Optical layer pieces and manufacture method thereof

A laminated sheet and optical technology, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as uneven white turbidity, uneven turbidity, and increased turbidity, and achieve the purpose of inhibiting the occurrence of whitening spots and coating Good surface condition and the effect of suppressing the increase of turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

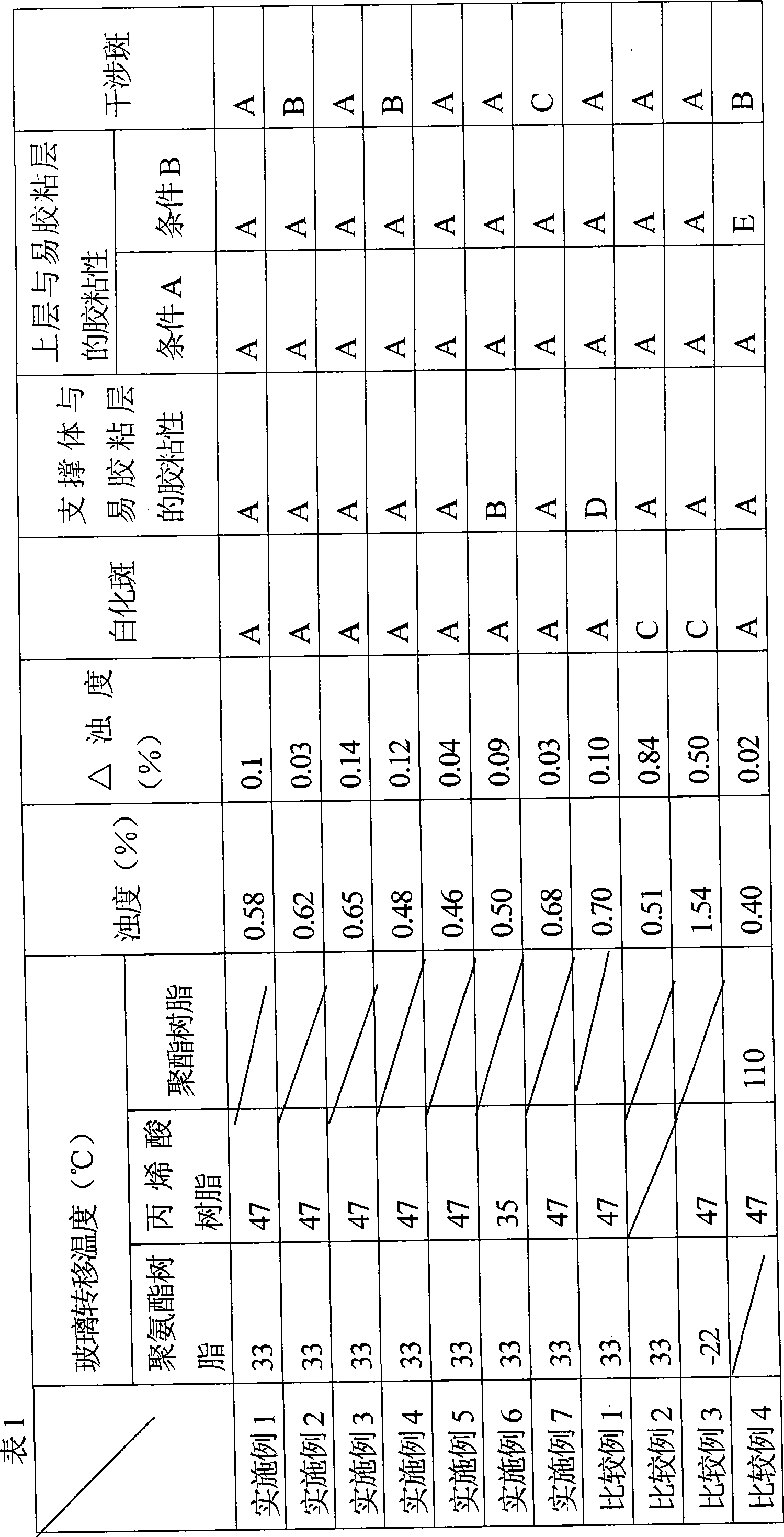

[0050] Hereinafter, the laminated sheet of the present invention and its production method will be described with reference to Examples 1 to 7 and Comparative Examples 1 to 4. In addition, in the following Examples etc., when the manufacturing method of the laminated sheet 10 etc. are the same, it demonstrates in detail only in Example 1, and omits description in others.

[0051] The support body of the laminated sheet was formed in the following order. First, dry polyethylene terephthalate (hereinafter referred to as PET) resin with an intrinsic viscosity of 0.66 formed by polycondensation using Ge as a catalyst until the water content is below 50ppm, and the temperature of the heater is set at 280-300 ℃ in the extruder to melt it. The melted PET resin is sprayed from the mold part onto the chill roll to which static electricity is applied to obtain an amorphous matrix. The obtained amorphous matrix was stretched 3.3 times along the traveling direction of the matrix, and th...

Embodiment 2

[0111] A laminated sheet was produced in the same manner as in Example 1 except that the adhesive ratio of the coating liquid formulation for an easily adhesive layer was changed. Specifically, the ratio of the resin adhesive in the formulation of the coating solution for an easily-adhesive layer was changed as follows, and all other additives were the same as in Example 1.

[0112] 23.9 parts by mass of polyurethane resin adhesive

[0113] (Manufactured by Mitsui Chemicals Co., Ltd., Oresta-UD350, solid content 38%, glass transition temperature 33°C)

[0114] 12.6 parts by mass of acrylic resin adhesive

[0115] (AS563 manufactured by Daicel Chemical Co., Ltd., solid content 27.5%, glass transition temperature 47°C)

Embodiment 3

[0117] Except for changing the coating solution formulation for the easy-adhesive layer, everything is the same as in Example 1, and a laminated sheet is produced.

[0118]15.4 parts by mass of polyurethane resin adhesive

[0119] (Manufactured by Mitsui Chemicals Co., Ltd., Oresta-UD350, solid content 38%, glass transition temperature 33°C)

[0120] Acrylic resin adhesive 2.1 parts by mass

[0121] (AS563 manufactured by Daicel Chemical Co., Ltd., solid content 27.5%, glass transition temperature 47°C)

[0122] 2.9 parts by mass of crosslinking agent

[0123] (manufactured by Nisshinbo Co., Ltd., CARBODILITEV-02-L2, solid content 40%)

[0124] Additive (filler) 0.95 parts by mass

[0125] (Nippon Aerosil Co., Ltd., AEROSILOX-50, solid content 10%)

[0126] Additive (filler) 0.4 parts by mass

[0127] (manufactured by Nissan Chemical Co., Ltd., Snow-Tex XL, solid content 40%)

[0128] Additive (lubricant) 0.95 parts by mass

[0129] (manufactured by Chukyo Oil & Fat Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com