Primer composition and coated article

A technology of composition and primer layer, which is applied in coating, transportation and packaging, and thin material processing, etc., can solve the problems of insufficient weather resistance, improve transparency and weather resistance, improve water resistance, and have a good linear expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

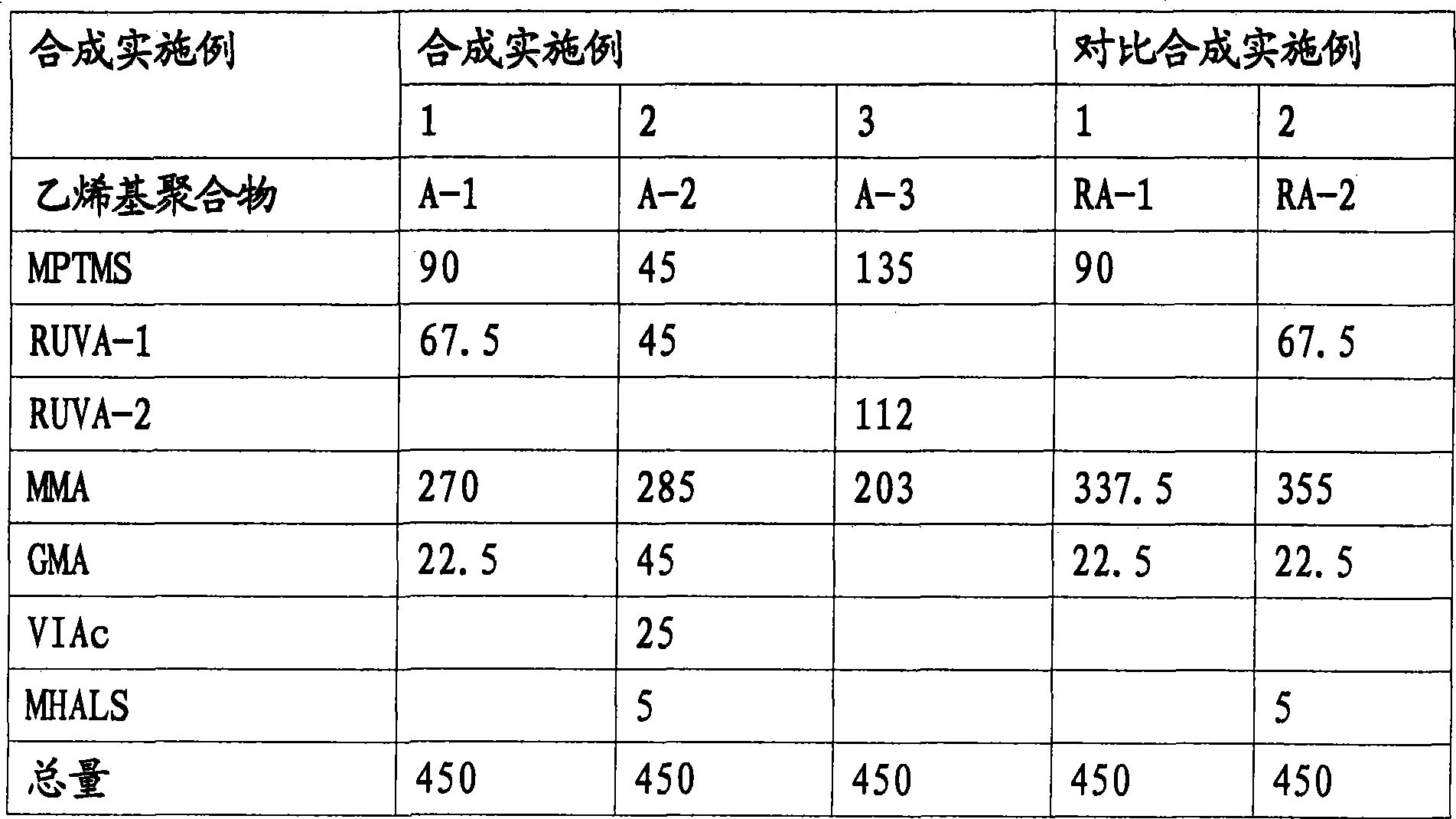

[0157] Synthesis Example 2,3 and Comparative Synthesis Example 1,2

[0158] Vinyl polymers, labeled A-2 and A-3, and comparative vinyl polymers, labeled RA-1 and RA-2 were prepared according to the formulation reported in Table 1 according to Synthesis Example 1.

[0159] [(B) Synthesis of organopolysiloxane]

[0160] Synthesis Example 4

[0161] A 2 liter flask equipped with a stirrer, condenser and thermometer was charged with 338 g of methyltrimethoxysilane and maintained at 20°C with stirring. 98 g of water-dispersed colloidal silica (Snowtex O with an average particle size of 15 to 20 nm, Nissan Chemical Industries Ltd., SiO 2 Concentration 20%) and 230 g of 0.25 N aqueous acetic acid solution were added to the flask, and the contents were stirred for 3 hours. Stirring was continued at 60° C. for a further 3 hours, after which 300 g of cyclohexanone were added and the by-product methanol was evaporated off at atmospheric pressure. Then 300 g of isopropanol and 134...

Embodiment 1 to 3 and comparative Embodiment 1 to 3

[0232] The primer composition was prepared as follows: the components were mixed according to the formulations (as solids) shown in Tables 2 and 3, and the above mixture was diluted to 10% with a mixed solvent of diacetone alcohol and propylene glycol monomethyl ether in a 20 / 80 weight ratio total solids concentration.

[0233] Each primer composition was applied to the clean surface of a 0.5 mm thick polycarbonate resin sheet (Iupilon Sheet of Mitsubishi Engineering-Plastics Corp) by dip coating, and then cured at 135° C. for 30 minutes to obtain A cured primer coat about 6 to 8 μm thick. To which a UV absorber (UVA-2 or 3), each of the colloidal silica-filled organopolysiloxane coating compositions prepared in Synthesis Examples 5 and 6 (HC-1 To 2), applied over the primer coating by dip coating method and then cured at 135°C for 1 hour to obtain a cured coating about 2 to 3 μm thick. The thus-obtained coated sheet, i.e., the sample, was examined by the above test. The te...

Embodiment 4 and 5

[0235] The primer composition was prepared as follows: according to the formula shown in Table 2 (as a solid basis), the components were mixed, and the above mixture was diluted to 10% of the total with a mixed solvent of diacetone alcohol and propylene glycol monomethyl ether in a 20 / 80 weight ratio. solid concentration. For the reaction of the vinyl polymer (A) with the organopolysiloxane (B), the resulting composition was heated at 60° C. for 3 hours, resulting in a composition containing the compound (C). The compositions thus obtained are used in coatings. Cured coatings and coating samples of the primer composition were prepared as in Examples 1 to 3, followed by the same tests. The results are also shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com