Preparation of foam magnesium alloy

A foamed magnesium alloy and magnesium alloy technology, applied in the field of alloy manufacturing, can solve the problems of poor comprehensive performance of porous foamed magnesium alloy, low porosity of foamed magnesium alloy, irregular shape of pores, etc., to improve flexibility and diversity The effect of uniformity, uniform distribution of pores, and regular shape of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

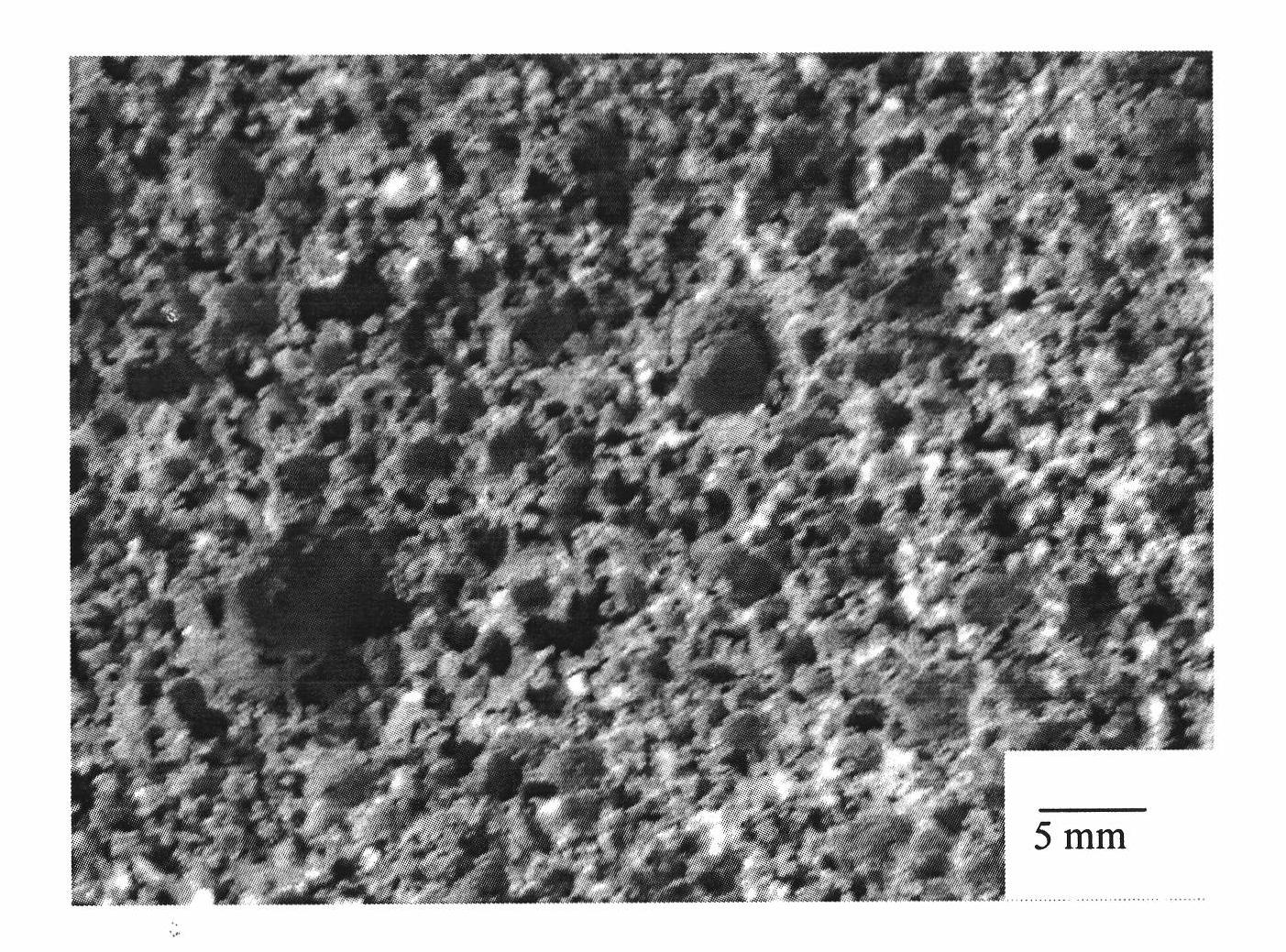

Image

Examples

Embodiment 1

[0040] The first step, cold pressing + hot pressing to prepare magnesium alloy foam prefabricated block

[0041] First, 200 mesh pure magnesium powder and 400 mesh pure aluminum powder are mixed in a mass ratio of 4:1 to form a metal powder mixture, and then 325 mesh TiH that accounts for 1.0% of the metal powder mixture mass percentage 2 The powder foaming agent is added to the metal powder mixture, and the three are fully mixed by a ball mill, and the uniformly mixed composite powder is put into a mold, and then cold-pressed with a hydraulic press at a pressure of 250 MPa at room temperature to keep The pressing time is 30s, and the cold-pressed prefabricated block is taken out, and then the cold-pressed prefabricated block is hot-pressed under the conditions of a hot-pressing temperature of 380°C, a pressure of 180MPa, and a holding time of 30s. , making a magnesium alloy foam prefabricated block;

[0042] The second step is to prepare foamed magnesium alloy

[0043] Put ...

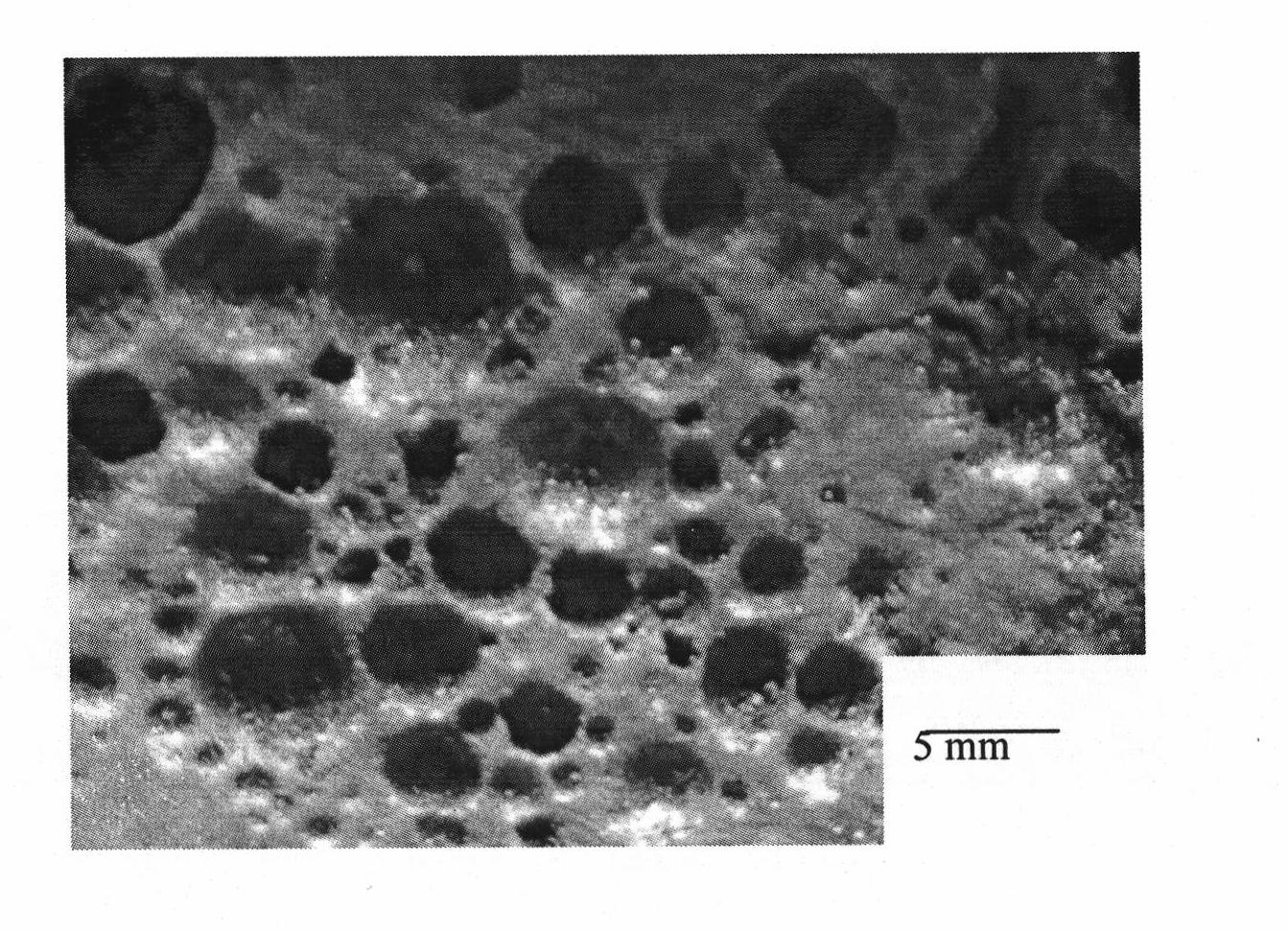

Embodiment 2

[0046] The first step, cold pressing + hot pressing to prepare magnesium alloy foam prefabricated block

[0047] First, 150 mesh pure magnesium powder and 325 mesh pure aluminum powder are mixed in a mass ratio of 4:1 to form a metal powder mixture, and then 200 mesh TiH which accounts for 2.5% of the metal powder mixture mass percentage 2 The powdered foaming agent is added to the metal powder mixture, and the three are fully mixed by a ball mill, and the uniformly mixed composite powder is put into a mold, and then cold-pressed with a hydraulic press at a pressure of 350 MPa at room temperature to keep The pressing time is 30s, and the cold-pressed prefabricated block is taken out, and then the cold-pressed prefabricated block is hot-pressed under the conditions of hot-pressing temperature of 380°C, pressure of 180MPa, and holding time of 40s. , making a magnesium alloy foam prefabricated block;

[0048] The second step is to prepare foamed magnesium alloy

[0049] Put the...

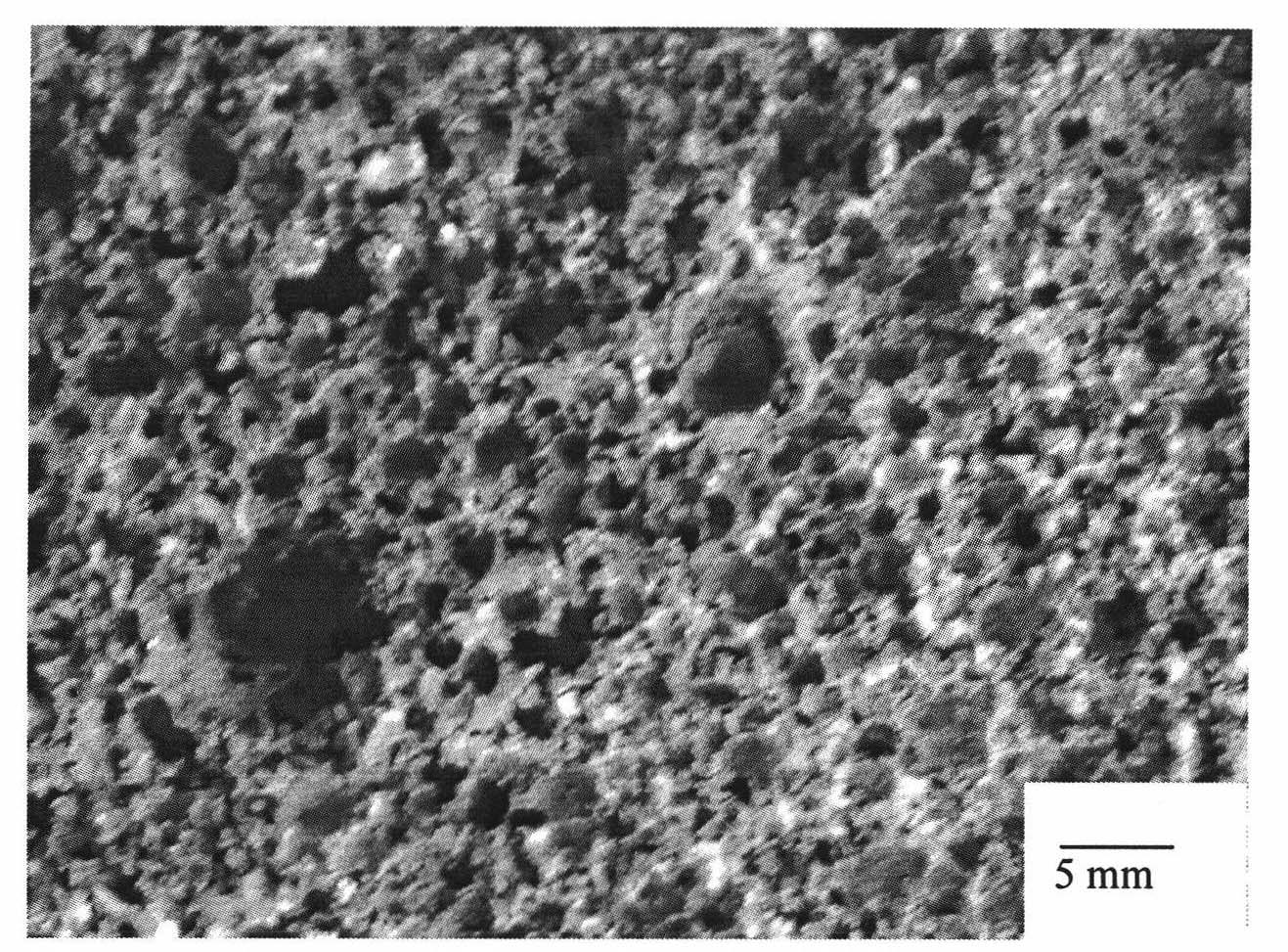

Embodiment 3

[0051] The first step, cold pressing + hot pressing to prepare magnesium alloy foam prefabricated block

[0052] First, 250 mesh pure magnesium powder and 400 mesh pure aluminum powder are mixed in a mass ratio of 9:1 to form a metal powder mixture, and then 270 mesh TiH that accounts for 1.5% of the metal powder mixture mass percentage 2 The powdered foaming agent is added to the metal powder mixture, and the three are fully mixed by a ball mill, and the uniformly mixed composite powder is put into a mold, and then cold-pressed with a hydraulic press at a pressure of 350 MPa at room temperature to keep The pressing time is 60s, and the cold-pressed prefabricated block is taken out, and then the cold-pressed prefabricated block is hot-pressed under the conditions of hot-pressing temperature of 350°C, pressure of 150MPa, and holding time of 40s. , making a magnesium alloy foam prefabricated block;

[0053] The second step is to prepare foamed magnesium alloy

[0054] The magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com