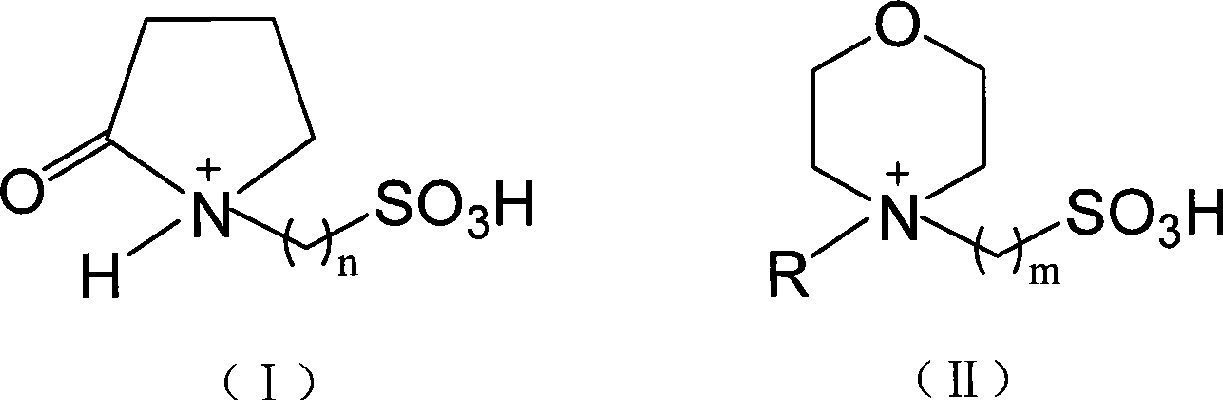

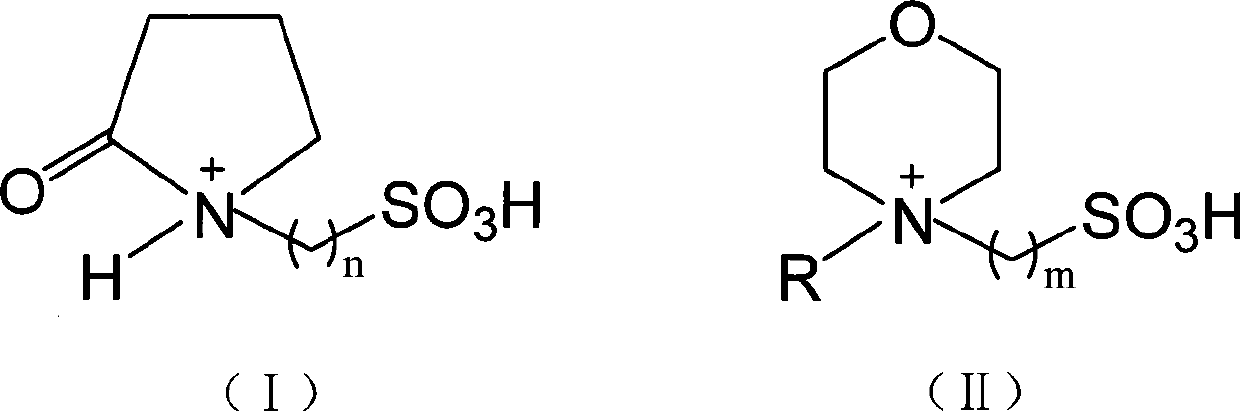

Method for preparing biodiesel by sulfonic acid type ion liquid

An ionic liquid and catalytic preparation technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve the problem of catalyst stability to be improved, and achieve a simplified post-treatment process, a simple separation process, and low corrosiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. Weigh 20g (0.023mol) of soybean oil, 8.83g (0.28mol) of methanol, and 1.6g (0.0053mol) of 1-(3-sulfopropyl)-2-pyrrolidone bisulfate into the autoclave , the reaction temperature is 120° C., the reaction time is 8 hours, after the reaction, the mixture is allowed to stand for stratification, and the biodiesel phase is separated, and distilled at atmospheric pressure to remove a small amount of methanol, and the yield of methyl ester is 96.4%.

Embodiment 2

[0021] Embodiment 2, take by weighing respectively peanut oil 20g (0.023mol), methanol 8.83g (0.28mol), 4-(3-sulfopropyl)morpholine bisulfate 0.8g (0.0026mol) and add in the autoclave, the reaction temperature The temperature was 120°C, and the reaction time was 8 hours. After the reaction, the mixture was allowed to stand for stratification, and the biodiesel phase was separated, and distilled at atmospheric pressure to remove a small amount of methanol. The yield of methyl ester was 80.5%.

Embodiment 3

[0022] Example 3, respectively weighed tung oil 20g (0.026mol), methanol 10.11g (0.32mol), 1-(3-sulfopropyl)-2-pyrrolidone bisulfate 0.8g (0.0026mol) into the autoclave , the reaction temperature is 140° C., the reaction time is 8 hours, after the reaction, the mixture is allowed to stand for stratification, and the biodiesel phase is separated, and distilled at atmospheric pressure to remove a small amount of methanol, and the yield of methyl ester is 87.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com