Large-diameter hot water pipe non-compensation direct-burried laying method

A hot water pipeline and pipeline laying technology, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. The problem of short service life of the compensator can achieve the effect of small daily maintenance workload, improved heating reliability, and low operation and management costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

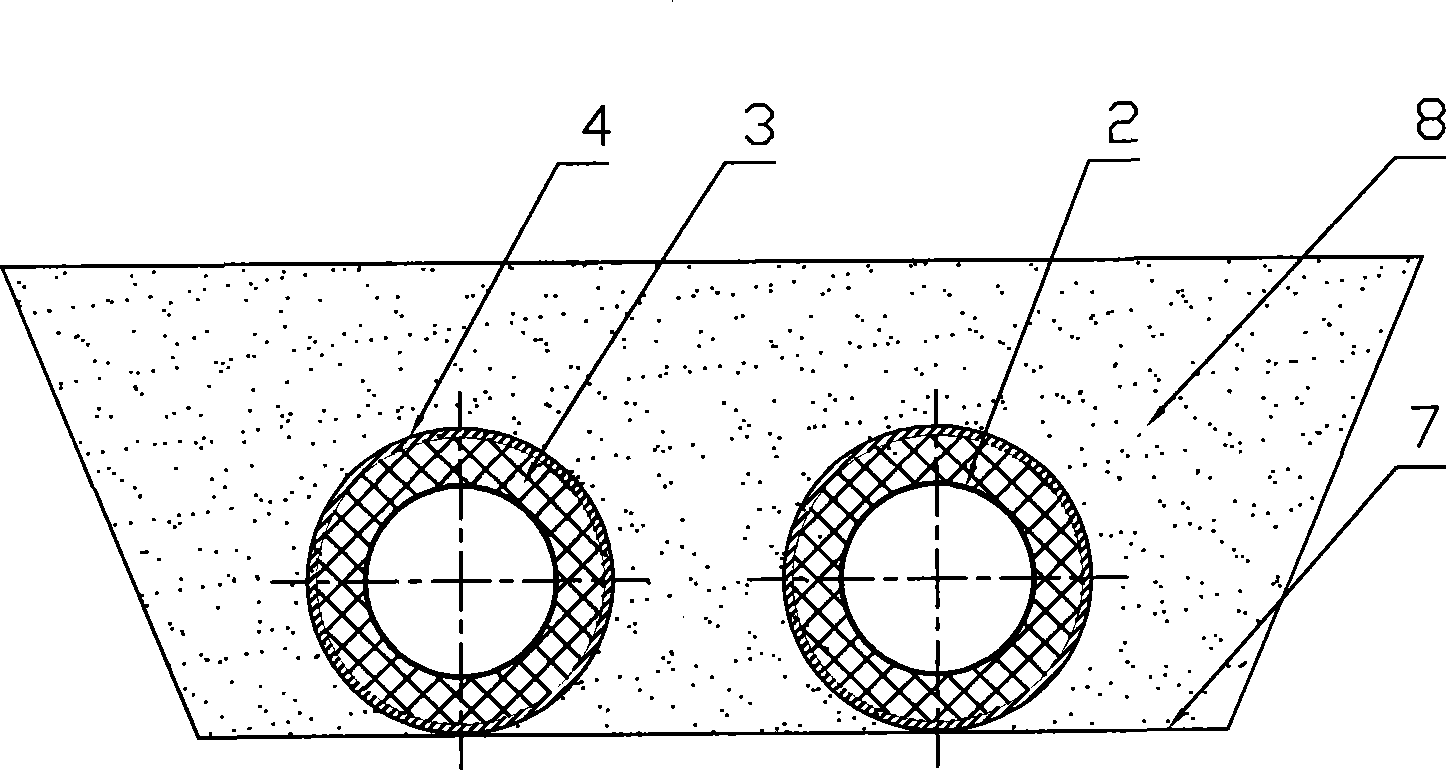

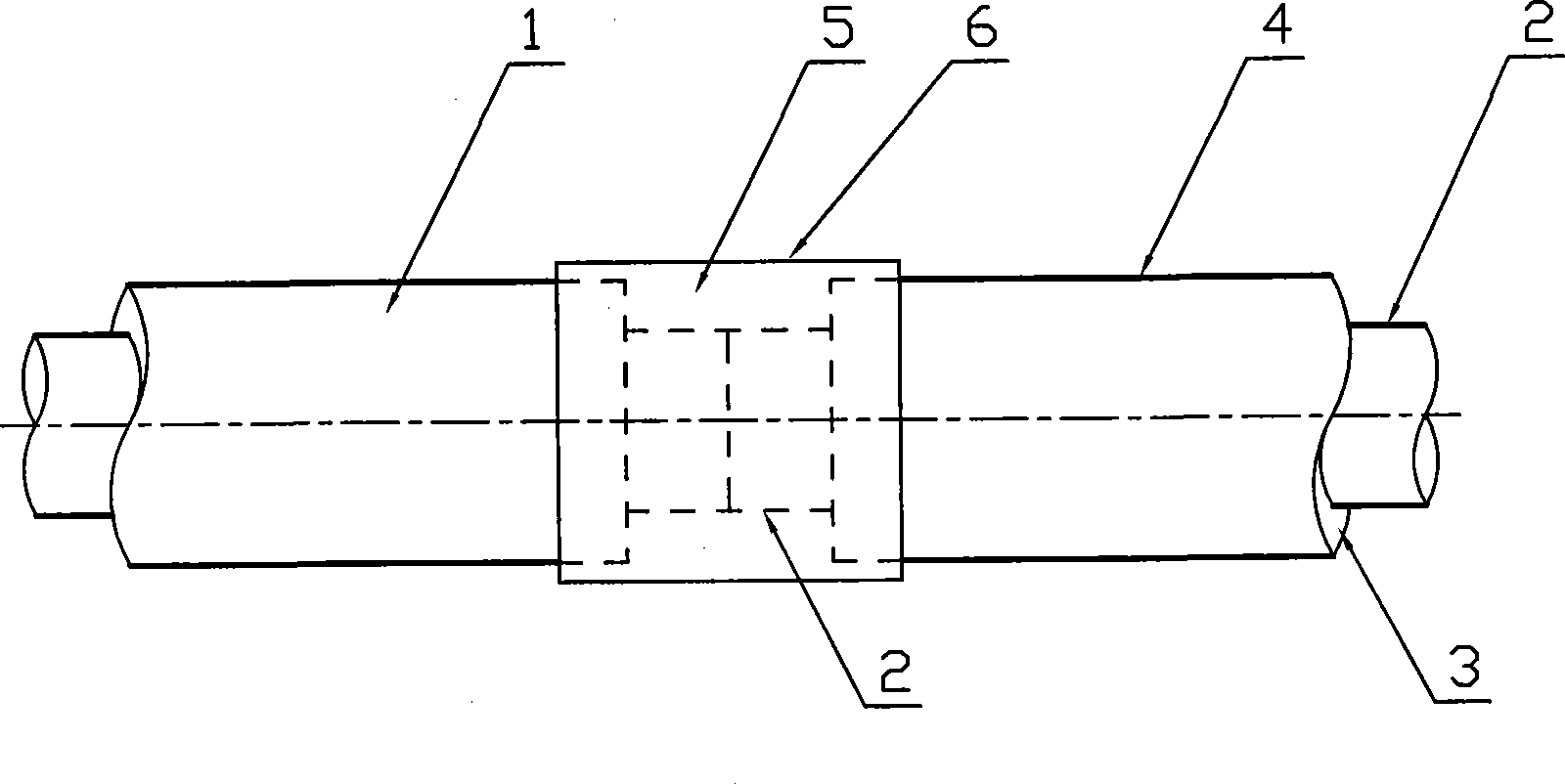

[0030] like figure 1 , 2 As shown in the present invention, a large-diameter hot water pipeline non-compensated direct burial laying method, the main trunk line diameter adopted is DN1000, and the laying method includes the following steps:

[0031] (1) Set the temperature of the heating medium to 130°C and the pressure inside the pipeline to 2.2MPa;

[0032] (2) Determine the laying depth of the direct-buried pipeline according to the condition of the underground intersecting pipelines along the line. The excavation depth of the trench 7 is about 3.5-4.5m;

[0033] (3) The bottom of the trench 7 is rammed and leveled. If the soil is inconsistent in hardness and softness, it needs to be dealt with so that the bottom bearing capacity will not differ too much;

[0034] (4) Prefabricated direct-buried thermal insulation pipe 1 is processed in the factory, and prefabricated direct-buried thermal insulation pipe 1 is made up of steel pipe 2, thermal insulation layer 3, outer shea...

Embodiment 2

[0044]The diameter of the trunk line used is DN800, and the laying method is the same as the steps in Example 1, wherein the heating medium is set at 70°C, and the internal pressure of the pipeline is 0.8MPa; the prefabricated direct-buried insulation pipe 1 and the steel pipe 2 are processed in the factory It is made of low-carbon steel materials, including straight pipe fittings, elbow pipe fittings and elbow pipe fittings. The length of straight pipe fittings is generally 6 to 12 meters. The bend pipe fittings and elbow pipe fittings are prefabricated according to the design size; The layer 3 and the outer protective layer 4 are prefabricated into an integral structure, and the insulation layer 3 is made of rigid polyurethane foam with a compressive strength not less than 0.3MP.

[0045] The present invention is a non-compensated direct-buried laying method for large-diameter hot water pipelines. It is not necessary to install compensators on the pipelines within a fixed dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com