Titanium dioxide nanoplate and synthesizing method thereof

A technology of titanium dioxide and synthesis method, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effects of low price, easy availability of raw materials, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Measure 5ml of tetrabutyl titanate and 0.4ml of hydrofluoric acid into the reaction axe, react at 180°C for 24 hours, take out the sample and wash it twice with distilled water and ethanol, then wash it with NaOH solution for 10 times, and finally wash it with water for 3 times time, and then dry.

[0031] 2) Preparation of nano-titanium dioxide solution: Weigh 60 mg of titanium dioxide nanosheets prepared by the above method, prepare a 0.06 g / L solution with distilled water, and measure 3 mL of the solution into a photocatalytic reactor.

[0032] 3) Put the photocatalytic reactor equipped with the nano-titanium dioxide solution under an ultraviolet lamp, and add 50 μL, 1 mmol / L methyl orange solution to conduct a photocatalytic test.

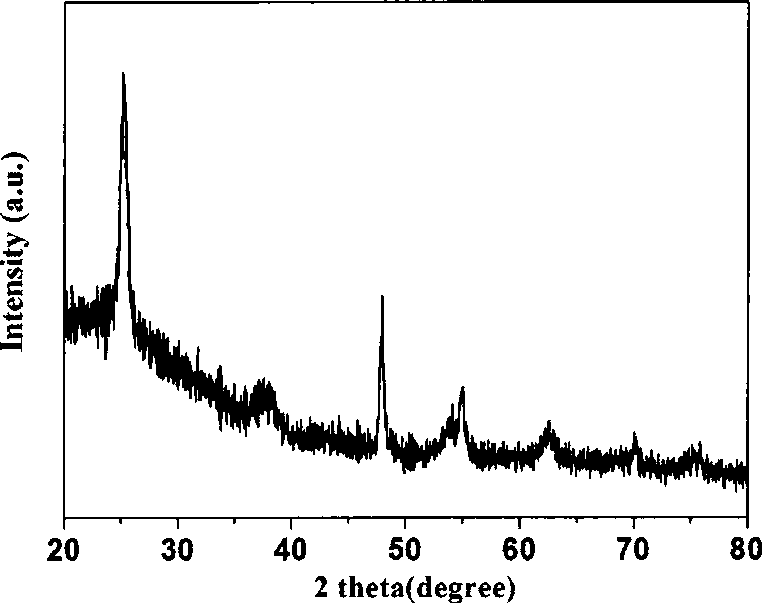

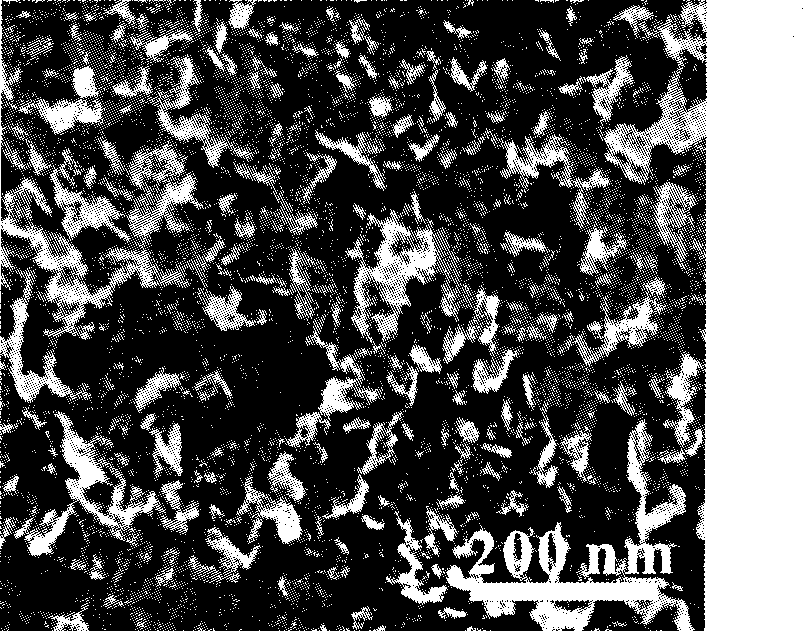

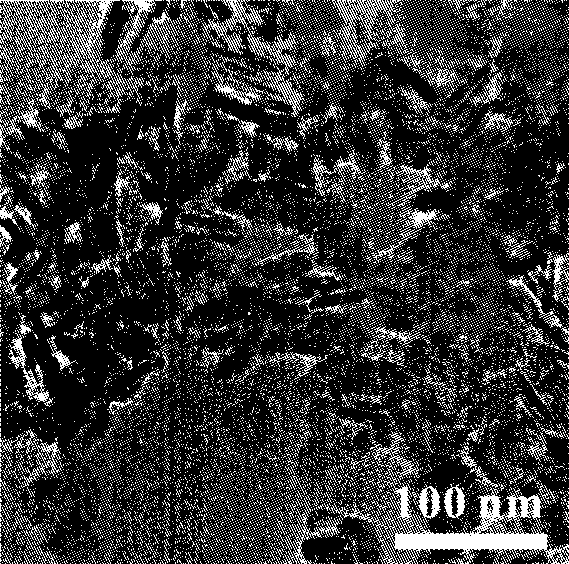

[0033] The product is characterized by XRD, SEM, TEM as TiO2 flake structure. figure 1 5ml tetrabutyl titanate and 0.4ml hydrofluoric acid were put into the reaction axe and reacted at 180°C for 24h to obtain the X-ray powder diffrac...

Embodiment 2

[0035] Similar to Example 1, the difference is that the volume ratio of tetrabutyl titanate to hydrofluoric acid is 20:1, the reaction temperature is 230° C., and the reaction time is 10 h.

Embodiment 3

[0037] 1) Measure 5ml of tetrabutyl titanate and 0.8ml of hydrofluoric acid into the reaction kettle, react at 180°C for 24 hours, take out the sample and wash it with distilled water and ethanol for 3 times, then wash it with NaOH solution for 8 times, and finally wash it with water for 4 hours time, and then dry.

[0038] 2) Preparation of nano-titanium dioxide solution: Weigh 60 mg of titanium dioxide nanosheets prepared by the above method, prepare a 0.06 g / L solution with distilled water, and measure 3 mL of the solution into a photocatalytic reactor.

[0039] 3) Put the photocatalytic reactor equipped with the nano-titanium dioxide solution under an ultraviolet lamp, and add 50 μL, 1 mmol / L methyl orange solution to conduct a photocatalytic test. It takes about 3100s to prepare the sample in Example 2.

[0040] The product was characterized as TiO by XRD, SEM, TEM 2 flaky structure. Figure 5 Give 5ml tetrabutyl titanate and 0.4ml hydrofluoric acid into the reaction a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com