Steel for boron micro-alloying waste heat treatment steel bar

A boron microalloying and residual heat treatment technology, applied in the field of hot-rolled ribbed steel for reinforced concrete, can solve the problems of high cooling strength, limited rolling speed, low yield, etc., saving alloy resources and reducing production Cost, effect of reducing alloy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

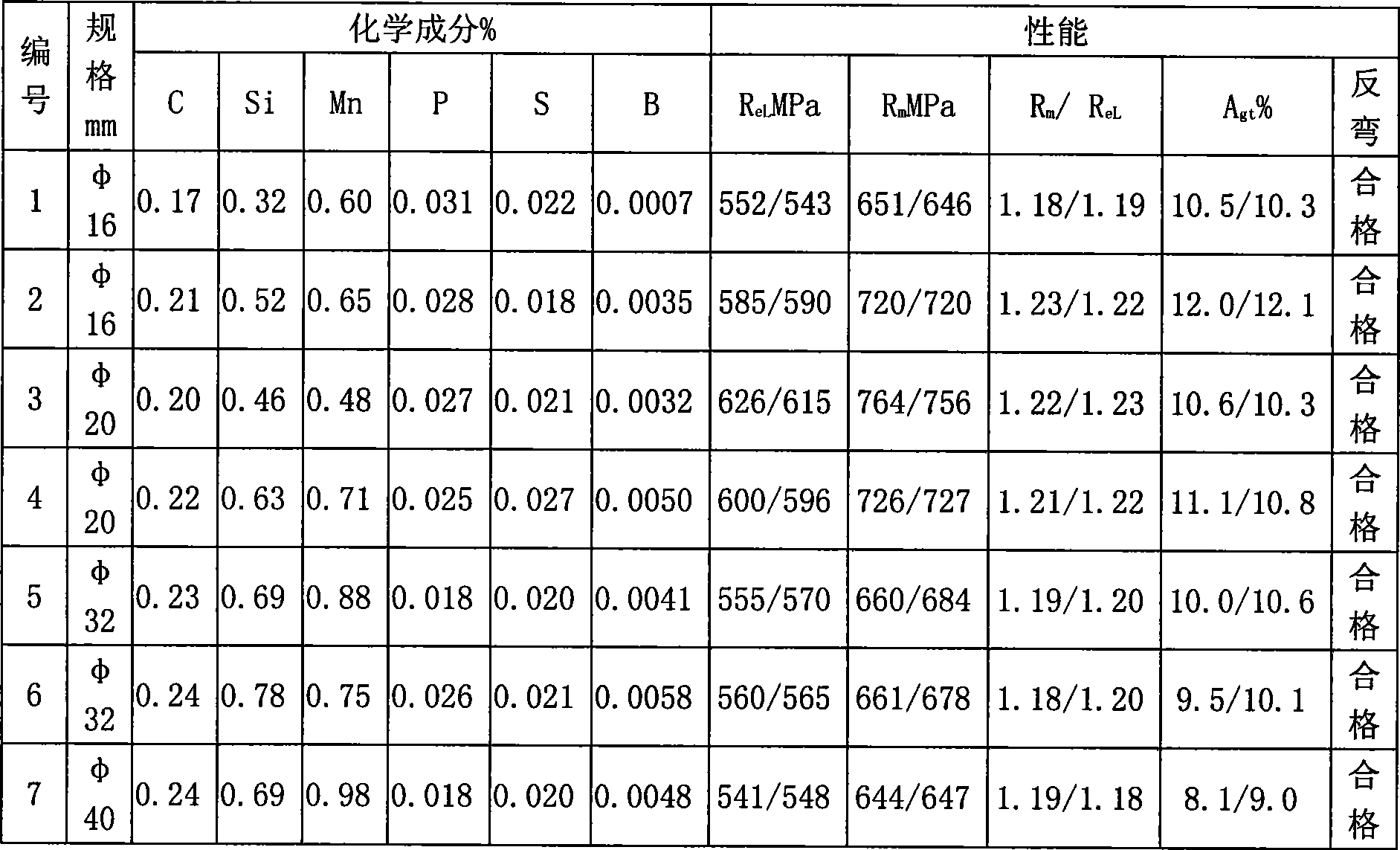

[0013] The composition and properties of the steel bars produced by the present invention are shown in Table 1. The production conditions are converter smelting, continuous casting into 150mm square billets, rolling on continuous bar mills, and waste heat treatment after rolling.

[0014] Table 1 Composition embodiment and performance of the present invention

[0015]

[0016] Note: The sample of the reverse bending test should be bent around the center of the bend, the bending angle is 90°, the diameter of the center of the bend is not more than 7d (d is the nominal diameter), the sample is artificially aged (the sample is heated to 100°C and kept for 60min), and then Backbend at least 20°.

[0017] It can be seen that the boron microalloyed waste heat treated steel bars have high strength and toughness, R eL ≥540MPa, strong yield ratio R m / R eL ≥1.15, A gt ≥7.5%, the anti-bending performance is good, and the manganese content is less than 1.0%, which saves alloy reso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com