Preparation of fluoro-resin emulsion dipping agent and preparation of coated fabric

A technology of fluororesin emulsion and impregnating agent, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of resource waste, fluororesin coating burnout, and environmental impact, and achieve the effect of stable preparation process and easy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: The preparation method of the fluororesin emulsion impregnating agent of the present embodiment comprises the following steps:

[0038] ①Prefabricated A mixture, according to the following components and weight ratio:

[0039] 60% fluororesin emulsion 86.5% ~ 98.5%;

[0040] Coupling agent 0.5% to 5%;

[0041] Water-based silica latex with a pH value of 4-6 0.5%-7%;

[0042] FA-series fluorine-containing surfactants 0.5% to 3.5%;

[0043] Mix and stir the above-mentioned A mixture components evenly, A mixture components are stirred in a rotating container, the rotation speed is 60-90 rpm, and the stirring time is 2-5 hours, until there is no sinking and no condensation, stir The pH value of the final A mixture component is kept at 5-6, and then it is ready for use. Among them, the coupling agent is matched with the fluororesin emulsion, and the water-based silicone latex is soft and elastic, resistant to high temperature, and compatible with water;

[...

Embodiment 2

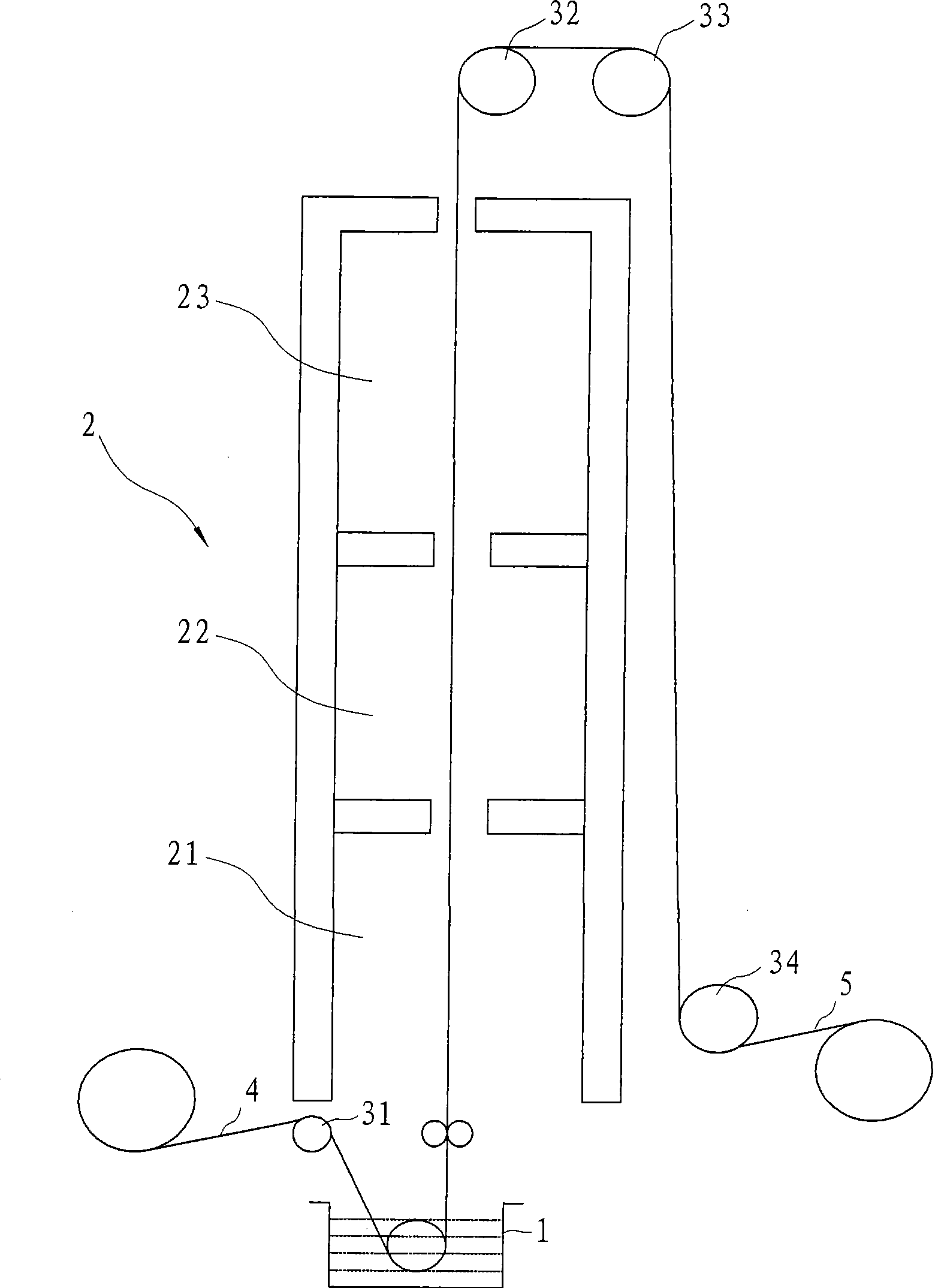

[0078] Example 2, such as figure 1 As shown, the coating equipment includes a dipping tank 1, a heat-fluid heat preservation body 2, and a drum 31, a drum 32, a drum 33, and a drum 34. A drying zone 21 , a second drying zone 22 and a sintering zone 23 .

[0079] The fabric cloth 4 passes through the impregnation tank 1 filled with impregnating agent through the drum drive, and then enters the heat-fluid insulation body 2, and first completes the first-stage drying in the first drying zone 21, and the condition is to dry at 80-120°C 2 to 5 minutes; then complete the second stage of drying in the second drying zone 22 under the condition of 200 to 300°C for 2 to 5 minutes; then complete sintering in the sintering zone 23 under the condition of 360 to 380°C After sintering for 2-5 minutes, the fluororesin-coated base cloth 5 is finally obtained, which has long-term heat resistance up to +260°C, no deformation, no shrinkage, no oil sticking, corrosion resistance, light weight, sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com