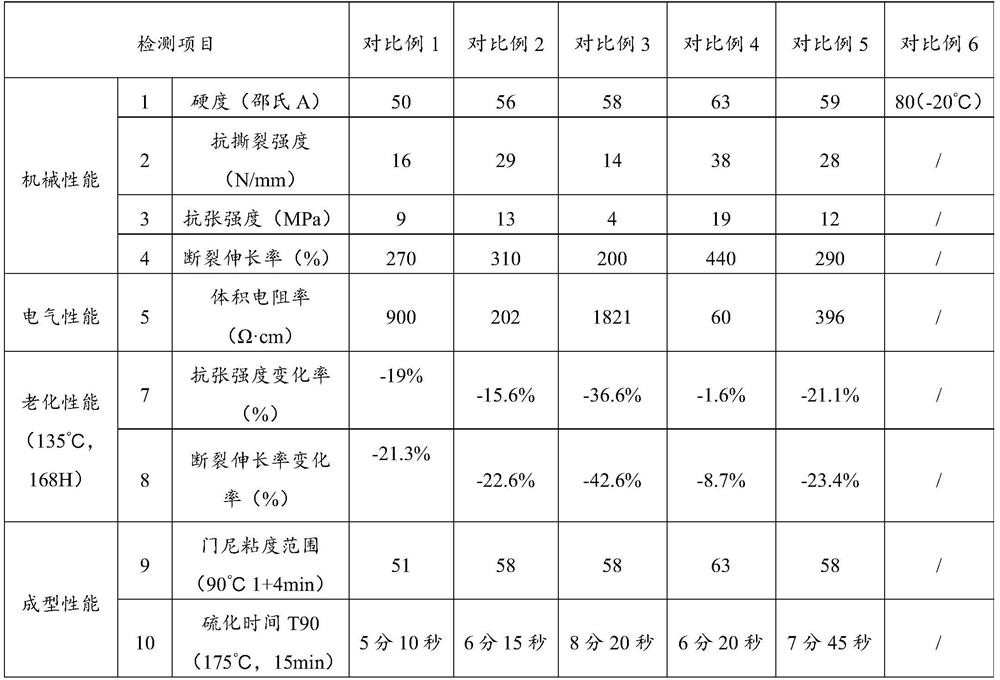

Examples

Embodiment 1

[0074] In this example, a semi-conductive rubber is prepared, and the specific preparation raw materials include:

[0075] EPDM rubber with grade 4520 of Dow Chemical: 100 parts;

[0077] Antiaging agent RD: 1 part;

[0078] Composite plasticizer: paraffin oil: 12 parts, dioctyl sebacate: 8 parts;

[0079] Superconducting carbon black: 28 parts;

[0080] Vulcanizing agent: dicumyl peroxide: 6 parts;

[0081] Composite auxiliary crosslinking agent: triallyl isocyanurate: 1.5 parts, sulfur: 0.5 parts.

[0082] Wherein, the superconducting carbon black is Czech AC-80 superconducting carbon black. In this embodiment, the added amount of superconducting carbon black is 17.4%.

[0083] The performance parameters of superconducting carbon black and ordinary carbon black are shown in Table 1.

[0084] Table 1

[0085]

[0086] The preparation method of the above-mentioned low-hardness, high-strength and high-electricity EPDM insulating rubber c...

Embodiment 2

[0093] This example adopts the same preparation method as in Example 1 to prepare a semiconductive rubber, and the specific preparation raw materials include:

[0094] EPDM rubber with grade 4520 of Dow Chemical: 100 parts;

[0096] Antiaging agent RD: 1 part;

[0097] Composite plasticizer: white naphthenic oil: 12 parts, polyisobutylene: 8 parts;

[0098] Carbon black: 30 parts;

[0099] Vulcanizing agent: dicumyl peroxide: 6 parts;

[0100] Composite auxiliary crosslinking agent: triallyl isocyanurate: 1.5 parts, sulfur: 0.5 parts.

[0101] Wherein, the superconducting carbon black is Czech AC-80 superconducting carbon black. In this embodiment, the added amount of superconducting carbon black is 18.4%.

Embodiment 3

[0103] This example adopts the same preparation method as in Example 1 to prepare a semiconductive rubber, and the specific preparation raw materials include:

[0104] EPDM rubber with grade 4520 of Dow Chemical: 100 parts;

[0106] Antiaging agent RD: 1 part;

[0107] Composite plasticizer: paraffin oil: 12 parts, dioctyl sebacate: 8 parts;

[0108] Superconducting carbon black: 28 parts;

[0109] Vulcanizing agent: di-tert-butyl peroxide: 7 parts;

[0110] Composite auxiliary crosslinking agent: triallyl isocyanurate: 2 parts, tetramethylthiuram disulfide: 2 parts.

[0111] Wherein, the superconducting carbon black is Czech AC-80 superconducting carbon black. In this embodiment, the superconducting carbon black is added in an amount of 17.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com