Technological process and apparatus for advanced oxidation degradation of nitrobenzene wastewater

A technology of advanced oxidation and process method, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of slow degradation rate of nitrobenzene, meet the treatment requirements, and high cost, and reduce water treatment Cost reduction, reduction in handling costs, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

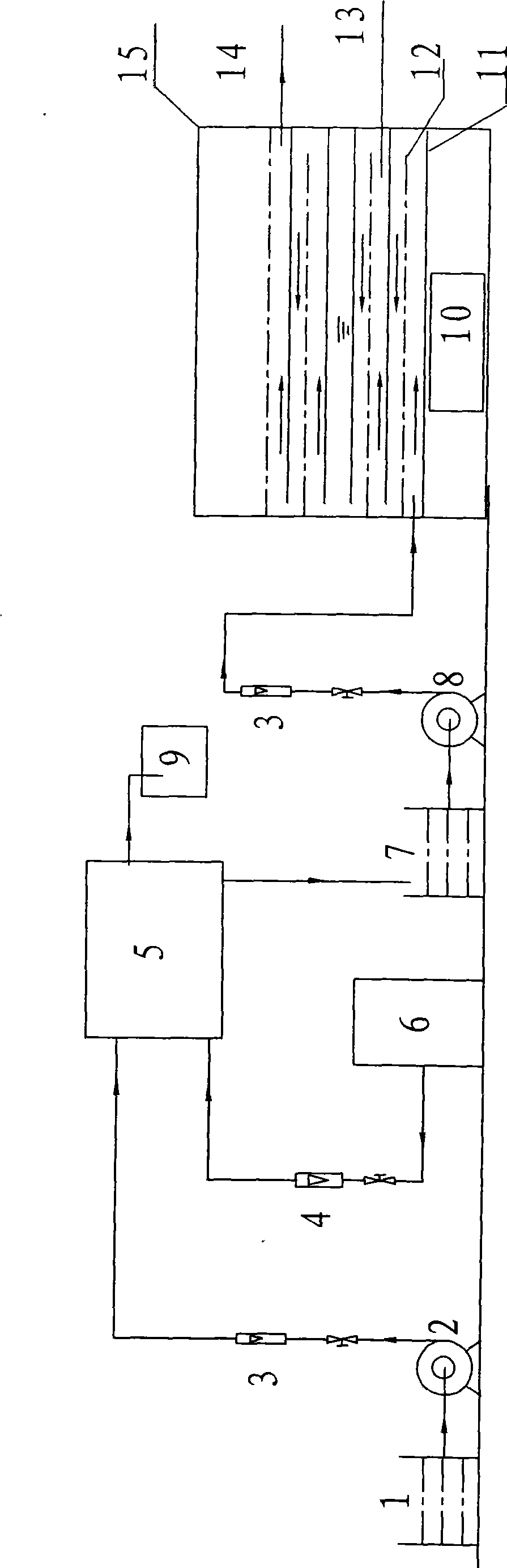

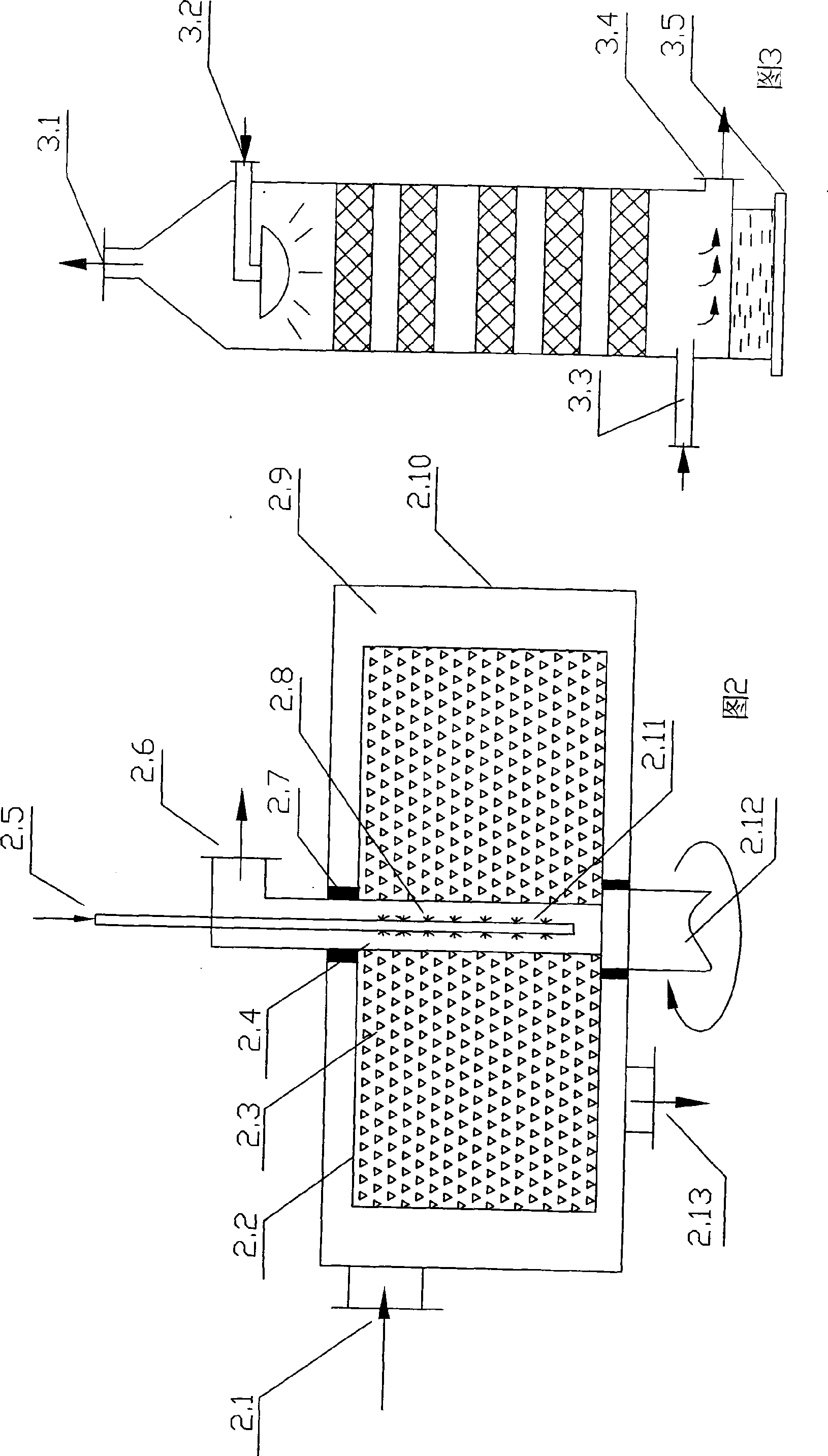

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Treatment of dinitrotoluene (DNT) in wastewater from explosives and propellant plants. The initial concentration of dinitrotoluene in the wastewater is 195mg / L. Using ozone oxidation method to treat 10L / h wastewater, the volume ratio of wastewater to ozone is 500L / m 3 , The ozone concentration is 13.5mg / L, after 180min of degradation, the removal rate of dinitrotoluene is only 10%; the ultrasonic / ozone method is used for treatment, the treatment volume is unchanged, the ozone concentration is unchanged, and the ultrasonic sound intensity is 1W / cm 2, Frequency is 28kHz, pH=11, after 180min, the removal rate of dinitrotoluene is 30%; ozone and DNT wastewater undergo gas-liquid mass transfer reaction in a rotating packed bed to complete the preliminary degradation of wastewater, and then the wastewater enters Ultrasonic-electrolyzed wastewater is treated in a reaction tank. Ultrasonic sound intensity, frequency and concentration of ozone remain unchanged, use ammoni...

Embodiment 2

[0039] Example 2: Treatment of chloronitrobenzene wastewater. Nitro-containing benzene organics in wastewater mainly include nitrophenol, nitrobenzene, and chloronitrophenol, with a total concentration of 21mg / L, and wastewater COD of 1103mg / L. Using ozone / electrolysis method to treat 80L / h wastewater, the ozone concentration is 10mg / L, and the surface is coated with Ti RuO 2 It is anode, stainless steel is cathode, current density is 40mA / cm 2 After 180 minutes of degradation, the total removal rate of nitrophenol, nitrobenzene, and chloronitrophenol is 70%, and the removal rate of COD is 20%; ozone and chloronitrobenzene wastewater undergo gas-liquid mass transfer in a rotating packed bed Reaction, the liquid-gas volume ratio of wastewater to ozone is 50L / m 3 , The ozone concentration is 10mg / L, the preliminary degradation of wastewater is completed, and then the wastewater enters the wastewater reaction tank equipped with ultrasonic- / electrolysis for treatment. Ultrasonic sound...

Embodiment 3

[0040] Example 3: Treatment of nitrophenol wastewater. Equipped with 100mg / L nitrophenol solution, the processing capacity is 5L / h, ozone and nitrophenol wastewater undergo gas-liquid mass transfer reaction in the packed tower, and the liquid-to-gas volume ratio of wastewater to ozone is 100L / m 3 , The ozone concentration is 18mg / L, complete the preliminary degradation of wastewater, and then the wastewater enters the wastewater reaction tank equipped with ultrasonic-electrolysis for treatment. Ultrasonic sound intensity is 50W / cm 2 , The frequency is 40kHz, the pH is adjusted by NaOH=10, and the current density is 10mA / cm 2 , The lead dioxide electrode is the anode, and the stainless steel is the cathode. After 60 minutes of treatment, the removal rate of nitrophenol reaches 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com