Molecular sieve absorbent

A technology of adsorbent and molecular sieve, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of regeneration difficulties, reduce the adsorption capacity of carbon-based adsorbents, reduce the desulfurization effect of adsorbents, etc., and achieve good regeneration and long service life Prolonged, high adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

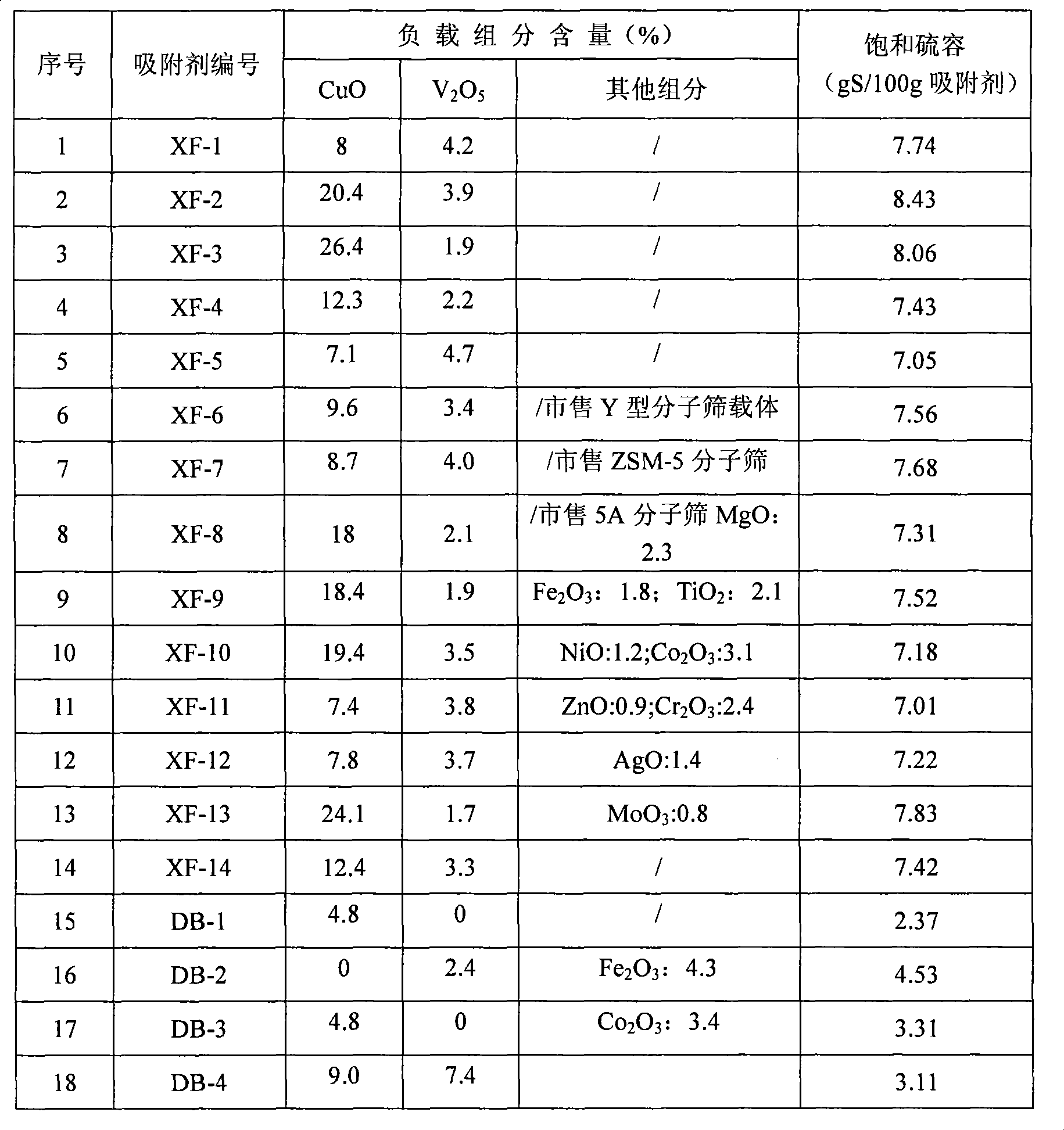

Examples

Embodiment 1

[0053] Slowly add 20g of water glass (SiO 2 25.5%, Na 2 O9.3%, H 2 (065.2%), warming up to 70°C, adjusting pH=8.5, adding directing agent (12Na 2 O:Al 2 o 3 : 5SiO 2 : 28OH 2 (0), after stirring for 30min, filter and wash, then add 10g concentration and be the ammonia solution of 5% vanadium pentoxide, add 2ml polyacrylic acid to extrude and granulate, dry, and roast at 400 DEG C for 4 hours to obtain vanadium-containing Molecular sieve, its SiO 2 / Al 2 o 3 is 3.4.

Embodiment 2

[0055] Slowly add 160g of 20% Na 2 SiO 3 9H 2 O solution, warm up to 90°C, adjust pH=9.5, add directing agent (8Na 2 O:Al 2 o 3 : 8SiO 2 : 300H 2 O), after stirring for 60min, filter and wash, add 10g5%NH 4 VO 3 ammonia solution, add 2ml of polyvinyl alcohol to extrude and granulate, after drying, bake at 600°C for 2 hours to obtain a molecular sieve containing vanadium, its SiO 2 / Al 2 o 3 is 6.8.

Embodiment 3

[0057] Take by weighing the molecular sieve that 5g embodiment 1 makes, after vacuumizing, add 100ml concentration and be 10% Cu(SO 4 ) 2 The solution was placed on an ultrasonic oscillator, soaked for 600min at an ultrasonic frequency of 30kHz and a temperature of 50°C, filtered, dried at 120°C, and then baked in a muffle furnace at 450°C for 12 hours to obtain the adsorbent XF-1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com