Method for preparing iso-temperature double-buffering layer of sapphire substrate

A sapphire substrate and double buffer layer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor growth quality of a single buffer layer, achieve reduced dislocation density, high room temperature mobility, and improved Effect of crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

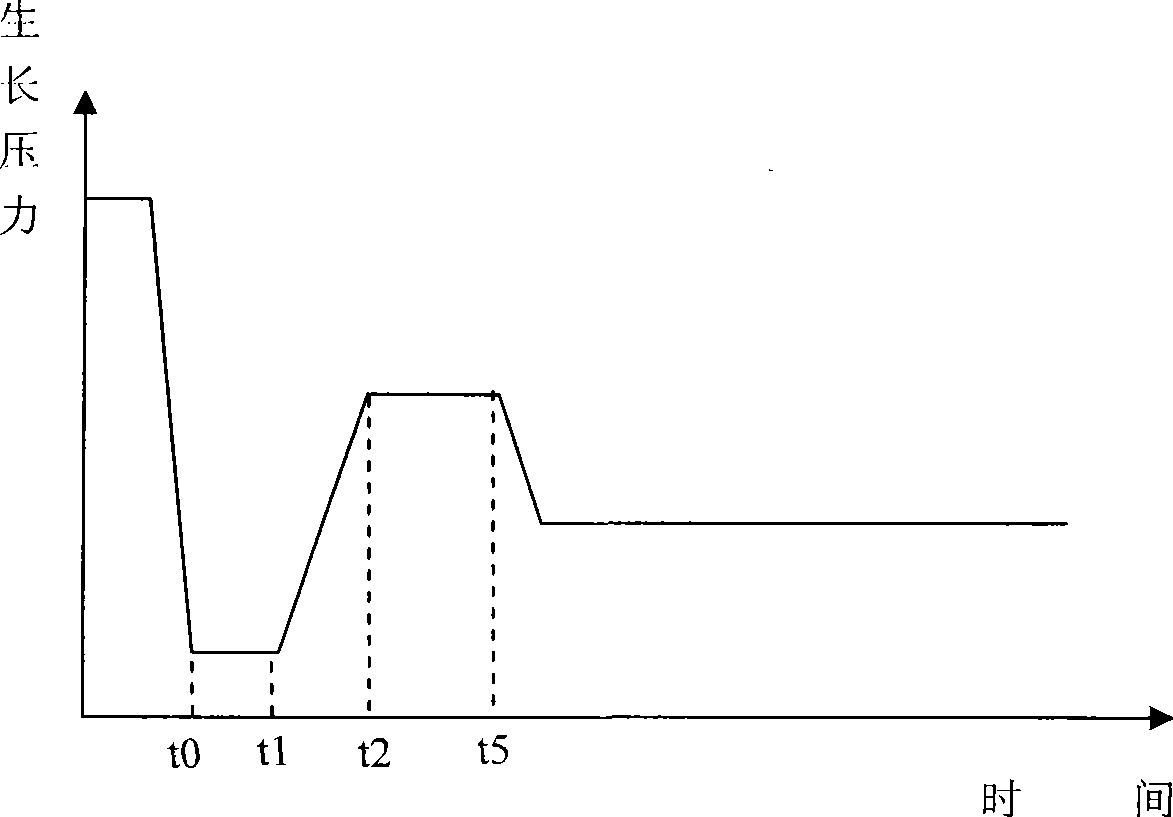

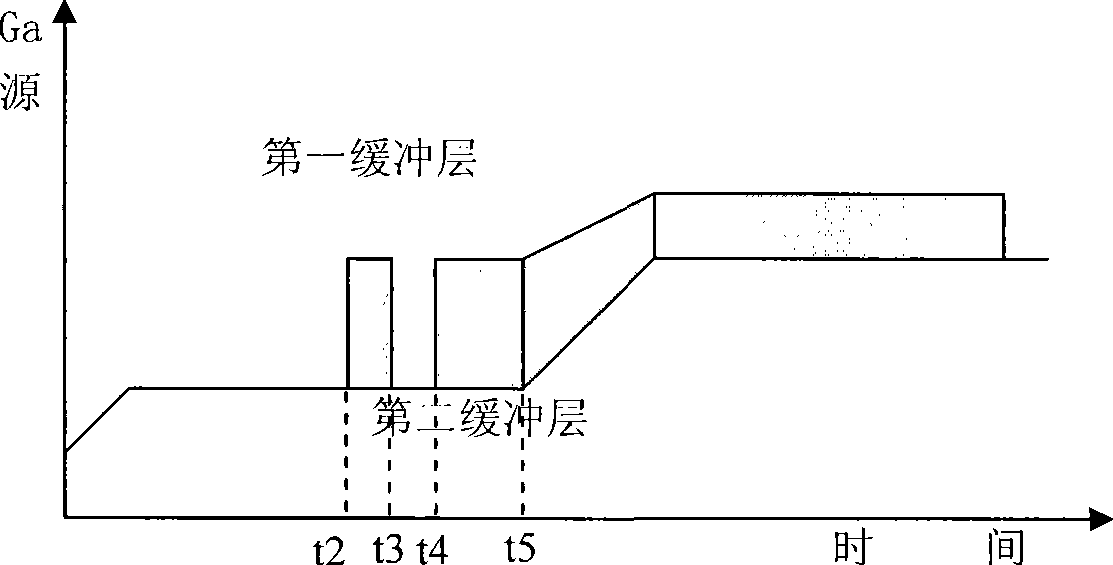

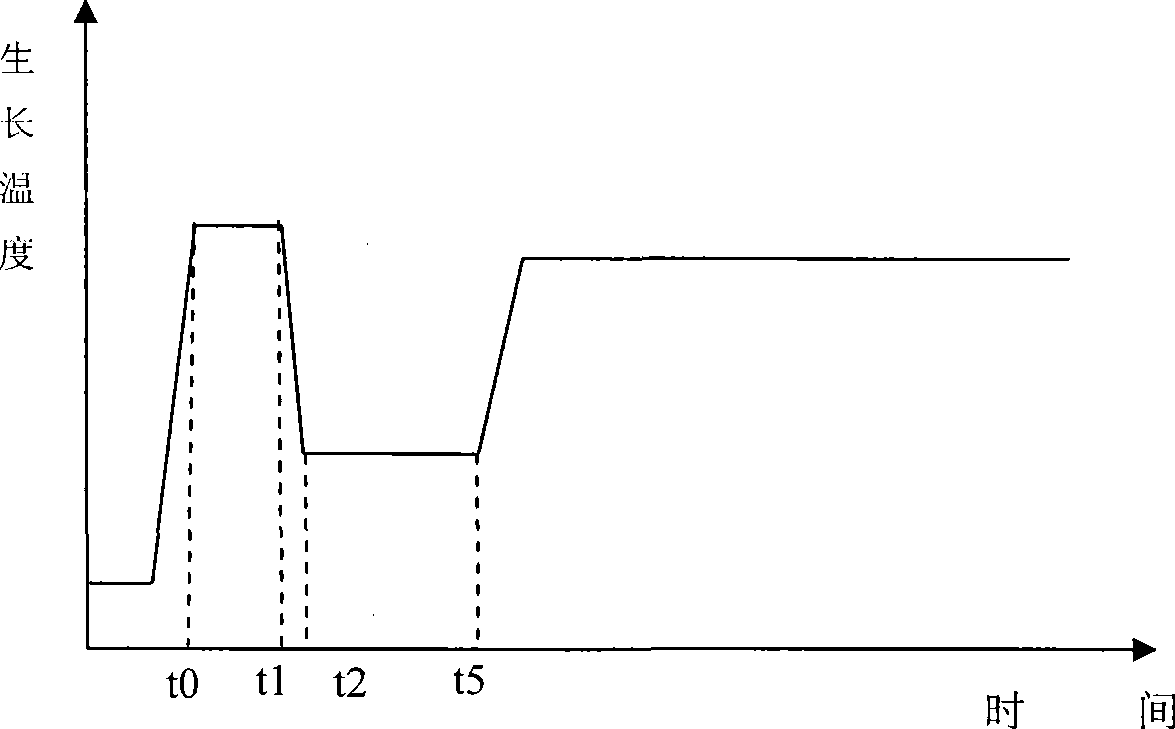

[0026] Such as Figure 1 to Figure 3 Shown is an embodiment of the same-temperature double-buffer layer preparation method for sapphire substrates of the present invention, which introduces low-temperature double-buffer layers with different thicknesses during the epitaxial growth of gallium nitride (GaN) by metalorganic chemical vapor deposition (MOCVD) process technology, in sapphire (Al 2 o 3 ) grow heterogeneous GaN crystals on the substrate, and improve the crystal quality of GaN grown on sapphire. The method mainly includes the following steps:

[0027] Open the vacuum package of the prepared sapphire substrate in the reaction chamber, put it directly into the graphite disk of the MOCVD equipment, and start the program. First, the sapphire substrate is cleaned and pretreated: the reaction chamber is heated to about 1100-1200° C., and the pressure is 100-300 Torr. In this embodiment, the temperature is 1100° C., and the pressure is 100 Torr; and the sapphire surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com