Equipment for producing oxidized pellet and method for producing oxidized pellet by using the same

A technology for oxidizing pellets and equipment, which is applied in the field of equipment for producing oxidizing pellets for blast furnace ironmaking, can solve the problems of high addition of bentonite and excessive decrease in the iron content of the pellets, and achieves the effect of improving the iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

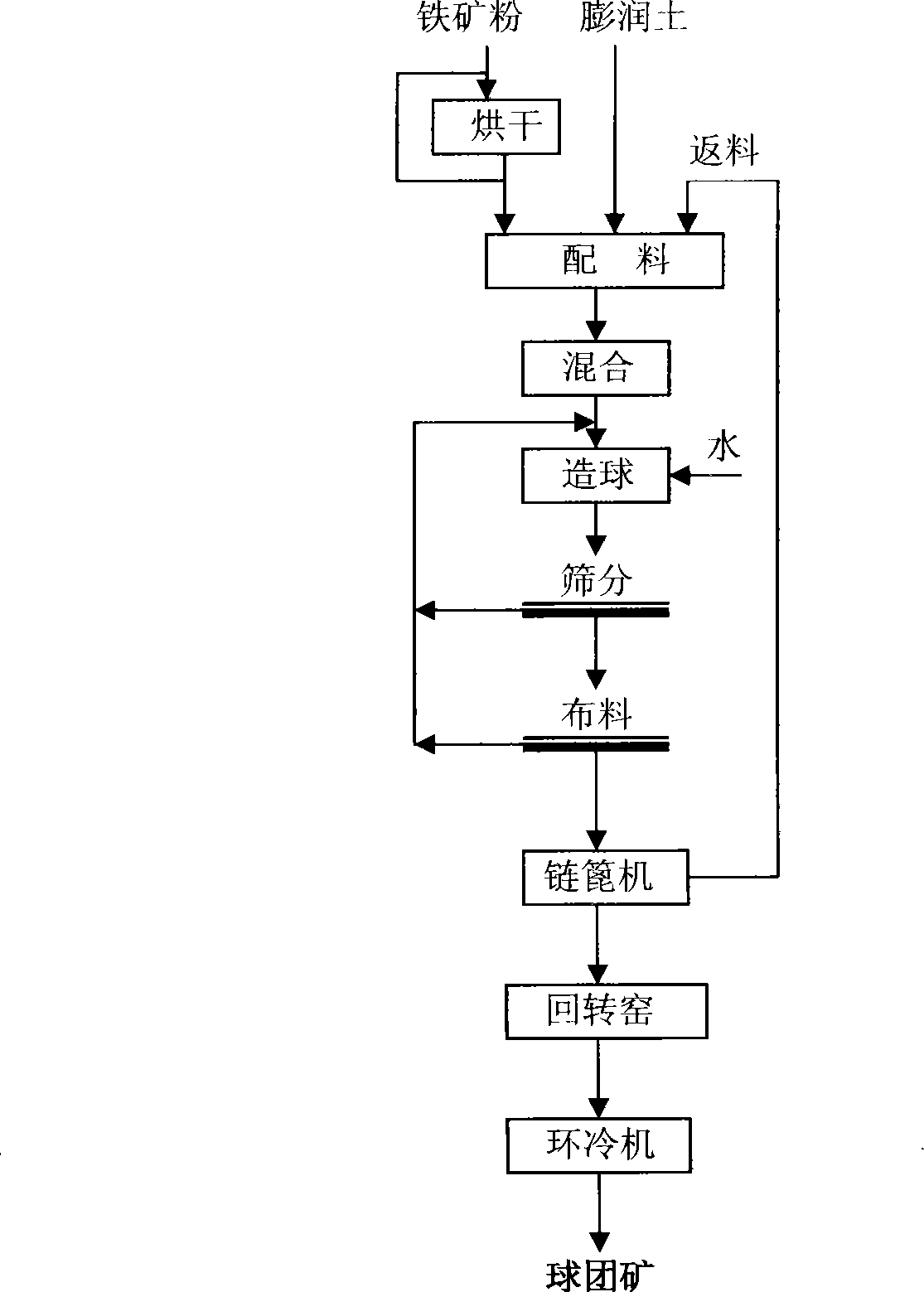

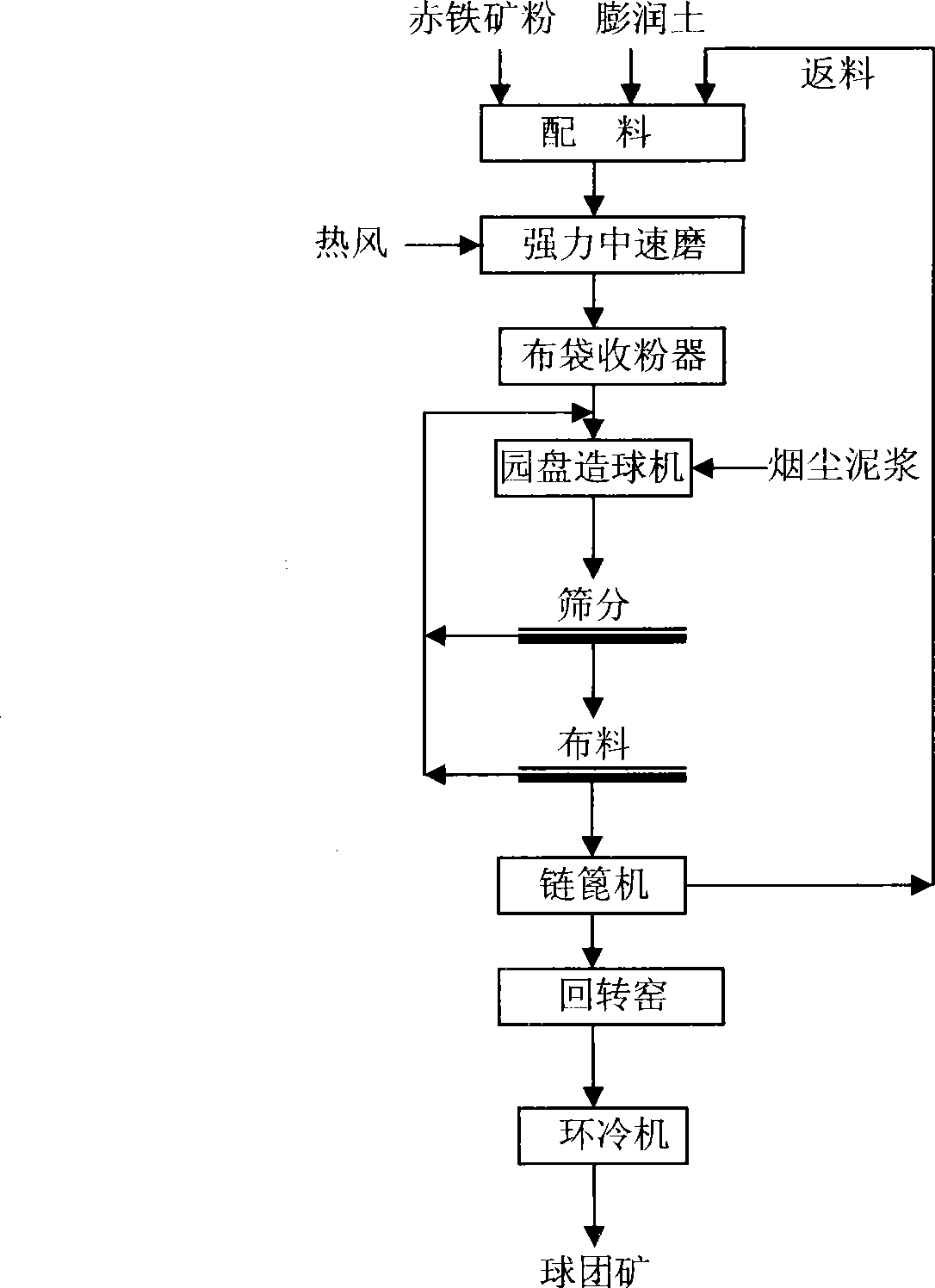

[0034] figure 2 The structural diagram of the equipment for producing oxidized pellets for the present invention, such as figure 2 As shown, the present invention changes the traditional grate-rotary kiln production equipment for the production of oxidized pellets in the rotary kiln, uses hematite powder for iron and steel production oxidized pellets, and provides a medium-speed grinding-grit- The new production equipment for the production of oxidized pellets by the rotary kiln is added between the ingredients and the pelletizing device of the traditional grate-rotary kiln production device for the production of oxidized pellets by the rotary kiln for crushing, drying, Grinding device for wind selection (powerful medium-speed grinding) and material collection device after grinding (bag powder collector). The ore powder collected by the bag powder collector enters the disc pelletizer through the feeding device, and sprays the converter dust mud into the disc pelletizer thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com