Ultrasonic inspection method of back end of thick-wall aluminum alloy pipe

A detection method, ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve problems such as incomplete detection, improve detection accuracy and detection efficiency, improve accuracy and detection efficiency, and eliminate shrinkage residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific implementation mode 1: The specific steps of the ultrasonic detection method for tail shrinkage of aluminum alloy thick-walled tubes described in this implementation mode are as follows:

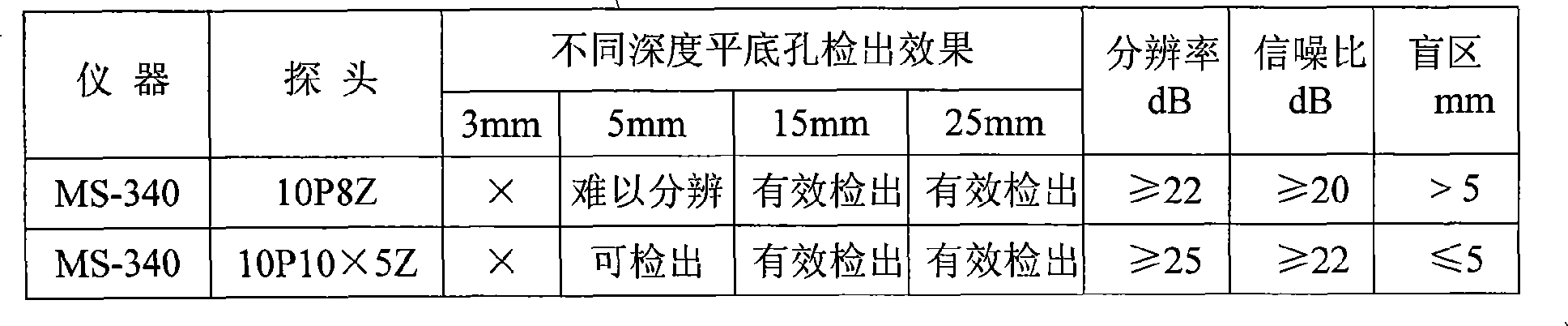

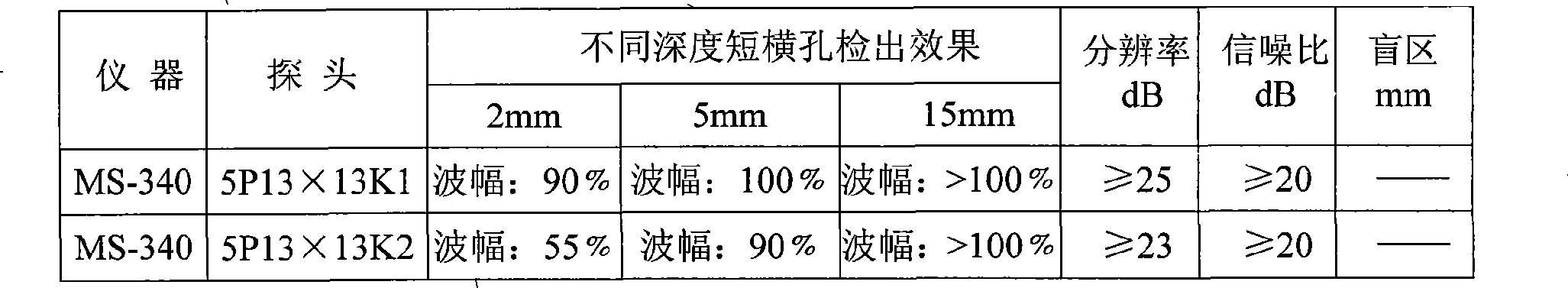

[0017] Step 1: According to the characteristics of thick-walled pipe shrinkage, select the ultrasonic detector and the supporting longitudinal wave straight probe and short front shear wave oblique probe;

[0018] Step 2: Comparison of the selection of sample tubes and hole making: Cut two sections of non-defective aluminum alloy thick-walled tube sample tubes with a length of 60mm, a wall thickness of 30mm, and an outer diameter of Φ150mm, according to the shrinkage shape and depth of the thick-walled tube Distribution characteristics, drilling Φ0.4mm flat-bottomed holes and Φ0.4×6mm short horizontal holes with different depths between 2 and 25mm;

[0019] Step 3: Make and debug the shear-wave oblique probe; grind the contact surface between the shear-wave oblique probe and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com