Method for grinding conical bearing large cone angle roller for wind power generation

A technology of tapered bearings and tapered rollers is applied in the field of roller grinding with large taper angle of wind power generation tapered bearings, and achieves the effect of improving the variation of the roller diameter and solving the technical difficulties of grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

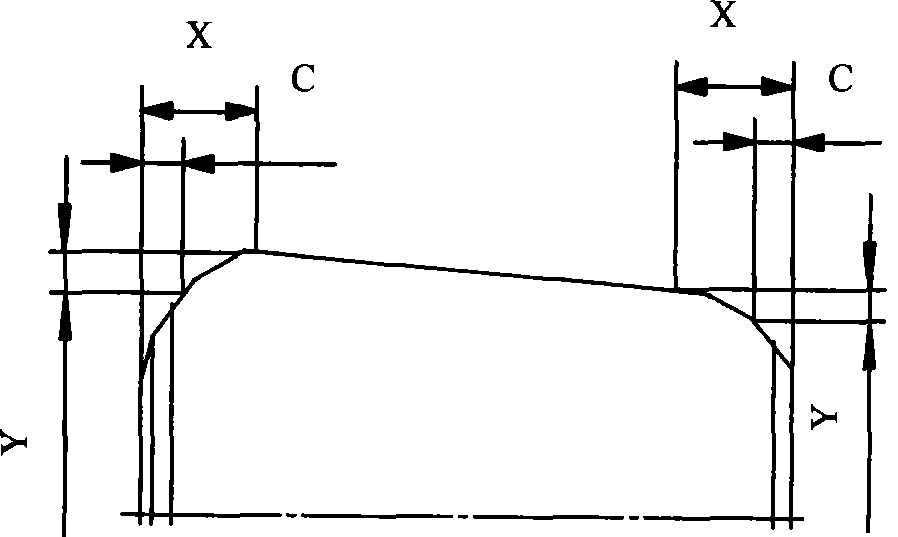

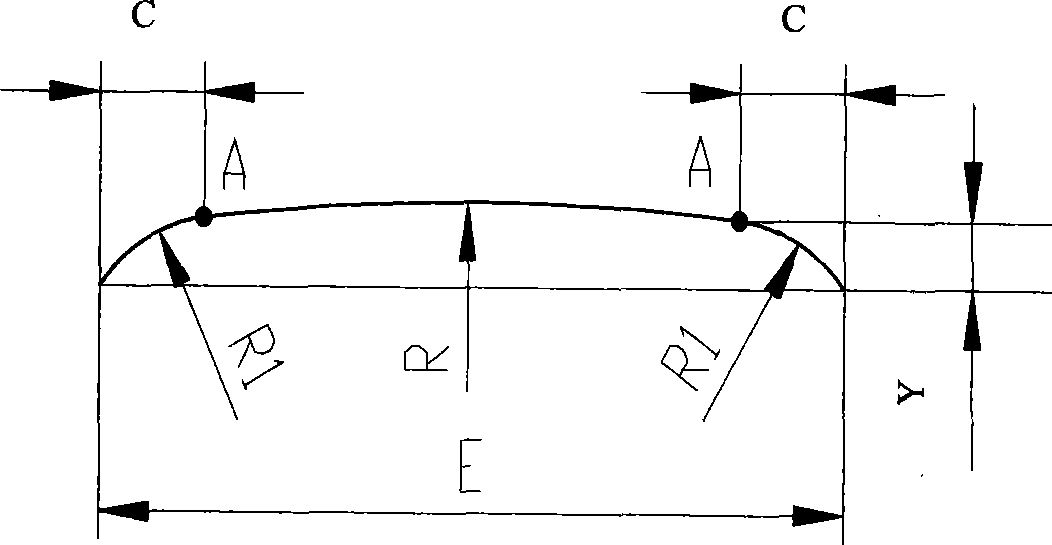

[0012] as attached figure 1 , figure 2 As shown, the roller processing is about 400 grains. Describe the processing technology of the final grinding outer diameter and grinding slope of tapered rollers. The diameter tolerance of the final grinding product of the roller requires ±0.02mm, and the depth of the grinding slope of the roller requires 13μm~21μm. The final grinding process is divided into three parts according to the difference in the outer diameter of the roller, that is, the outer diameter of the roller is divided into +0.06mm, 0.035mm, and 0.015mm. That is to say, the final grinding process uses rubber 80# grinding wheel for grinding. After a period of time, the self-sharpness of the grinding wheel particles is poor. In order to ensure that the surface roughness of the roller reaches Ra0.08μm, the surface of the grinding wheel must be repaired frequently. At this time, first use a roller with an outer diameter of +0.06mm to grind to +0.035mm, so that the self-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com