Device for cleaning vanadium-removing copper wire balls

A cleaning device and copper wire technology are applied in transportation and packaging, cleaning methods and utensils, cleaning methods using liquids, etc., which can solve the problems of great harm to the human body and the environment, high labor intensity, and low efficiency, and achieve good cleaning quality , reduce labor intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

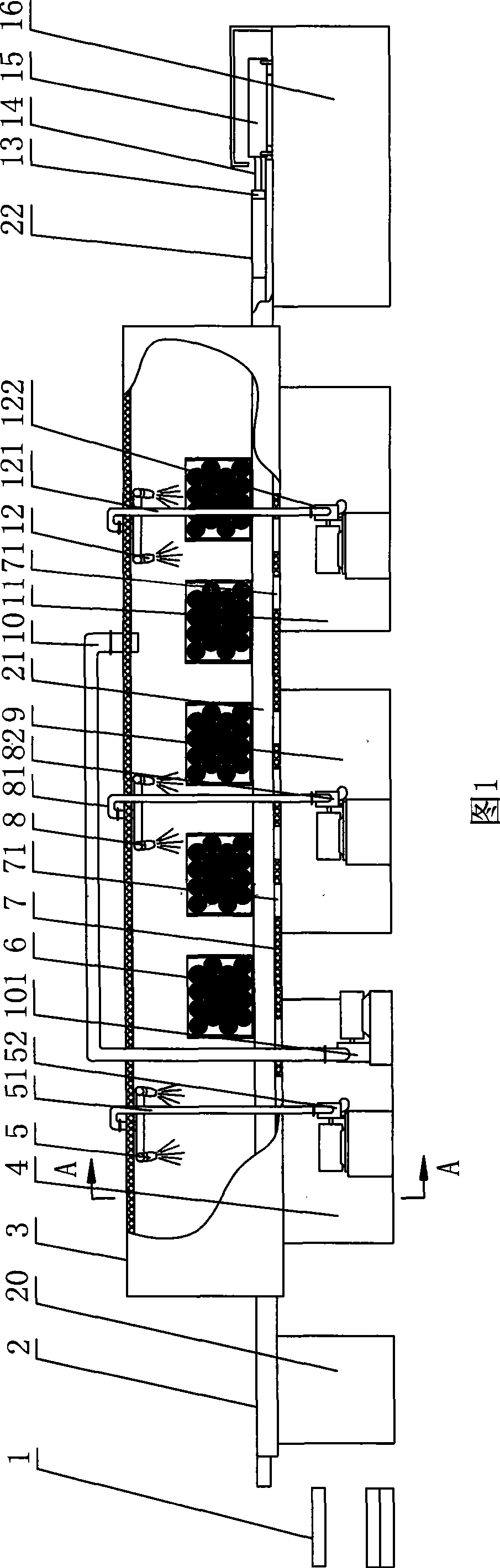

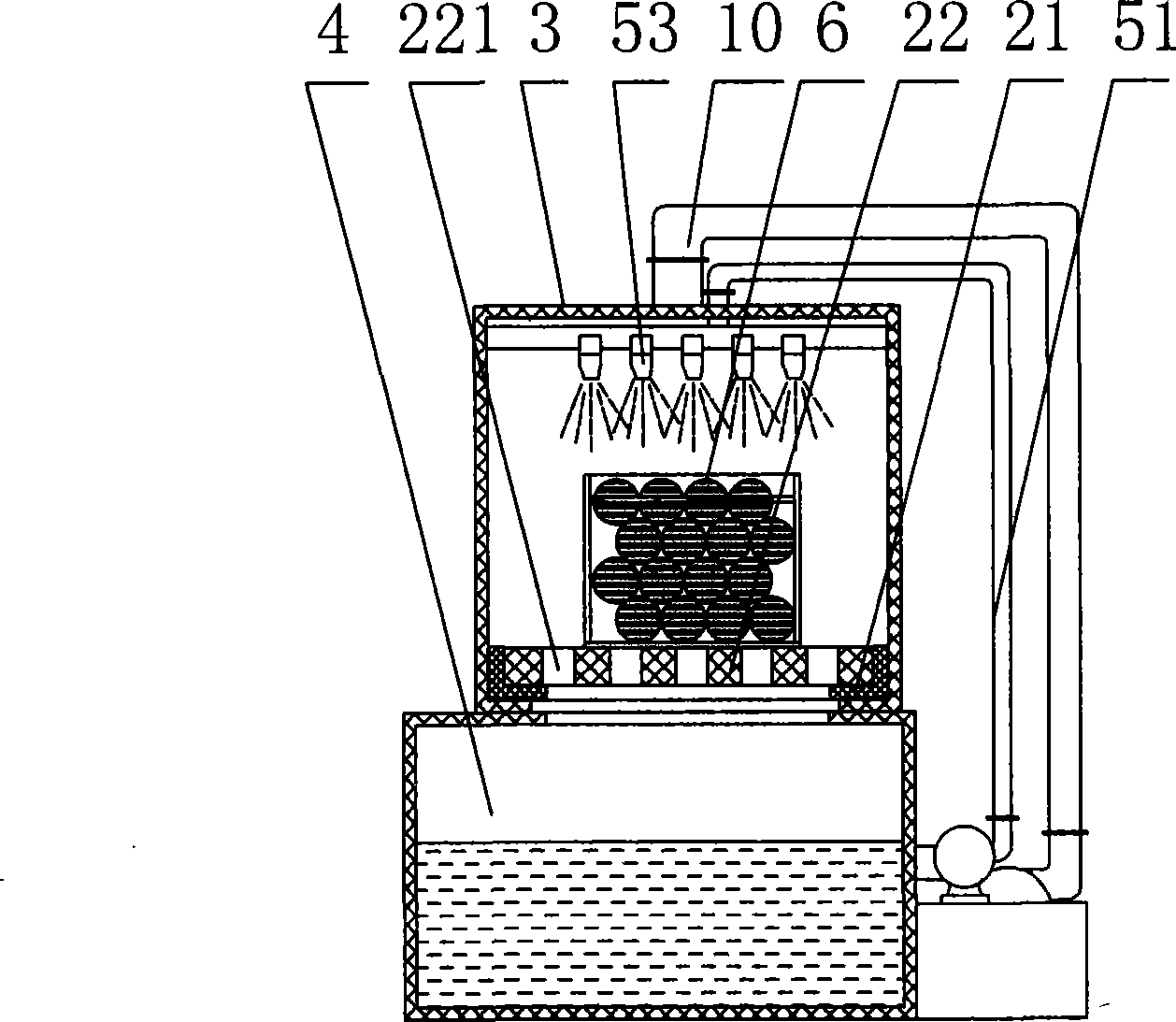

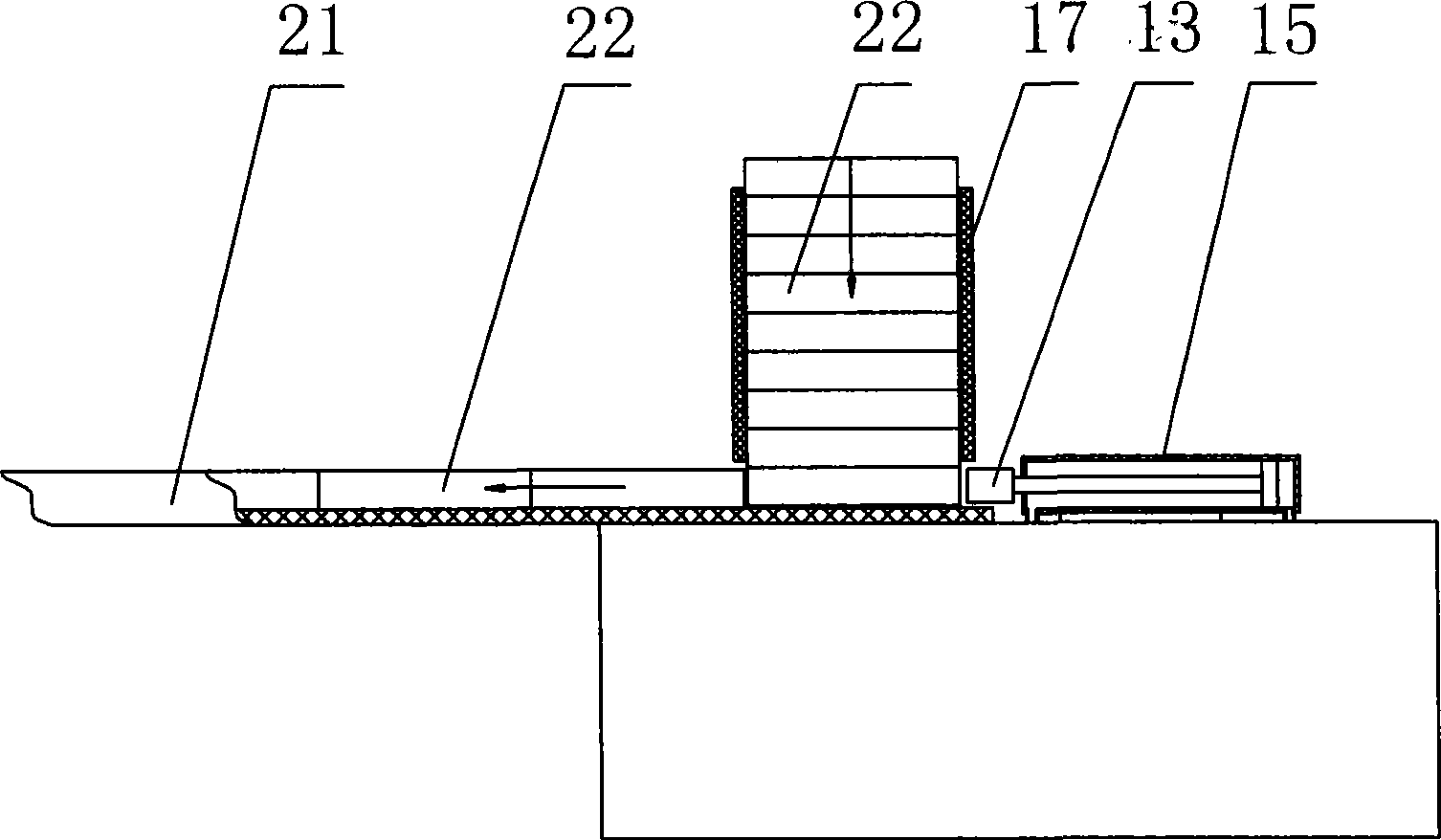

[0013] Fig. 1 is a schematic structural view of a preferred embodiment of the present invention, figure 2 Is its A-A sectional view. combined by Figure 1 and figure 2 It can be seen that the vanadium-removing copper wire ball cleaning device is mainly composed of frame 20, pickling liquid storage tank 11, rough cleaning liquid storage tank 9, fine cleaning liquid storage tank 4, tunnel 3, copper wire ball conveying mechanism 2, nozzle group 5 , 8, 12 and so on.

[0014] The pickling liquid storage tank 11, the rough cleaning liquid storage tank 9, and the fine cleaning liquid storage tank 4 are fixed on the floor. These tanks can be directly used as a part of the frame to support the tunnel 3. The tunnel 3 is linear and adopts acid-resistant The PP board is welded and its cross section is rectangular.

[0015] From the entrance of the tunnel 3, on the inner wall of the top of the tunnel 3, a group of pickling nozzles 12, a group of rough cleaning nozzles 8, and a group of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com