Residue heat temperature difference electricity conversion power generation system for internal combustion engine

A power generation system, thermoelectric power generation technology, applied in the direction of machine/engine, generator/motor, electrical components, etc., can solve the problem that it is difficult to make breakthrough progress, and achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

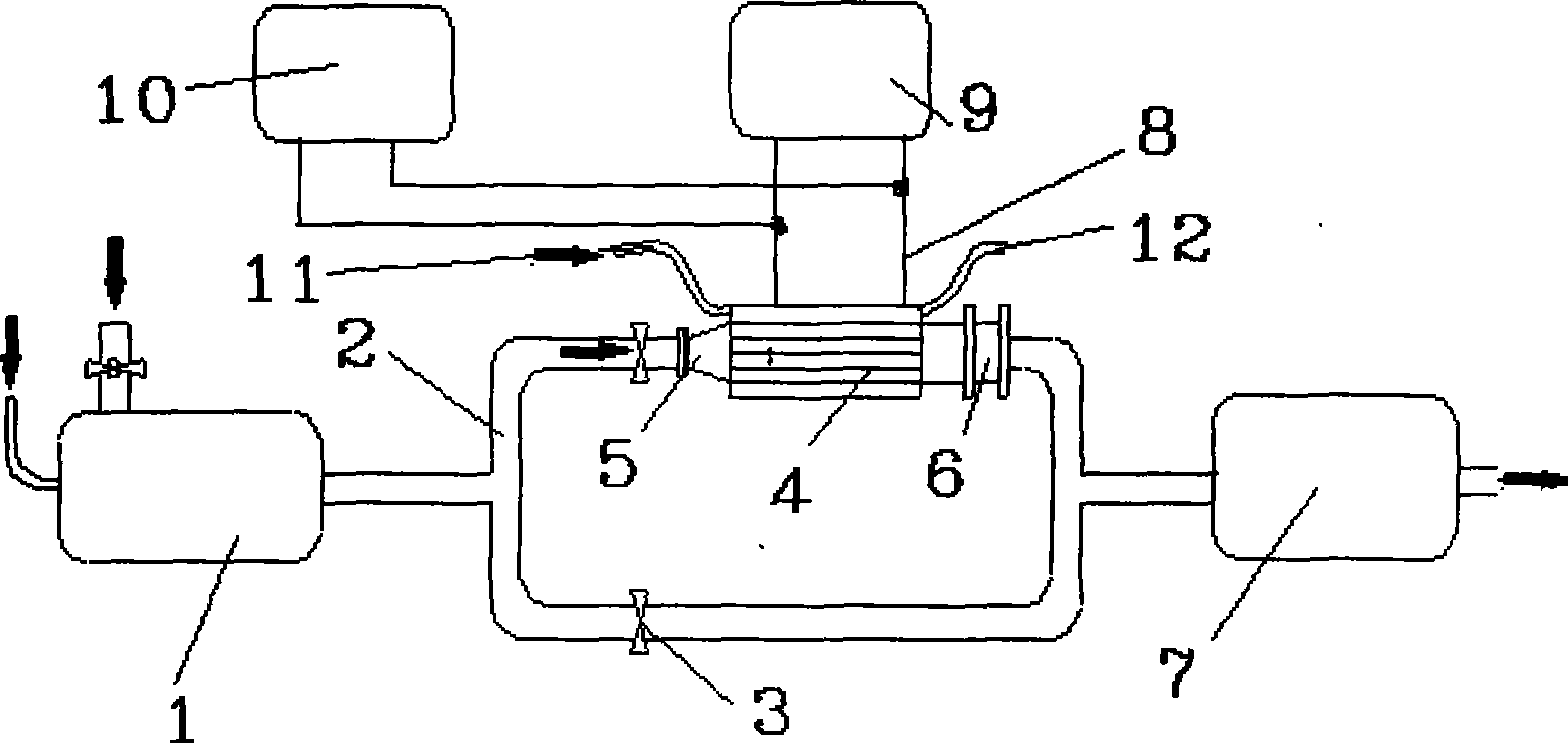

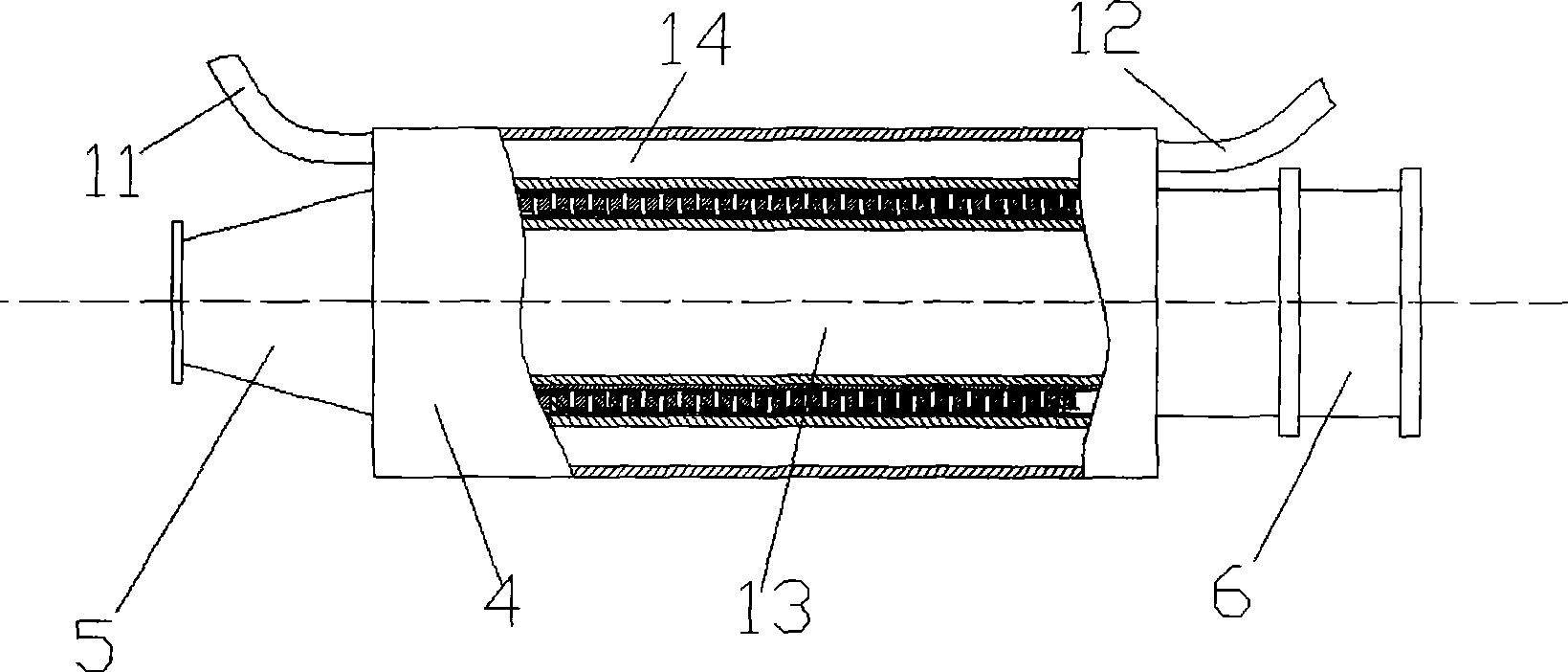

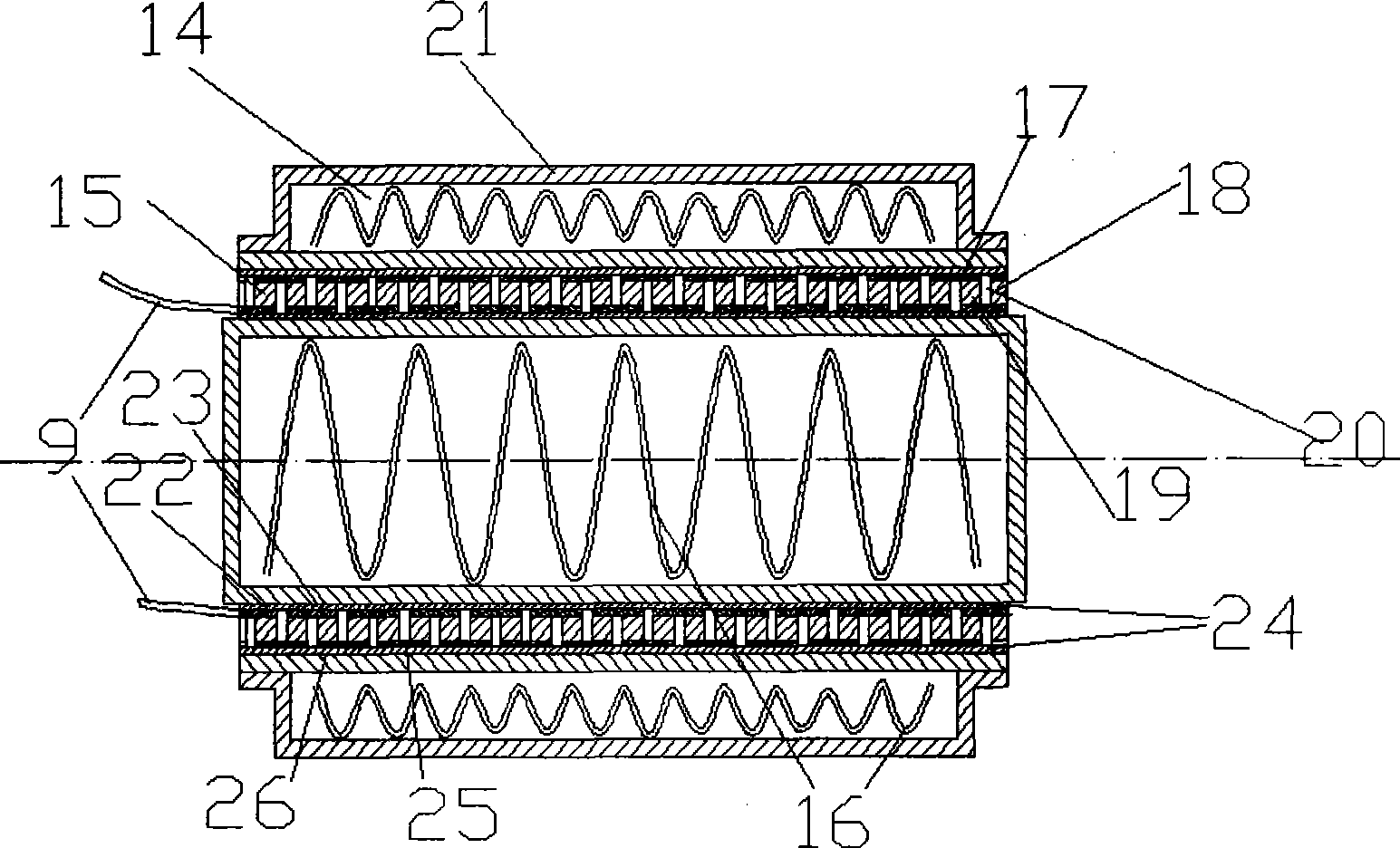

[0010] As shown in the drawings, the present invention consists of engine 1, exhaust main pipe 2, bypass branch pipe 3, thermoelectric power generation device 4, flue gas heat exchanger inlet 5, flue gas heat exchanger outlet 6, muffler 7, electrode connection 8. Electrical equipment 9, storage battery 10, circulating water heat exchanger inlet 11 and circulating water heat exchanger outlet 12. The thermoelectric generator 4 is placed between the exhaust port of the diesel locomotive and the muffler 7, and is composed of the engine 1 The exhaust pipe is divided into an exhaust main pipe 2 and a bypass branch pipe 3. The exhaust main pipe 2 is connected to the thermoelectric power generation device 4, the flue gas heat exchanger 13 and the flue gas heat exchanger inlet 5, and the flue gas heat exchanger outlet 6 is connected to After the bypass branch pipe 3 merges, it is connected to the muffler 7, the electrode wire 8 of the thermoelectric power generation device 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com